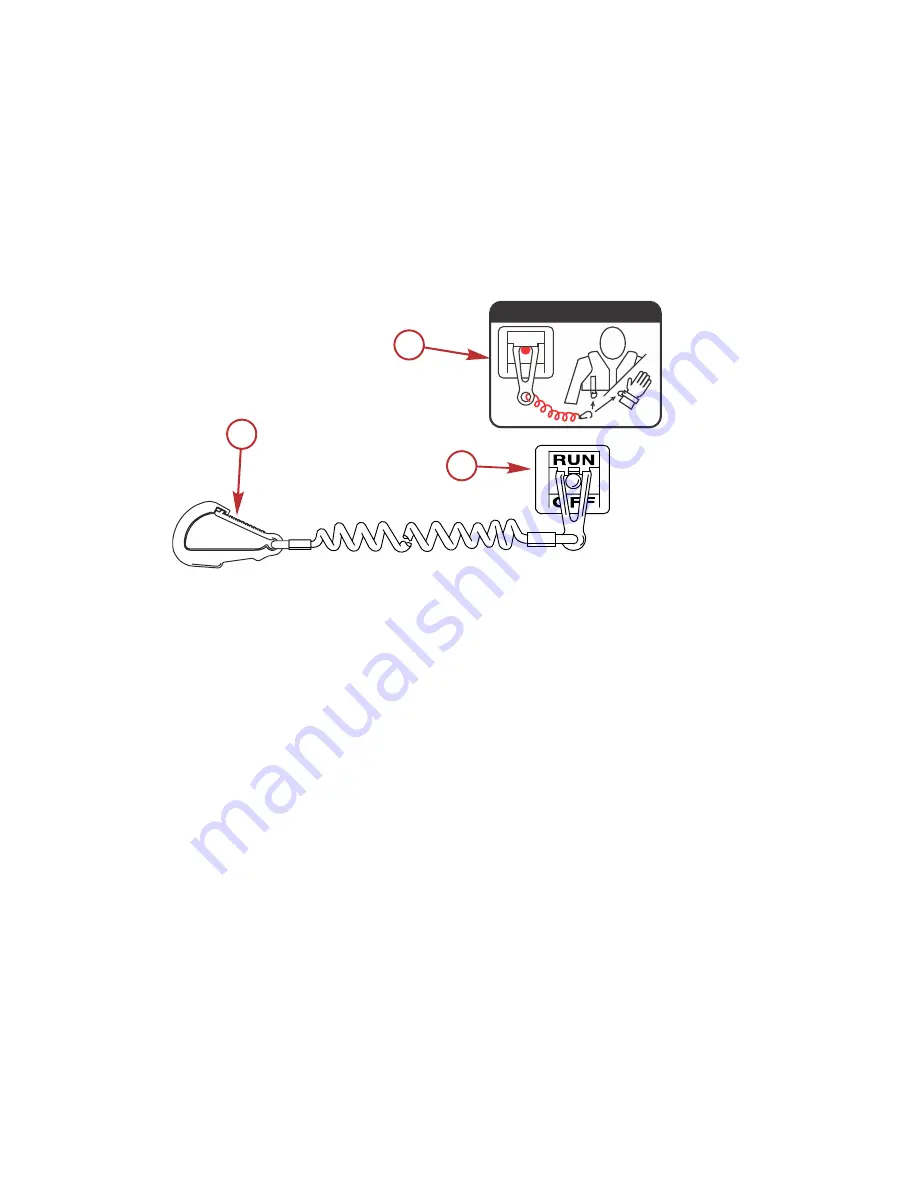

The lanyard cord is usually 122–152 cm (4–5 feet) in length when stretched out,

with an element on one end made to be inserted into the switch and a clip on

the other end for attaching to the operator's PFD or wrist. The lanyard is coiled

to make its at‑rest condition as short as possible to minimize the likelihood of

lanyard entanglement with nearby objects. Its stretched‑out length is made to

minimize the likelihood of accidental activation should the operator choose to

move around in an area close to the normal operator's position. If it is desired

to have a shorter lanyard, wrap the lanyard around the operator's wrist or leg,

or tie a knot in the lanyard.

a -

Lanyard cord clip

b -

Lanyard decal

c -

Lanyard stop switch

Read the following Safety Information before proceeding.

Important Safety Information:

The purpose of a lanyard stop switch is to stop

the engine when the operator moves far enough away from the operator's

position to activate the switch. This would occur if the operator accidentally falls

overboard or moves within the boat a sufficient distance from the operator's

position. Falling overboard and accidental ejections are more likely to occur in

certain types of boats such as low sided inflatables, bass boats, high

performance boats, and light, sensitive handling fishing boats operated by a

hand tiller. Falling overboard and accidental ejections are also likely to occur as

a result of poor operating practices such as sitting on the back of the seat or

gunwale at planing speeds, standing at planing speeds, sitting on elevated

fishing boat decks, operating at planing speeds in shallow or obstacle infested

waters, releasing your grip on a steering wheel or tiller handle that is pulling in

one direction, drinking alcohol or consuming drugs, or daring high speed boat

maneuvers.

c

a

b

53910

OFF

RUN

ATTACH LANYARD

GENERAL INFORMATION

eng

25

Summary of Contents for 150 FourStroke

Page 2: ...eng ...