MAINTENANCE

106

5. To remove minor scratches, use Mercury Marine Cowl

Finishing Compound (92-859026K 1).

Cleaning Care for the Powerhead (Saltwater Use)

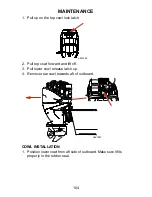

If the outboard is operated in saltwater, remove the top cowl and

flywheel cover. Inspect the powerhead and powerhead

components for salt build-up. Wash off any salt build-up from the

powerhead and powerhead components with fresh water. Keep

water spray out of the air filter/intake and alternator. After washing,

allow the powerhead and components to dry. Apply Quicksilver or

Mercury Precision Lubricants Corrosion Guard spray on the

external metal surfaces of the powerhead and powerhead

components. Do not allow the Corrosion Guard spray to come in

contact with the alternator drive belt, belt pulleys or the outboard

motor mounts.

IMPORTANT: Do not allow lubricant or Corrosion Guard spray to

come in contact with the alternator drive belt or the belt pulleys.

The alternator drive belt could slip and be damaged if it becomes

coated with any lubricant or Corrosion Guard spray.

Tube Ref No.

Description

Where Used

Part No.

120

Corrosion Guard

External metal

surfaces of the

powerhead and

powerhead

components.

92-802878-55

Battery Inspection

The battery should be inspected at periodic intervals to ensure

proper engine starting capability.

IMPORTANT: Read the safety and maintenance instructions

which accompany your battery.

1. Turn off the engine before servicing the battery.

2. Add water as necessary to keep the battery full.

3. Make sure the battery is secure against movement.

4. Battery cable terminals should be clean, tight, and correctly

installed. Positive to positive and negative to negative.

Summary of Contents for 200 VERADO

Page 4: ...iv ...