Section 5 - Storage

90-8M0133679

eng

JUNE 2017

Page 71

1. Supply cooling water to the water inlet holes or seawater pump inlet.

2. Start the engine and operate until it reaches normal operating temperature.

3. Stop the engine.

4. Change the engine oil and filter.

5. Start the engine and run for about 15 minutes. Check for oil leaks.

6. Flush the seawater cooling system. See

Flushing the Seawater System

.

Seasonal Storage

1. Read all precautions and perform all procedures found in

Preparing Your Power Package for Seasonal or Extended

Storage

.

2. Read all precautions and perform all procedures found in

Draining the Seawater System

and drain the seawater section

of the cooling system.

NOTICE

Water trapped in the seawater section of the cooling system can cause corrosion or freeze damage. Remove the boat from

the water to drain the seawater section of the cooling system immediately after operation or before any length of storage in

freezing temperatures.

IMPORTANT: We recommend the use of propylene glycol antifreeze in the seawater section of the cooling system for cold

weather (freezing temperature), seasonal storage, or extended storage. Make sure that the propylene glycol antifreeze

contains a rust inhibitor and is recommended for use in marine engines. Be certain to follow the propylene glycol

manufacturer's recommendations.

3. Fill a container with approximately 5.6 L (6.0 US qt) of propylene glycol antifreeze and tap water mixed to manufacturer's

recommendation to protect the engine to the lowest temperature to which it will be exposed during cold weather or

extended storage.

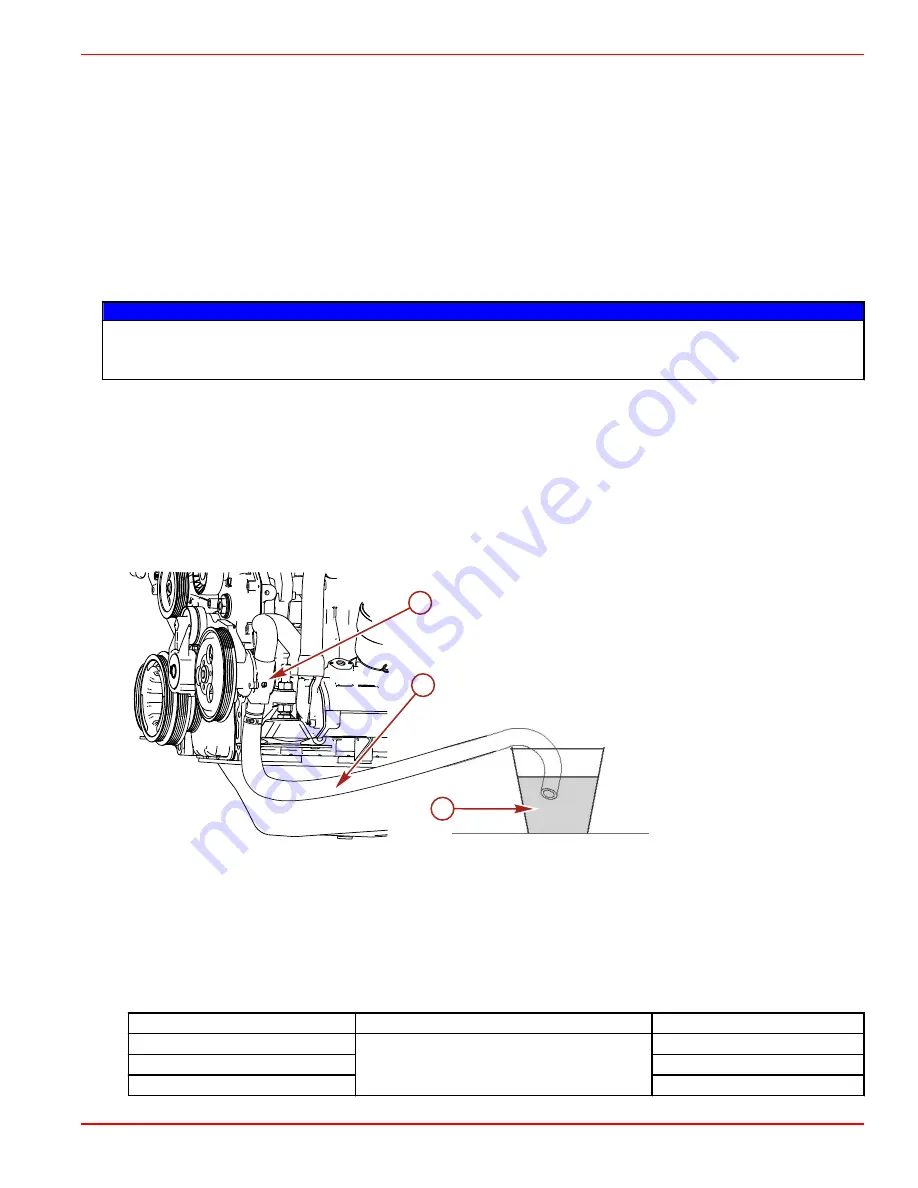

4. Disconnect the seawater inlet hose from the seawater pump. Using an adapter, if required, temporarily connect an

appropriate length piece of hose to seawater pump and place the other end of the hose into the container of propylene

glycol antifreeze and tap water.

Typical

a -

Seawater pump

b -

Temporary hose

c -

Container of propylene

glycol antifreeze and tap

water

IMPORTANT: Discharge of propylene glycol into the environment may be restricted by law. Dispose of propylene glycol in

accordance with federal, state, and local requirements.

5. Start the engine and operate at idle speed until the antifreeze mixture has been pumped into the engine seawater cooling

system.

6. Stop the engine.

7. Remove the temporary hose from the seawater pump.

8. Clean the outside of the engine and repaint any areas required with primer and spray paint. After the paint has dried, coat

the engine with the specified corrosion inhibiting oil or equivalent.

Description

Where Used

Part Number

Corrosion Guard

Outside of engine

92‑802878‑55

Light gray primer

92‑802878‑52

Mercury Diesel White

8M0108939

23452

a

b

c

Summary of Contents for MerCruiser Diesel Inboard 2.8L

Page 1: ...2 8L and 4 2L Diesel Inboard Models OPERATION MAINTENANCE MANUAL ...

Page 2: ......

Page 8: ...Page iv 90 8M0133679 eng JUNE 2017 ...

Page 20: ...Section 1 Getting to Know Your Power Package Notes Page 12 90 8M0133679 eng JUNE 2017 ...

Page 38: ...Section 3 Specifications Notes Page 30 90 8M0133679 eng JUNE 2017 ...

Page 92: ......