Section 2

Troubleshooting & Testing

MM-34

Page 12

Revised 11-02

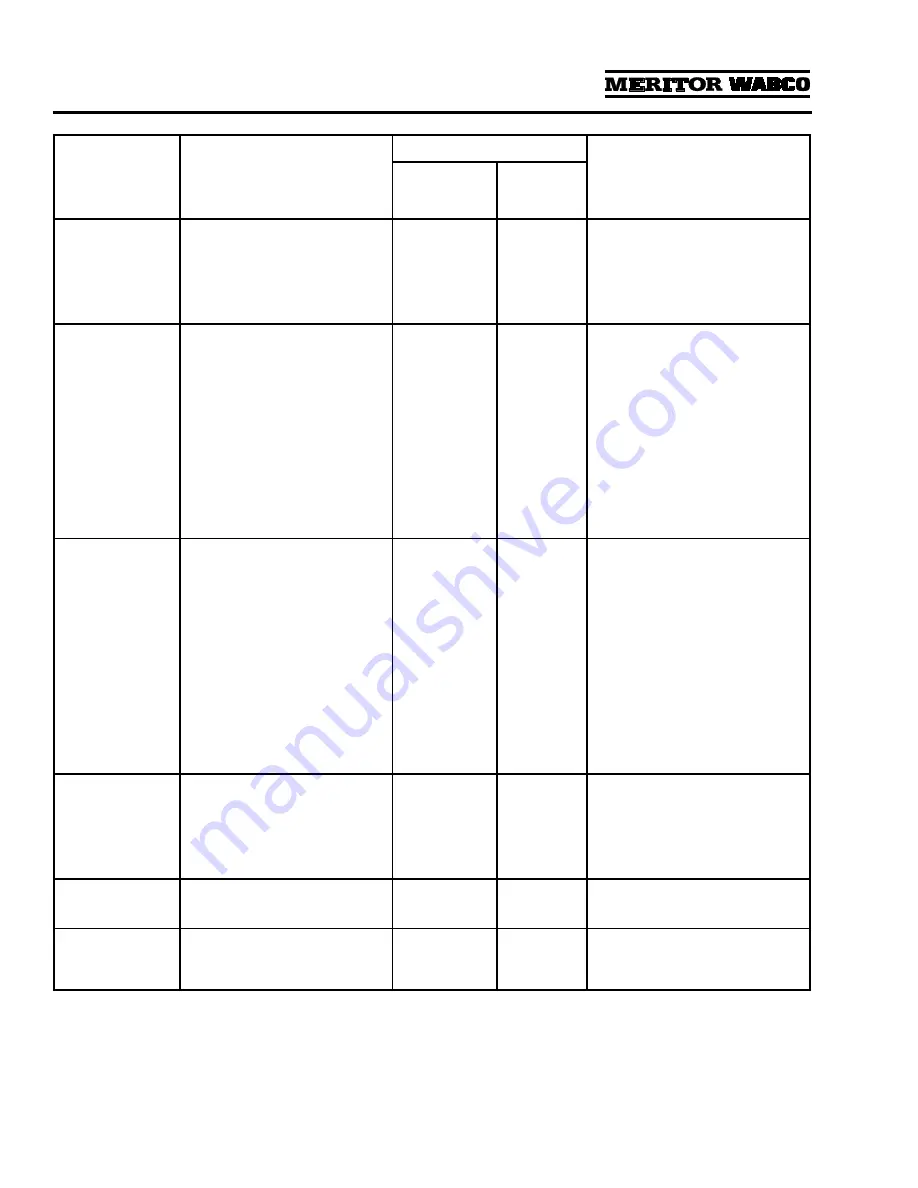

Air leak at turbo

cut-off valve vent.

Lip seal installed upside-down on

piston. Lip must face UP (towards

dryer).

Valve bore worn excessively.

Yes

Yes

Yes

Yes

Install lip seal correctly.

Inspect valve bore for wear. If a new

turbo cut-off valve does not seal in

a clean, lubricated bore, replace the

air dryer.

Air dryer frozen

(water collecting

in base of dryer is

freezing).

No electrical power to heater

connector.

Low voltage to heater connector.

Heater assembly not working.

Wrong voltage air dryer used; i.e.,

12-volt air dryer used in a 24-volt

system.

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Check for a blown fuse. Repair

heater circuit.

NOTE:

There must be power to the

heater connector the entire time the

vehicle’s ignition is

ON

.

Repair cause of low voltage, such

as poor electrical ground, bad

connections, corroded wire splices,

etc.

Replace heater assembly.

Replace with correct voltage air

dryer.

No air pressure

build-up in

system.

Air dryer not plumbed correctly

(connections reversed).

Wrong air line connected to dryer

port 4.

Air governor not working

properly.

Air system leaks, such as

compressor discharge line, air

dryer, reservoirs, brake or

suspension valves, etc.

Air dryer leaks from purge valve.

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Ensure compressor discharge line

is plumbed to air dryer port 1, and

air dryer port 21 is connected to

vehicle’s supply tank.

Ensure dryer port 4 line is

connected to the “UNL” port of the

air governor.

Inspect governor per

manufacturer’s instructions. Repair

or replace as needed.

Locate leak(s) and repair.

Refer to purge valve conditions

listed in this chart.

Water in tanks;

often following

aftermarket

installation or

when dryer is a

replacement for a

competitive brand.

Pressure-controlled check valve

not installed in correct tank or not

installed at all.

Pressure-controlled check valve

properly installed, but one-way

check valve not removed.

Yes

Yes

No

No

Install pressure-controlled check

valve in secondary tank.

Remove one-way check valve so

that only the pressure-controlled

check valve is installed between the

secondary tank and supply tank.

Water, oil, or

sludge in air

system tanks.

Desiccant contaminated with oil.

Yes

Yes

Replace desiccant. Inspect

compressor per manufacturer’s

instructions.

Water in system

tanks, everything

else checks out

okay.

Dryer not suitable for application.

Yes

Yes

Review application guidelines. For

assistance, call ArvinMeritor’s

Customer Service Center at

800-535-5560.

Condition

Possible Cause

Conditions May Occur In:

Solution

Regeneration

Style Air

Dryers

Dedicated

Purge Tank

Air Dryers