Section 2

Troubleshooting & Testing

MM-34

Page 10

Revised 11-02

Troubleshooting

Conditions you may experience, and suggested

solutions, appear in the following System Saver

Series Air Dryer Troubleshooting table.

NOTE:

The exploded view of the System Saver

single canister air dryer in Section 1 illustrates the

location of components in the dryer.

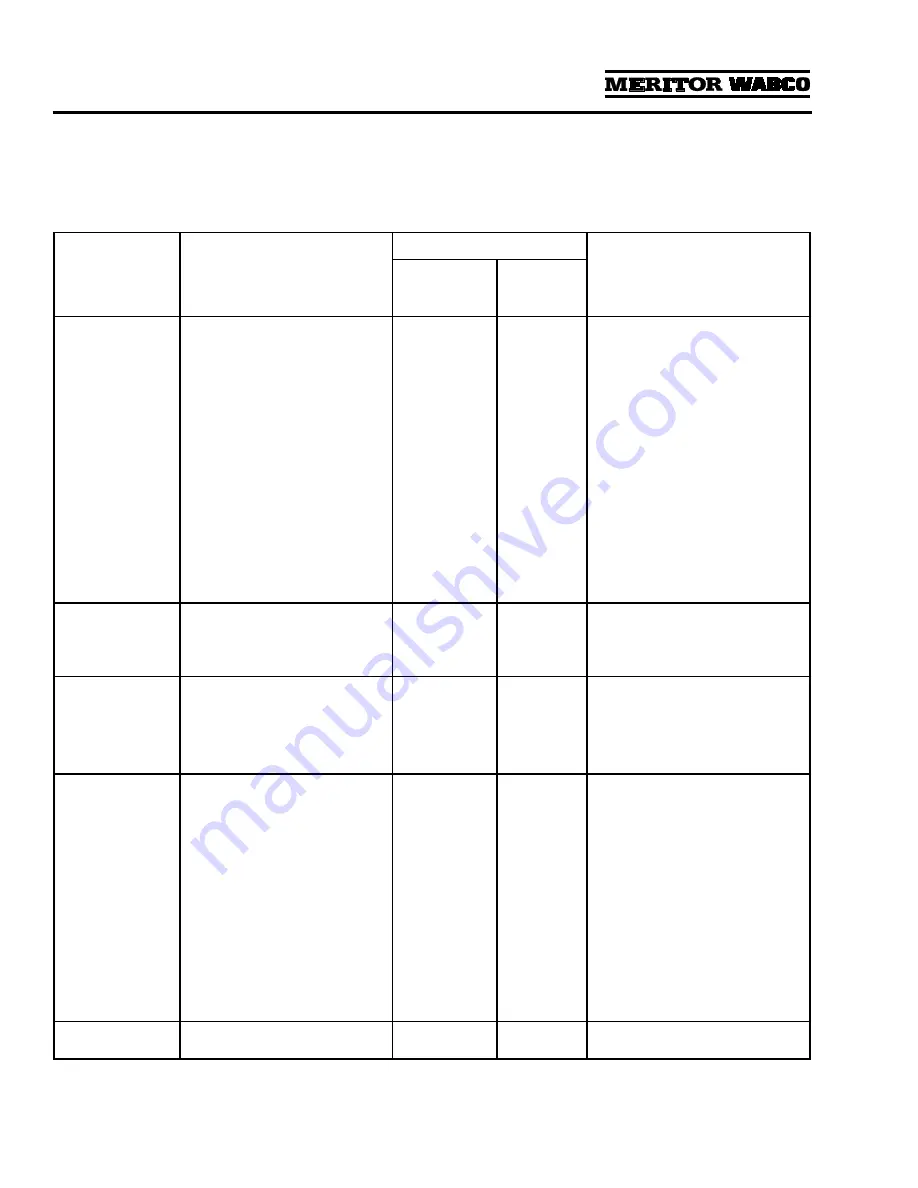

Condition

Possible Cause

Conditions May Occur In:

Solution

Regeneration

Style Air

Dryers

Dedicated

Purge Tank

Air Dryers

Dryer leaks from

purge valve during

compressor

loaded cycle. The

leak may cause

excessive

compressor

cycling or prevent

the system from

building air

pressure.

Purge valve frozen open (cold

weather operation).

Debris under purge valve seat,

such as particles from fittings or

air inlet line.

Purge valve washer installed

upside-down.

Wrong air line connected to dryer

port 4 (unloader port).

Purge valve snap ring not fully

seated in groove.

Yes

Yes

Check heater. Repair/replace if

necessary. Make sure governor to

dryer port 4 line is free of water/oil.

Remove and inspect purge valve

and clean water/oil from top of

piston.

Disassemble and clean purge valve.

Remove cartridge and clean dryer

sump area.

Ensure lip on aluminum washer

faces

DOWN

, away from dryer.

Verify correct air line installation

and correct as needed.

Seat snap ring fully into groove.

Slight leak from

purge valve. After

several hours, the

supply tank may

be empty.

Outlet check valve not seating or

regeneration valve not shutting

off regeneration airflow.

Yes

No

Remove, inspect, and clean outlet

check valve and regeneration valve

diaphragm. Replace if worn or

damaged.

Regeneration

cycle too long

(more than

30 seconds),

accompanied by

loss of pressure in

the supply tank.

Outlet check valve not seating.

Regeneration valve not shutting

off regeneration airflow.

Yes

Yes

Yes

No

Inspect and replace outlet check

valve as needed.

Replace regeneration valve.

Regeneration

cycle too short

(less than

10 seconds).

High air system demands during

compressor unloaded cycle.

Pressure-controlled check valve

not installed in system or not

working properly.

One-way check valve installed in

system reservoir instead of, or

with, pressure-controlled check

valve.

Regeneration valve not working.

Air governor not working

properly.

Yes

Yes

Yes

Yes

Yes

Yes

No

No

No

Yes

Increase air system capacity or

reduce air demands.

Check and replace pressure-

controlled check valve as needed.

Remove one-way check valve. Make

sure pressure-controlled check

valve is installed correctly.

Remove regeneration valve and

clean oil from diaphragm. If no oil

or other contaminants are present,

replace regeneration valve

assembly.

Inspect per manufacturer’s

instructions and repair/replace as

needed.

Water in purge

tank

Block in purge tank line.

N/A

Yes

Clear blockage. Replace desiccant

cartridge.