Section 2

Troubleshooting & Testing

MM-34

Page 14

Revised 11-02

2.

During the regeneration cycle, which lasts

from 10-25 seconds, supply and secondary

tanks will drop approximately 10 psi in

pressure. Check the secondary air gauge on

the vehicle dash panel to

verify this drop

.

NOTE:

A 10 psi drop in pressure in the

secondary air system is normal for Meritor

WABCO System Saver Series regeneration

style air dryers. There should be no visible

pressure drop for P Series dryers. If there is a

visible pressure drop (P Series dryer), perform

a check valve leak test on the system check

valves.

Step 3 applies to regeneration style air dryers only.

3.

If there is no drop in pressure, one of the

following conditions may apply:

O

Pressure-controlled check valve not

installed, or installed on wrong air tank.

O

Pressure-controlled check valve installed to

a one-way check valve, instead of

in place of

a one-way check valve.

O

There is another check valve located

between the air dryer and the secondary air

tank, usually at the supply tank.

O

Secondary air gauge not plumbed to the

secondary air system. Use a calibrated air

gauge in the secondary tank to check air

pressure.

— Make the necessary installation changes

or repairs and repeat the operational test.

O

If the secondary pressure drops 25 psi or

more during the regeneration cycle — and

there are no other air-operated components

using air during this cycle — there are air

leaks or other air system problems.

— Identify and repair all air leaks and air

system problems.

— Clean the Regeneration and Outlet Check

valves.

— Disconnect the compressor line from the

air dryer (Dryer Port 4). Check the

compressor and governor per the

manufacturer’s recommendation.

Pressure-Controlled Check Valve

Test — Regeneration Style Only

1.

Turn off the engine after the air system reaches

cut-out pressure (approximately

120 psi) and the air compressor has unloaded.

2.

Drain the supply tank down to 80 psi or lower.

3.

Check the secondary tank air gauge. It should

read 95 ± 5 psi.

NOTE:

A drop from 120 to 95 ± 5 psi during

this test is normal for vehicles equipped with

the System Saver Series air dryer and a

pressure-controlled check valve.

4.

If the secondary tank air gauge reading is less

than 90 psi:

O

Pressure-controlled check valve may be

installed backwards (arrow on valve must

point toward host reservoir). Make

necessary corrections and retest.

O

Check for leaks in the secondary air system.

Identify and repair any leaks.

5.

If the secondary tank air gauge reading does

not change — or the reading does not drop

below 100 psi:

O

Pressure-controlled check valve not

installed, or installed on wrong air tank.

O

Pressure-controlled check valve installed

TO

a one-way check valve, rather than

IN PLACE

OF

a one-way check valve.

O

There is another check valve located

between the air dryer and the secondary air

tank, usually at the supply tank.

O

Secondary air gauge not plumbed to the

secondary air system. Use a calibrated air

gauge in the secondary tank to check air

pressure.

— Make the necessary installation changes

or repairs and repeat the operational

test.

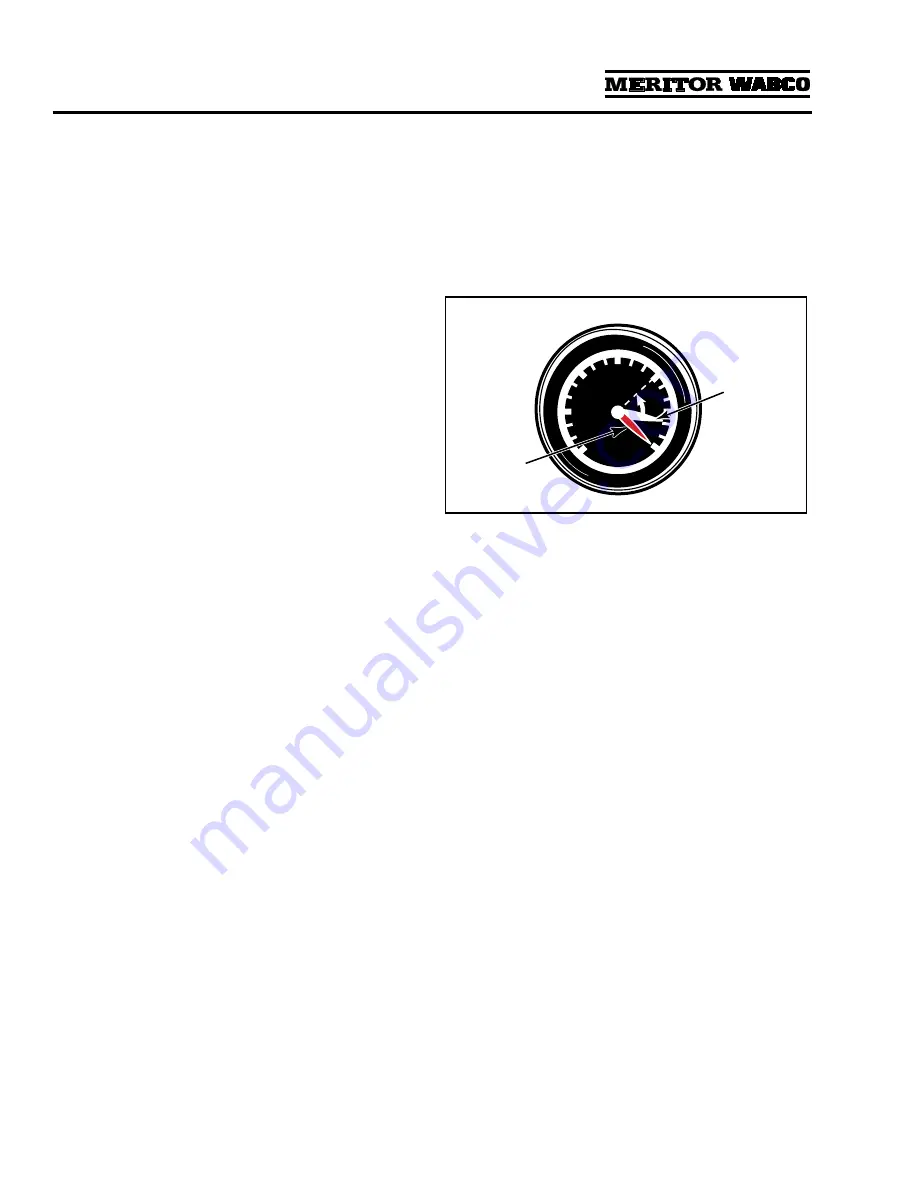

Figure 2.4

PSI

20

40

60

80

95

110

120

1002162a

Primary

Air Supply

(Red)

Secondary

Air Supply

(White)