29

Meritor

Wheel end assembly

Hollow shaft

3

Part 1 - Hub reduction with 3 - 4 planets

Wheel end with unitized bearing

Fig. 3.22

Fig. 3.21

Fig. 3.24

Fig. 3.23

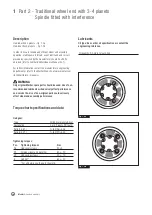

Apply sealing compound in

approx. 6mm diameter.

Bead (Dow Corning 7091) to the inner face of the cover plate in a

continuous bead (as showed between internal circumference ribs

and holes). Fig. 3.21

The components must be assembled immediately to permit the

silicone gasket material to compress evenly between the mating

surfaces. Refit the cover plate on the end of the hub casing and

retain with screws. Torque: 20 ± 5Nm

Fig. 3.22

Fill hub with 2.5 litres of oil as specified by vehicle manufacturer.

Fit new oil drain plug. Torque: 80Nm ± 20Nm

Fig. 3.23 - Hollow shaft

Fig. 3.24 - Solid shaft

NOTE

: with new hub cap there is an oil level line that aligns with

the bottom of the filler hole. When line is horizontal it is an

indication of permitted oil capacity.

Solid shaft

Summary of Contents for MM-0164

Page 20: ...20 Meritor Wheel end assembly ...

Page 30: ...30 Meritor Wheel end assembly ...

Page 38: ...38 Meritor Wheel end assembly ...

Page 54: ...54 Meritor Wheel end assembly ...

Page 62: ...62 Meritor Wheel end assembly ...

Page 63: ...63 Meritor Wheel end assembly pg 2 Part 3 Wheel end disassembly 64 Wheel end disassembly ...

Page 82: ...82 Meritor Wheel end assembly ...

Page 85: ...85 Meritor Wheel end assembly 4 Troubleshooting and Service Tools Mounting tool ...