60

Meritor

Wheel end assembly

Description

Hub reduction 3 planets - fig. 1.5a

Hub reduction 4 planets - fig. 1.5b

In order to ensure reliable and efficient wheel end assembly

operation, maintenance intervals, use of lubricants and correct

procedures specified by the manufacturer should be strictly

observed (refer to Lubrication Maintenance Manual no. 1).

For further information contact the manufacturer’s engineering

department or refer to the Meritor Web site at www.meritor.com

(Technical library - manuals).

WARNING

Only original Meritor spare parts should be used. Use of non-

recommended lubricants will adversely affect performance

and service life. Use of non-original parts could seriously

affect wheel end assembly performance.

Fig. 1.5a

Fig. 1.5b

Torque chart specifications and data

Hub gear:

Type

Cylindrical planetary gear

Designation

3 or 4 Planets (19 teeth)

Ratio (3.46:1)

1+(64/26)=3.46

Ratio (3.33:1)

1+(63/27)=3.33

Tightening torques:

Pos. Tightening torques

Nm

Wheel end screws

225±20

ABS Bracket

12Nm

28 Hub cover screws

20±5

29 Oil plugs (level and draining)

80 ± 20

32 Hub casing screws

40 ± 10

8 Hub nut *

64 ± 20

* For all details see the next chapter 8

1

2

3

1

2

3

4

Lubricants

Oil type: See carrier oil specification or contact the

engineering reference.

Oil quantity: 2.5 liters for each-hub

1

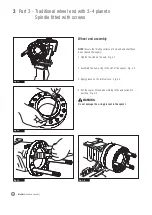

Part 3 - Traditional wheel end with 3-4 planets

Spindle fitted with screws

Summary of Contents for MM-0164

Page 20: ...20 Meritor Wheel end assembly ...

Page 30: ...30 Meritor Wheel end assembly ...

Page 38: ...38 Meritor Wheel end assembly ...

Page 54: ...54 Meritor Wheel end assembly ...

Page 62: ...62 Meritor Wheel end assembly ...

Page 63: ...63 Meritor Wheel end assembly pg 2 Part 3 Wheel end disassembly 64 Wheel end disassembly ...

Page 82: ...82 Meritor Wheel end assembly ...

Page 85: ...85 Meritor Wheel end assembly 4 Troubleshooting and Service Tools Mounting tool ...