75

Meritor

Wheel end assembly

3

Part 3 - Traditional wheel end with 3-4 planets

Spindle fitted with screws

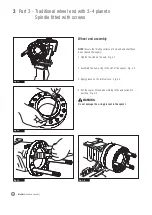

14. When the clevis and the lever are correctly positioned, tighten

the wheel and screws in cross with a torque wrench. Fig. 3.14

The torque of the new screw wheel should be 225 ± 20Nm.

15. Tighten the new screws of "L" brackets with a torque wrench.

The torque of the new screw wheel should be 175 ± 25Nm.

Fig. 3.15

16. Tighten the lever pinch bolt/nut. The torque of the new nut

wheel should be 55 ± 75Nm. - Fig. 3.16

17. Tighten the lever on the camshaft. The torque of the new

screw wheel should be 48 ± 8 Nm. - Fig. 3.17

18. Refit a new outer O-ring on the hub using grease as lubricant.

Fig. 3.18

Fig. 3.14

Fig. 3.15

Fig. 3.16

Fig. 3.17

Fig. 3.18

O Ring

Summary of Contents for MM-0164

Page 20: ...20 Meritor Wheel end assembly ...

Page 30: ...30 Meritor Wheel end assembly ...

Page 38: ...38 Meritor Wheel end assembly ...

Page 54: ...54 Meritor Wheel end assembly ...

Page 62: ...62 Meritor Wheel end assembly ...

Page 63: ...63 Meritor Wheel end assembly pg 2 Part 3 Wheel end disassembly 64 Wheel end disassembly ...

Page 82: ...82 Meritor Wheel end assembly ...

Page 85: ...85 Meritor Wheel end assembly 4 Troubleshooting and Service Tools Mounting tool ...