77

Meritor

Wheel end assembly

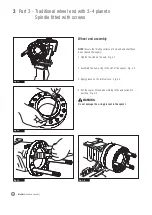

25. Locate the ring gear carrier into position. Assembly ring gear

group. - Fig. 3.24

NOTE

: If available, use a lifting tool

WARNING:

Do not damage the thread of the wheel end spindle.

26. Install and tighten wheel-bearing nut, while rotating wheel

back & forth. Further rotate wheel (3) revolutions each

direction alternating fwd/rev. Mark nut position and retighten

it.

If nut turns, repeat previous step until nut no longer turns

when retightened. Use a torque wrench on wheel end.

The torque of the new nut wheel should be 64 ± 20Nm.

Fig. 3.25

Alternative method:

applied as present in the picture here

below. In this test modality, the linear force range should be

10 ÷ 28N. - Fig. 3.26

NOTE

: If the torque is outside the spec, return at the previous

point and readjust it.

27. When the wheel end torque is in the specification use a

staking tool to stake nut lip into keyway in spindle.

Fig. 3.27

Fig. 3.24

Fig. 3.25

Fig. 3.26

Fig. 3.27

3

Part 3 - Traditional wheel end with 3-4 planets

Spindle fitted with screws

Summary of Contents for MM-0164

Page 20: ...20 Meritor Wheel end assembly ...

Page 30: ...30 Meritor Wheel end assembly ...

Page 38: ...38 Meritor Wheel end assembly ...

Page 54: ...54 Meritor Wheel end assembly ...

Page 62: ...62 Meritor Wheel end assembly ...

Page 63: ...63 Meritor Wheel end assembly pg 2 Part 3 Wheel end disassembly 64 Wheel end disassembly ...

Page 82: ...82 Meritor Wheel end assembly ...

Page 85: ...85 Meritor Wheel end assembly 4 Troubleshooting and Service Tools Mounting tool ...