Maintenance Manual MM-0230

Copyright 2002

Issued 07-02

ArvinMeritor, Inc.

Page 21

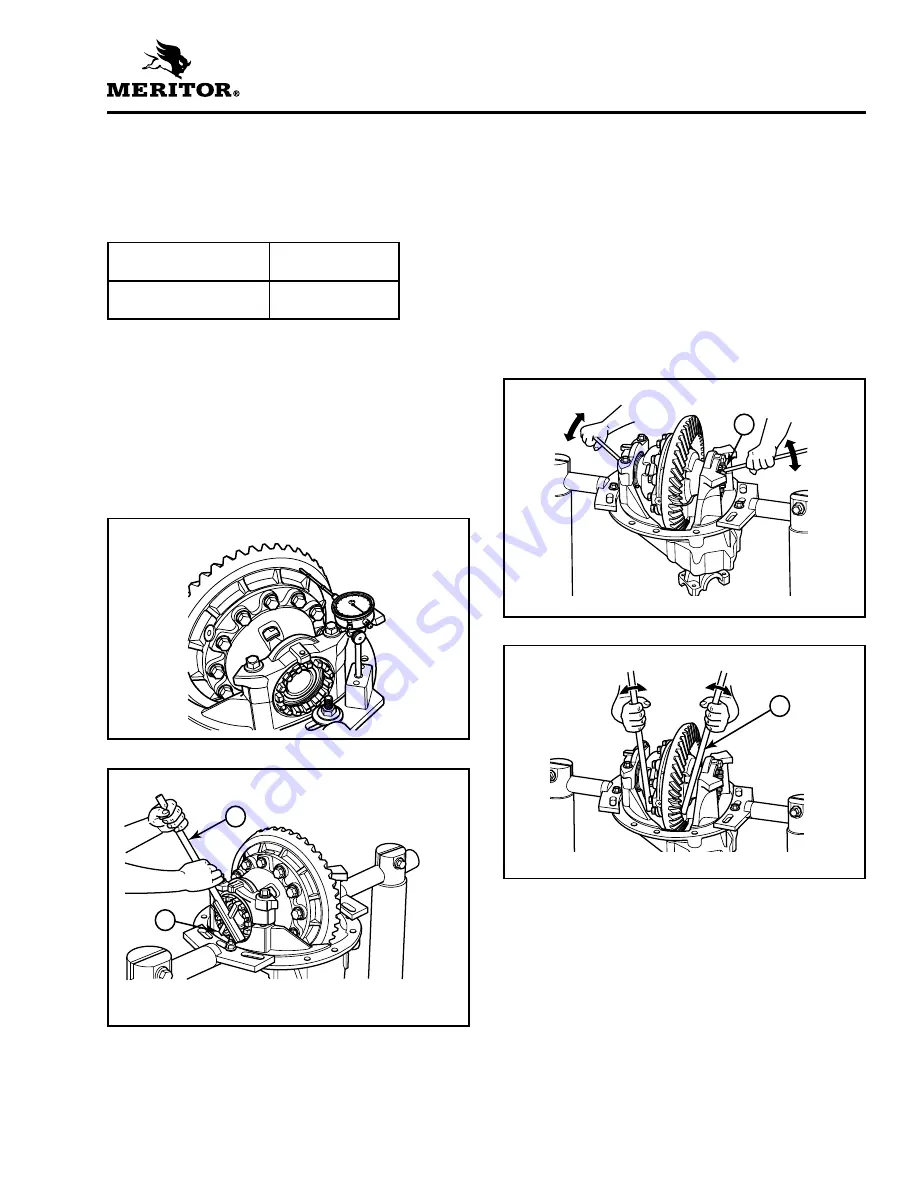

Adjust Differential Bearing Preload

Use Method 1 or Method 2 below to adjust

differential bearing preload.

Specifications

Method 1

1.

Attach a dial indicator onto the carrier

mounting flange so that the pointer is against

the ring gear’s back surface. Figure 4.12.

2.

Use a T-bar wrench to loosen the bearing

adjusting ring that is opposite the ring gear.

Figure 4.13. The dial indicator will show a

small amount of end play.

3.

Use one of the following procedures to move

the differential and ring gear to the LEFT and

RIGHT while you read the dial indicator.

A. Insert two pry bars between the bearing

adjusting rings and the ends of the

differential case. Figure 4.14. The pry bars

must not touch the differential bearings.

B. Insert two pry bars between the differential

case, or the ring gear and the carrier at

locations other than specified in Step A.

Figure 4.15. The pry bars must not touch

the differential bearings.

4.

Tighten the bearing adjusting ring until the dial

indicator reads ZERO end play. Move the

differential ring to the LEFT and RIGHT as

needed. If necessary, repeat Step A or B.

5.

Tighten each bearing adjusting ring one notch

from ZERO. Proceed to Check Ring Gear

Runout (Radial Movement) in this section.

Differential bearing

preload

15-35 lb-in

(1.7-3.5 N•m)

Expansion between

bearing caps

0.006-0.013-inch

(0.15-0.33 mm)

Figure 4.12

Figure 4.13

1

T-BAR WRENCH

2

ADJUSTING RING OPPOSITE RING GEAR

1

2

Figure 4.14

1

Pry bars must not touch bearings.

Figure 4.15

1

Pry bars must not touch bearings.

1

1