TP-9579B

16579

Revised 12-09

Printed in the USA

© Copyright Meritor Automotive, Inc., 2009

Page 3

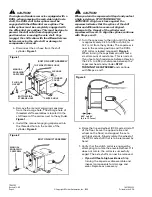

7.

Identify each axle shaft so they can be installed

in the same location after transporting or repair

is completed. (Example: Match mark a mating

axle shaft and hub.)

8.

Remove the stud nuts or capscrews and the

washers from the flange of the axle shaft.

Figure 4

.

9.

Loosen the tapered dowels, if used, in the

flange of the axle shaft using one of the two

following methods.

Figure 4

.

CAUTION

Do not use a chisel or wedge to loosen the axle

shaft and dowels. The chisel or wedge can damage

the hub, axle shaft and gasket, if used.

Brass Drift Method:

WARNING

Do not strike the round driving lugs on the flange

of an axle shaft. Pieces can break off and cause

serious personal injury.

NOTE:

A 1.5-inch (38.1 mm) diameter brass

hammer can be used as a drift.

a. Hold a 1.5-inch (38.1 mm) diameter brass

drift against the center of the axle shaft

flange, INSIDE THE ROUND DRIVING LUGS.

Figure 5

.

b. Hit the end of the drift with a large hammer

(5 to 6 pounds, 2.3 to 2.7 kg) to loosen the

axle shaft and tapered dowels from the hub.

Figure 5

.

Air Hammer Method:

WARNING

To prevent serious eye injury, always wear safe eye

protection when you perform vehicle maintenance

or service.

a. Use an air hammer, such as Chicago

Pneumatic CP-4181-PULER, or equivalent,

with a round hammer bit to loosen the axle

shaft and dowels.

b. Put the round hammer bit against the axle

shaft flange between the studs, at different

points around the flange. Operate the air

hammer at each location and loosen the axle

shaft and tapered dowels from the hub.

Figure 6

.

Figure 4

STUD NUT

WASHER

DOWEL

GASKET

STUD

ROUND

DRIVING

LUGS

CAPSCREW

WASHER

AXLE SHAFT

(FLANGE)

HUB

Figure 5

Figure 6

ROUND DRIVING LUG

AIR HAMMER

AND BIT