TP-9579C

Revised 12-09

16579/22882

Page 4

© Copyright Meritor Automotive, Inc., 2009

Printed in the USA

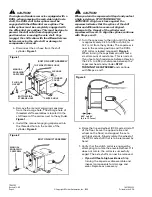

10. Remove the tapered dowels, the axle shafts

and gaskets (if used).

Figure 4

.

11. Remove the remaining axle shaft(s) as

necessary from the axle(s) that will remain on

the road when the vehicle is transported

according to Table A.

12. Install a cover over the open end of each hub

where an axle shaft was removed. This will

prevent dirt from entering the bearing cavity

and minimize loss of lubricant.

NOTE:

If an air supply will be used for the brake

system of the transported vehicle, continue with

Steps 13 and 14, otherwise continue with Step 15.

13. Connect an auxiliary air supply to the brake

system of the vehicle that is being transported.

Before moving the vehicle, charge the brake

system with the correct amount of air pressure

to operate the brakes. Refer to the instructions

supplied by the manufacturer of the vehicle for

procedures and specifications. If an auxiliary

air supply is not used, continue with Step 15.

14. When the correct amount of air pressure is in

the brake system, release the parking brakes of

the vehicle that is being transported. Step 15 is

not required.

WARNING

When you work on a spring chamber, carefully

follow the service instructions of the chamber

manufacturer. Sudden release of a compressed

spring can cause serious personal injury.

15. If there are spring (parking) brakes on the

axle(s) that will remain on the road when the

vehicle is transported, and they cannot be

released by air pressure, manually compress

and lock each spring so that the brakes are

released. Refer to the manufacturer’s

instructions.

After Towing or

Drive-Away (Piggybacking)

WARNING

To prevent serious eye injury, always wear safe eye

protection when you perform vehicle maintenance

or service.

WARNING

Engage the parking brake to prevent the vehicle

from moving before you begin maintenance or

service procedures that require you to be under

the vehicle. Serious personal injury can result.

1.

If an auxiliary air supply was used, apply the

vehicle parking brakes using the switch inside

the cab of the vehicle. If an auxiliary air supply

was not used, begin with Step 2.

WARNING

When you work on a spring chamber, carefully

follow the service instructions of the chamber

manufacturer. Sudden release of a compressed

spring can cause serious personal injury.

2.

Apply the vehicle spring (parking) brakes by

manually releasing each spring that was

compressed before transporting started. Refer

to manufacturer’s instructions.

3.

Disconnect the auxiliary air supply, if used,

from the brake system of the vehicle that was

transported. Connect the vehicle’s air supply to

the brake system.

4.

Remove the covers from the hubs.

NOTE:

Install the axle shafts indicated in

Table B

.

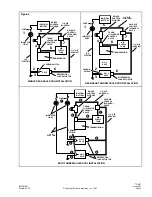

Axle shafts with a DCDL have a double row of

splines that engage with splines of the side gear

and of the shift collar in the differential case.

Figure 7

. Continue with Step 5.

NOTE:

Make sure to engage the axle shaft splines

for the differential side gear and the shift collar.

They must be fully engaged.

5.

Install the gasket, if used, and axle shaft into

the axle housing and carrier in the same

location it was removed from. The gasket and

flange of the axle shaft must be flat against the

hub. Rotate the axle shaft and/or the driveline

as necessary to align the splines and the holes

in the flange with the studs in the hub.

Figure 4

.

6.

Install the dowels, if used, over each stud and

into the tapered holes of the flange.

Table B

Single Axles

Remove both axle shafts.

Tandem Axles

Forward Axle (Towing from Front):

No need to remove axle shafts.

Forward Axle (Towing from Rear):

Remove both axle shafts.

Rear Axle (Towing from Front):

Remove both axle shafts.

Rear Axle (Towing from Rear):

No need to remove axle shafts.