USING YOUR OPENER

1. Your opener can be activated by any of the following devices:

•

Opener control panel

: Up and Down Buttons and Green O.S.C.

•

The Outside Keyswitch or Keyless Entry System

(if you have

installed either of these accessories).

•

The Remote Control Transmitter.

Hold the push button down until

the door starts to move.

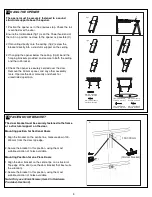

2. Opening the Door Manually: Door should be fully closed if

possible. Weak or broken springs could allow an open door to

fall rapidly. Property damage or serious personal injury could

result.

NOTE: For full instructions on how to operate the door manually

refer to section 17.

The door can be opened manually by pulling the release handle

down. To reconnect the door, press the Green button in the centre of

the trolley assembly.

Do not use the manual release handle to pull the door open

or closed.

3. When the Opener is Activated by Remote Control:

1. If open, the door will close. If closed, the door will open.

2. If closing, the door will stop.

3. If opening, the door will stop (allowing space for entry and exit of

pets and for fresh air).

4. If the door has been stopped in a partially open or closed position,

it will reverse direction.

5. If an obstruction is encountered while closing, the door will reverse

to the UP limit.

6. If an obstruction is encountered while opening, the door will

reverse and stop.

7. The optional Protector System™ uses an invisible beam which,

when broken by an obstruction, causes a closing door to open

and prevents an open door from closing. It is STRONGLY

RECOMMENDED for homeowners with young children.

4. The opener lights will turn on under the following conditions:

when the opener is initially plugged in; when power is restored after

interruption or when the opener is activated.

Lights will turn off automatically after 2-1/2 minutes.

Once a Month

• Manually operate door. If it is unbalanced or binding, call a

qualified door technician.

• Check to be sure door opens & closes fully. Adjust limits

and/or force if necessary.

• Repeat the safety reverse test. Make any necessary

adjustments.

Once a Year

• Lightly grease the belt and inside the rail assembly where

the trolley slides.

• Internally the opener does not require additional lubrication.

• Lightly grease the belt and inside the rail assembly where

the trolley slides. Be careful to use gloves around any sharp

metal edge or the rail.

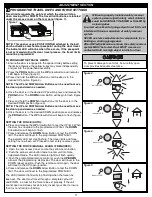

Battery of the remote control:

The batteries in the remote have an extremely long life.

If the transmission range decreases, the batteries must be

replaced. Batteries are not covered by the warranty.

Replacing battery (CR2032):

To replace battery, turn remote control around and open the

case with a screwdriver. Lift cover and lift control board below.

Slide battery to one side and remove. Observe polarity of

battery!

Assemble again in reverse direction.

REPLACE BATTERIES IN REMOTES

12

VD

C

Pb

Cd

Hg

CARE OF YOUR OPENER

To prevent SERIOUS INJURY OR DEATH:

observe the following instructions for the

battery

- NEVER allow small children near batteries.

- If battery is swallowed, immediately notify doctor.

- Danger of explosion if battery is replaced improperly.

- Replacement only by identical or equivalent type.

- Dispose of old battery properly. Batteries should not

be treated as household waste. All consumers are

required by law to dispose of batteries properly at the

designated collection points.

- Never recharge batteries that are not meant to be

recharged.

- Do not short-circuit batteries or take them apart.

- If necessary, clean contacts on batteries and contacts

before loading.

- Never expose batteries to excessive heat such as

sunshine, fire or the like!

17

29

31

30

or

Carefully

Remove Battery

(CR2032 x 1)

MAINTENANCE AND CARE OF YOUR OPENER

To replace battery for optional remote control transmitters -

E943M, E940M & E945M, use a screwdriver blade to pry

open the case as shown. Insert battery positive side up.