11

To prevent damage to vehicles, be sure fully open

door provides adequate clearance.

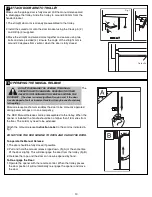

Travel limits regulate the points at which the door will stop

when moving UP or DOWN. The travel limit buttons are located

under the light cover (figure 1).

NOTE: The opener will MOVE AUTOMATICALLY after setting the

DOWN limit at step 6. A complete UP DOWN cycle is performed

in order to “Set the Force” automatically. If the door is

interrupted during this process, the force will not be set and

the process will have to be repeated.

REFER TO THE DIAGRAMS:

1. Turn the Power ON and open the light cover. (The courtesy LEDs

will be on during this operation, and you may need to cover these

in order to see the program buttons clearly).

2. Press the

“P”

button until LED 3 starts flashing.

3. Press and hold the

“+”

button until the door moves to the desired

UP

position.

The “+” and “-” buttons can be used to move the

door UP and DOWN if required.

4. Press the “P” button to set the UP limit. LED 2 starts flashing.

5. Press and hold the

“-”

button until the door moves to the desired

DOWN

position.

The “+” and “-” buttons can be used to move

the door UP and DOWN if required.

6. Press and release the

“P”

button to set the DOWN limit. At this

point the opener will operate AUTOMATICALLY a complete cycle.

This will set the force of the motor, all LED indicators will stop

after this operation.

LIMITS AND FORCE ARE NOW SET.

SETTING THE FORCE (MANUAL LEARN IF REQUIRED):

If the limits are already set, the force can be set manually if

required.

1. Start with the door closed.

2. Disconnect the mains power from the opener for approx.10

seconds.

3. Using the remote control, Open and Close the door one complete

cycle.

The Force Setting has now been set manually.

PROGRAM THE TRAVEL LIMITS AND FORCE SETTINGS

ADJUSTMENT SECTION

19

Without a properly installed safety reversal

system, persons (particularly small children)

could be SERIOUSLY INJURED or KILLED by

a closing door.

• Incorrect adjustment of garage door travel limits will

interfere with proper operation of safety reversal

system.

• NEVER use force adjustments to compensate for a

binding or sticking garage door.

• After ANY adjustments are made, the safety reversal

system MUST be tested. Door MUST reverse on

contact with 40 mm high object laid flat on floo

r.

S

P

1

2

3

S

P

1

2

3

S

P

1

2

3

S

P

1

2

3

S

P

1

2

3

1

2

3 2

1

2

3 2

1

2

3 2

1

2

3 2

1

2

3 2

2

3

4

5

6

-

+

P

S

1

3

2

3 2

2 1

-

+

P

S

1

3

2

3 2

2 1

1

▲

▐

▲

▐

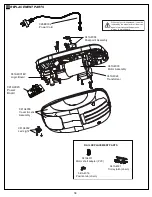

Connect Electric Power

TO AVOID INSTALLATION DIFFICULTIES, DO NOT RUN THE GARAGE DOOR OPENER UNTIL INSTRUCTED TO DO SO.

Connect to properly fused and earthed power outlet.

-

Ensure all ropes and installation tools have been removed from the door.

- When the opener is switched ON, the operator light flashes a number of times and then remains ON.