4

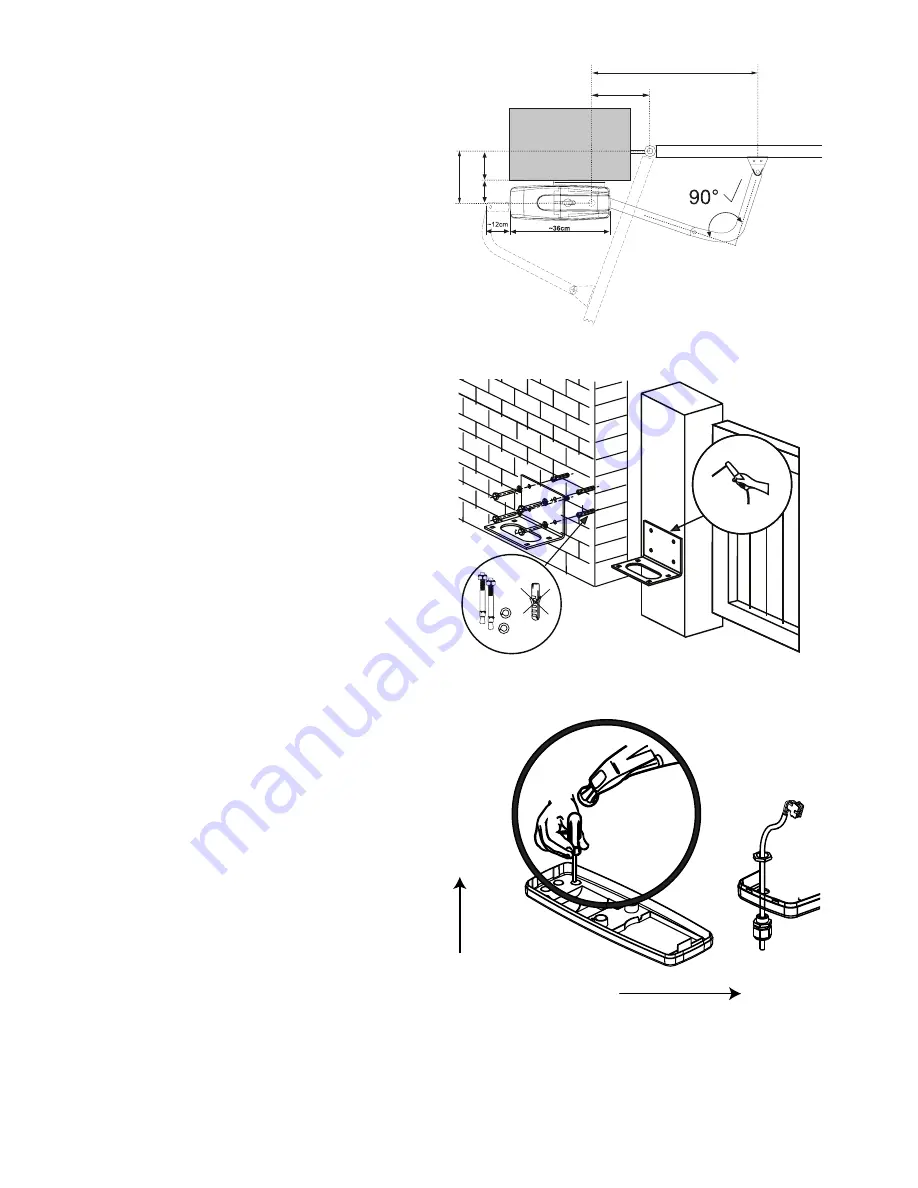

MOUNTING REQUIREMENTS

The gate drive mechanism is suitable for use in conjunction

with pillars with a max. thickness of 30cm. The amount of

room around the pier affects the opening angle and the po-

sition of the arms. The drive mechanism is equipped with

built-in limit stops for both the OPEN and CLOSE direc-

tions. A different opening angle can be set for the left-hand

wing as compared with the right-hand one

.

A

=3

8,

5c

m

8,

5c

m

30

cm

C

B=60-70cm

7-8 cm = 90°

max. 10 cm

=

INSTALLATION

Step 1 Install Motor Bracket

For Stone or reinforce concrete pillars use Dynabolts or

Chemical anchors (not supplied) to mount the motor sup-

port bracket onto the wall at the desired height. The gate

motor exerts a considerable force, ensure the wall is suit-

able. It may be necessary to use metal reinforcing, if so

weld the bracket onto the brace to prevent damage to the

wall and or motor.

If fastening to brickwork CHEMICAL ANCHORS should

be used and metal reinforcing is highly recomended.

DO NOT USE PLASTIC ANCHOR TO MOUNT THE

BRACKET IN PLACE.

Step 2 Prepare the Motor Housing

Taking note of the the Motorʼs orientation, carefully knock

out one of the four tap in the base housing as illustrated to

allow for cable entry. Several openings for the cable have

been pre-punched in the base and need only be broken

through. Place the base plate onto a solid surface whilst

breaking the holes through to prevent the PVC base plate

from breaking. A small, flat screwdriver should be used for

breaking the holes through. For this purpose, tap on the

screwdriver handle with the palm of the hand from the in-

side. Repeat this as necessary at several points on the pre-

marked circle. The pre-punched area can then be easily

removed and the strain relief supplied as standard fitted in

its place.

Thread the Terminated Loom through the gland nut and into

the hole knocked out for cable entry. Thread the gland over

the cable and through the knockout hole as illustrated. Fas-

ten the Gland in place firmly with the nut. Hand tighten the

bottom nut, allowing around 200mm of cable to protrude.

Knock out

PILLAR SIDE

Gate

Wall or

Pillar

Summary of Contents for MGA600

Page 15: ...14 Transformer...

Page 20: ...19...

Page 21: ...20 left right NOTES...

Page 22: ...21 TIMER TO CLOSE T b w r t p TTC OFF MAXIMUM time 180 seconds...

Page 23: ...22 C840...

Page 25: ...24 CAUTION 240 VAC Transformer...

Page 27: ...26...

Page 28: ...27...

Page 29: ...28...