26

Input Voltage.....

230-240 VAC, 50 Hz

Max. Pull Force

800 N

Rated Load .......

8 Nm

Standby Power .

<1 W

Max. Door Mass..

130 kg

Max.Door Lift Under

Spring Tension....

15 kg

Max. Door Area..

18.0 m

2

Motor

Type ..................

DC gearmotor permanent

lubrication

Drive Mechanism

Drive .................

Belt with two-piece trolley on

steel rail.

Length of Travel

Adjustable to 3 m

Travel Rate .......

127-178 mm per second

Lamp.................

On when door starts, off 2-1/2

minutes after stop.

Door Linkage ....

Adjustable door arm. Pull cord

trolley release.

Safety

Personal ...........

Push button stop in

UP

and

DOWN

direction. Automatic

safety reverse and stop in UP

and reverse in DOWN

direction.

Electronic ..........

Automatic force adjustment

Electrical ...........

Transformer overload protector

and low voltage push button

wiring.

Limit Device ......

Optical RPM/Passpoint

detector.

Limit Adjustment

Electronic, Semi and Fully

Automatic.

Start Circuit.......

Low voltage push button circuit.

Dimensions

Length (Overall)

3.2 m for standard 2.3 m rail

Headroom Required

30 mm

Hanging Weight

14.5 kg

Receiver

Memory Registers

64

Operating Frequency

433.30/433.92/434.54 MHz

SPECIAL NOTE: Chamberlain strongly recommends

that The Protector System

TM

(IR Beams) be installed

on all garage door openers.

SPECIFICATIONS

MAINTENANCE SCHEDULE

Once a Month

• Manually operate door. If it is unbalanced or binding,

call a qualified door technician.

• Check to be sure door opens & closes fully. Adjust

limits and/or force if necessary, refer page 18.

• Repeat the safety reverse test. Make any necessary

adjustments..

Once a Year

• Lightly grease the belt, belt pulley and inside the rail

assembly where the trolley slides.

• Internally the opener does not require additional

lubrication.

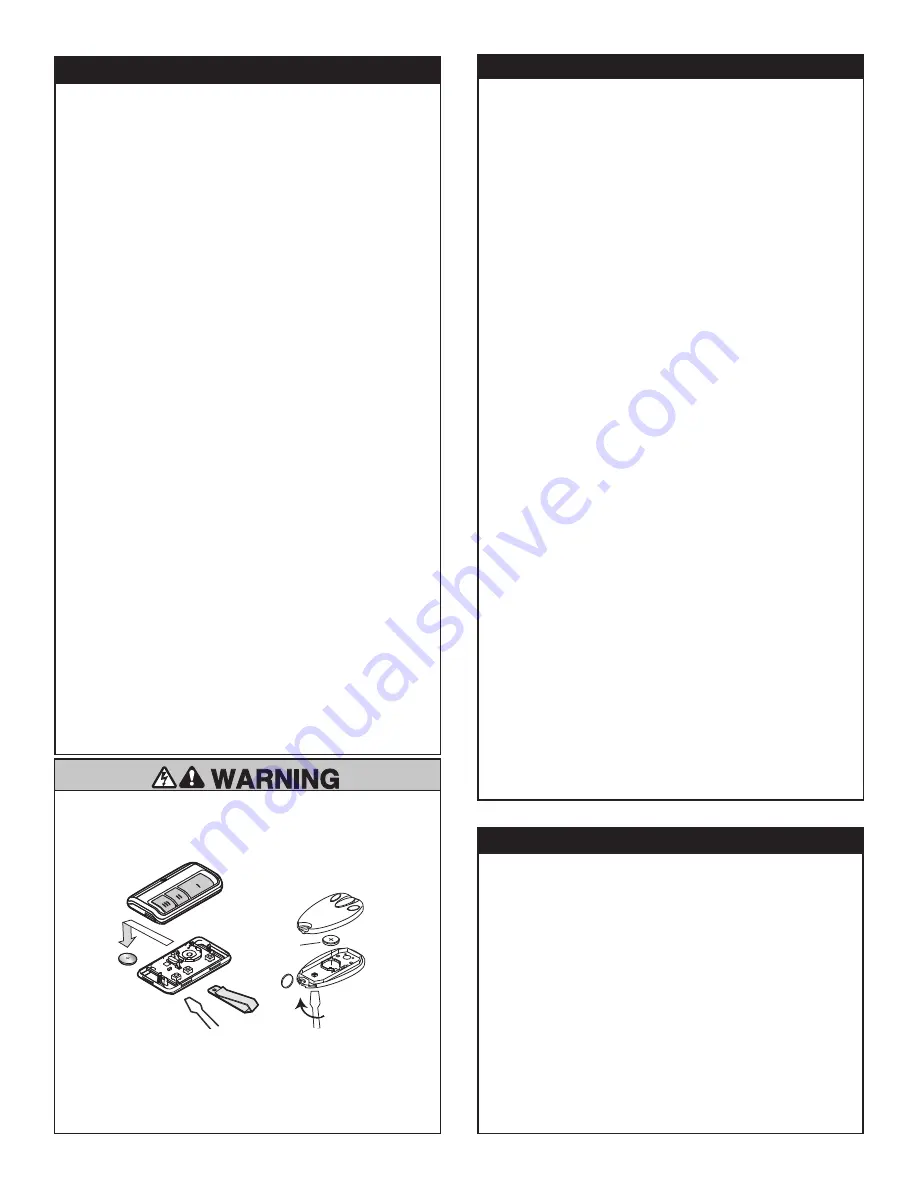

To prevent possible SERIOUS INJURY or DEATH:

• NEVER allow small children near batteries.

• If battery is swallowed, immediately notify doctor.

or

Carefully

Remove Battery

(CR2032 x 1)

THE REMOTE CONTROL BATTERY

To replace battery, use a screwdriver

blade to pry open the case as shown.

Insert battery positive side up.

Dispose of old battery properly.

Your opener can be activated by any of the following devices:

• Open control panel: Up and Down Buttons.

• The Outside Keyswitch or Keyless Entry System (if you

have installed either of these accessories).

• The Remote Control Transmitter. Hold the push button

down until the door starts to move.

Opening the Door Manually: Door should be fully closed if

possible. Weak or broken springs could allow an open

door to fall rapidly. Property damage or serious personal

injury could result.

The door can be opened manually by pulling the release

handle down. To reconnect the door, pull the release handle

down and toward the opener.

Do not use the manual release handle to pull the door

open or closed. When the Opener is Activated by Remote

Control:

1. If open, the door will close. If closed, the door will open.

2. If closing, the door will stop.

3. If opening, the door will stop (allowing space for entry and

exit of pets and for fresh air).

4. If the door has been stopped in a partially open or closed

position, it will reverse direction.

5. If an obstruction is encountered while closing, the door will

reverse.

6. If an obstruction is encountered while opening, the door will

reverse and stop.

7. The optional Protector System™ uses an invisible beam

which, when broken by an obstruction, causes a closing

door to open and prevents an open door from closing. It is

STRONGLY RECOMMENDED for homeowners with young

children.

The opener lights will turn on under the following conditions:

when the opener is initially plugged in; when power is restored

after interruption; when the opener is activated or when the IR

Beams are triggered with the door in the Open position.

They will turn off automatically after 2-1/2 minutes or provide

constant light when the Light feature on the LCD Motion

Detecting Control is activated. Bulb size is E27. Bulb power is

40 watts maximum.

USING YOUR GARAGE DOOR OPENER

CARE OF YOUR OPENER

Summary of Contents for MT3850EVO

Page 2: ...0...