2 - MACHINE TECHNICAL INFORMATION

2 - 28

SERIAL NUMBER OF THE MACHINE

CHASSIS NUMBER

The chassis number of your machine is printed on the front right side of the

chassis, and coated with a layer of black paint. When requesting assistance or

spare parts, please provide Merlo Technical Support Service with both the

chassis number and the Sav number of your machine.

This code is made up of 17 characters, divided into 3 sectors, and shows the

manufacturing data of your machine.

An example of a chassis number stamped on a chassis is given below:

• chassis identification code: ZF1A28L01C1190883

ZF1: code that identifies MERLO S.p.A.

A28L01: specific model code

C1190883: code that identifies the manufacturing decade (C= 2010-2019), the manufacturing year (1=2011), the

manufacturing progressive number (1908), and the engine code (83)

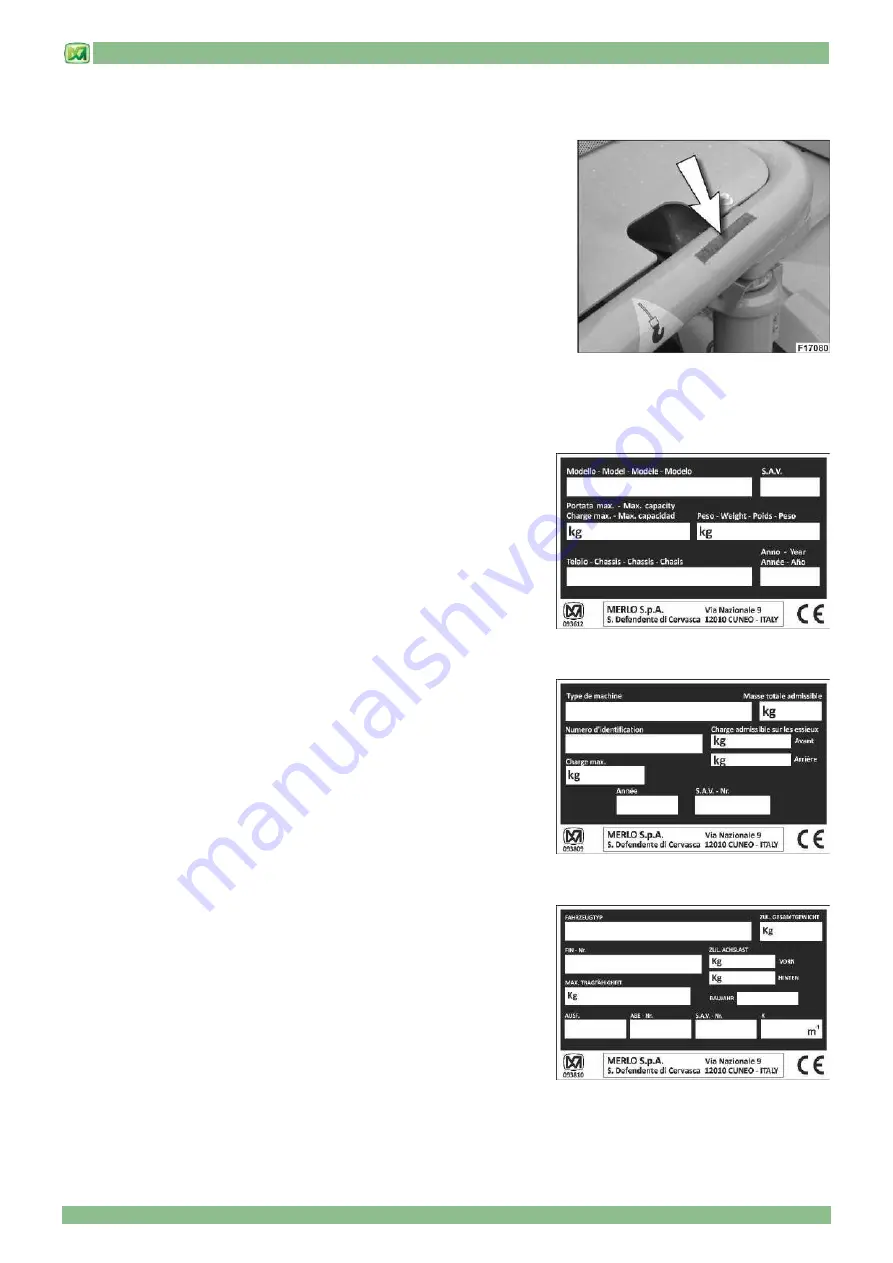

IDENTIFICATION AND TYPE APPROVAL PLATES

• MACHINE IDENTIFICATION PLATE

The machine identification plate is placed in the rear left part of the cab and

provides the operator with the following data:

- Model

- SAV number

- Maximum capacity

- Weight

- Chassis number

- Manufacturing year

• MACHINE IDENTIFICATION PLATE (SWISS MARKET)

The machine identification plate is placed in the rear left part of the cab and

provides the operator with the following data:

- Model

- Total permissible mass

- Chassis number

- Maximum permissible load per axle (front and rear)

- Maximum load

- Manufacturing year

- SAV number

• MACHINE IDENTIFICATION PLATE (GERMAN MARKET)

The machine's identification plate is applied in the engine compartment and

provides the operator with the following information:

- German homologation certificate (ABE)

- Total weight of the machine

- Chassis number

- Weight on front and rear axle

- Capacity of the machine

- Manufacturing year

- ABE version

- ABE homologation number

- SAV number of the machine

- Total unladen mass of the machine

Summary of Contents for PANORAMIC

Page 20: ...2 MACHINE TECHNICAL INFORMATION 2 9 only for models P60 10EE P72 10EE...

Page 27: ...2 MACHINE TECHNICAL INFORMATION 2 16 DIMENSIONS P37 12 PLUS DIMENSIONS P38 12 PLUS P38 12...

Page 30: ...2 MACHINE TECHNICAL INFORMATION 2 19 DIMENSIONS P60 10 P60 10EE DIMENSIONS P72 10 P72 10EE...

Page 35: ...2 MACHINE TECHNICAL INFORMATION 2 24 LIFTING A LOAD...

Page 44: ...3 STICKERS WITH CONTROL DESCRIPTIONS LEAFLETS IN THE CAB 3 3 only for models P60 10EE P72 10EE...

Page 49: ...3 STICKERS WITH CONTROL DESCRIPTIONS LEAFLETS IN THE CAB 3 8...

Page 51: ...3 STICKERS WITH CONTROL DESCRIPTIONS LEAFLETS IN THE CAB 3 10...

Page 52: ...3 STICKERS WITH CONTROL DESCRIPTIONS LEAFLETS IN THE CAB 3 11 P37 12 PLUS P40 9 PLUS...

Page 53: ...3 STICKERS WITH CONTROL DESCRIPTIONS LEAFLETS IN THE CAB 3 12...

Page 54: ...3 STICKERS WITH CONTROL DESCRIPTIONS LEAFLETS IN THE CAB 3 13 P60 10 P72 10 P60 10EE P72 10EE...

Page 55: ...3 STICKERS WITH CONTROL DESCRIPTIONS LEAFLETS IN THE CAB 3 14 END OF SECTION...

Page 138: ......

Page 185: ......

Page 197: ...10 ELECTRICAL SYSTEM 10 1 CONTENTS GENERAL FEATURES 2 BATTERY 2 FUSES 3 END OF SECTION 4...