Merloni Elettrodomestici

55 CM WIDE BUILT-IN FRIDGE-FREEZERS

Technical Manual

I

04-10-22/01

9-33

Language

Issue/Edition

Page

3. Solenoid valve

INFORMATION:

Solenoid valve (EV) operation is linked to demand for refrigeration from the two com-

partments (FR and FZ).

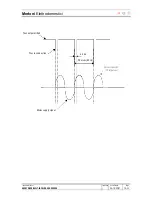

The component is driven by a series of electrical impulses and, once forced into posi-

tion, is able to maintain that position without the need for any further energy. The elec-

trical impulses are simply supply voltage half-waves specially selected by the control

board: (by means of special circuitry on the board: triac) positive half-waves force the

component in one direction and negative half-waves force it the opposite way. The link

between the condition of the solenoid valve and the appliance's thermodynamic circuits

(FR or FZ) depends on the connection of the driver cable and the capillary coupling.

The control board sends first of all a sequence of 10 impulses to force the solenoid

valve into the opposite state to that which is necessary and, after a few seconds (2-3s),

sends another 10 impulses to force the solenoid valve into the desired state. The pur-

pose of this is to move the internal stop and thus ensure, during the exchange, the re-

moval of any impurities.

To ensure that no interference has altered the state of the solenoid valve (which is sen-

sitive to electrical interference) and that it is in the desired condition, it is automatically

refreshed every 15 minutes.

The fridge nonetheless always has priority over the freezer.

POSSIBLE CAUSE OF MALFUNCTION:

Microprocessor management

Solenoid valve driver circuit on the board

Connection on the board

Wiring

Connections on the solenoid valve

Solenoid valve

TESTING:

General on the appliance

: direct cold air into the freezer compartment only by

switching on the appliance and turning the fridge knob to zero. Check that only the

freezer compartment is cold. Subsequently, turn the fridge knob to switch on both

compartments. Check that cold air is directed into the refrigerator compartment.

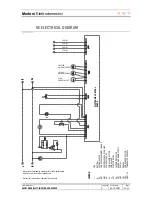

Wiring

: check for continuity and short circuits; check the connections (connectors and

terminals); check for presence of voltage.

Component

: check with simulated load (lamp); direct check of the solenoid valve.

Electronic board

: visual check and quick check of the board (blowouts or burnouts,

etc.); check by using a replacement.