14

MERRY TILLER SERVICE BULLETIN

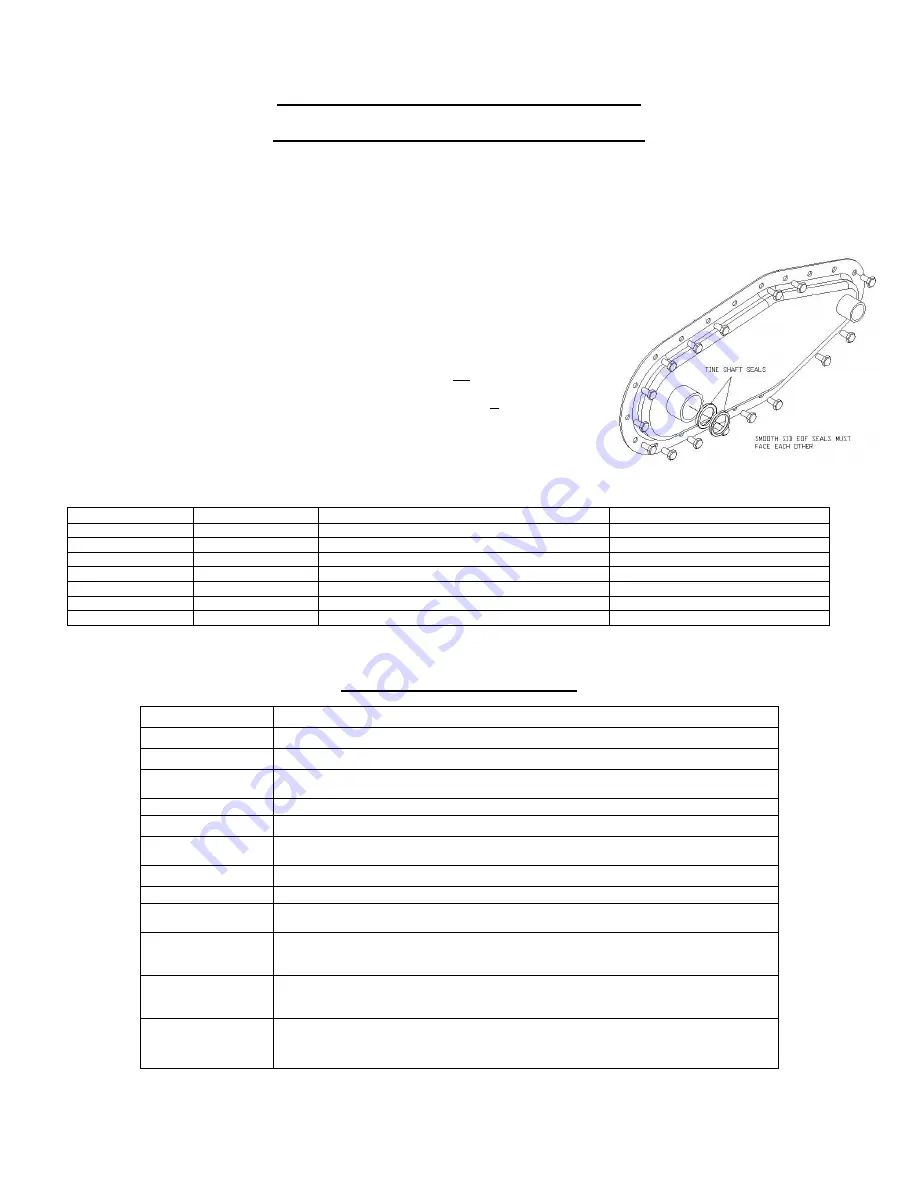

TIME TO CHANGE THE TINE SHAFT SEALS

Tine Shaft Seal Replacement Instructions

It is extremely important that the oil seals on the tiller transmission be inspected and replaced regularly to ensure proper lubrication and to

prevent dirt from entering the transmission. Both sides of the tine shaft have two oil seals. These seals are inserted back to back over the tine

shaft. The inner seal faces into the transmission and is designed to keep lubricant from escaping from the transmission. The outer seal faces

outward and is

designed to keep dirt out of the transmission. The Merry Tiller transmission is lubricated with heavy “00” grease. If the seals

fail, it may not be noticed due to the heavy consistency of the grease. This is the best possible

lubricant available and will add years of life to your Merry Tiller. Seals should be inspected

regularly and replaced as needed or before periods of expected extended use.

To replace the seals proceed as follows.

1.

Take a screwdriver or awl and hammer along the tine shaft until you can pry the first

seal out.

2.

Repeat and take the second seal out.

3.

Place the new seal on the tine shaft with smooth side facing out, and press into place.

(Note: A 1 ½” ID piece of plastic pipe works great to do this).

4.

Place the second seal on the tine shaft with the smooth side facing in, and press into

place.

5.

Repeat to other side of the transmission.

Note: It is very important that the smooth side of the two seals be against each other.

Replacement Parts

PART #

QTY

WHERE USED

DESCRIPTION

708-3241

1

MINNIE

OIL SEAL

708-3241-10

10

MINNIE

OIL SEAL

– 10 PACK

708-3241-50

50

MINNIE

OIL SEAL

– 50 PACK

706-0344

1

SUBURBAN/INTERNATIONAL

OIL SEAL

706-0344-10

10

SUBURBAN/INTERNATIONAL

OIL SEAL

– 10 PACK

706-0344-50

50

SUBURBAN/INTERNATIONAL

OIL SEAL

– 50 PACK

MAINTENANCE SCHEDULE

Frequency

Service required

After every use

Inspect belts & pulleys for proper alignment and excessive wear

Check operation of belt and idler, make sure tines stop & start correctly

Inspect transmission for any leakage, check all bolts for tightness. Pay particular attention to

center bolt that secures the transmission to the frame rails

Check tines for wear and excessive play, make sure no pins are missing

Perform normal engine maintenance

Every 150 hours

Inspect transmission case assembly, conduct test for excessive travel, (see attached). Check

for excessive wear on case halves

Check tine shaft and drive shaft for up and down play, if loose replace bearings.

If transmission is OK replace tine shaft and drive shaft seals

Inspect tines for wear, if cutting corner is rounded replace tines. Check pin holes for

elongating and wear, make sure no pins are missing

Anytime the transmission is unbolted from the frame rails it is necessary to secure the internal

sprockets with a 5/16" rod cut to the same width of the transmission case. It is possible for

the internal sprockets to move if not secured during service

Every 600 hours

Remove transmission for internal inspection. Disassemble and inspect all parts for wear.

Clean all parts, replace worn parts as needed, relubricate with approx. 9 oz.“00” grease.

Reassemble with new case gasket and reinstall on tiller.

Anytime the transmission is unbolted from the frame rails it is necessary to secure the internal

sprockets with a 5/16" rod cut to the same width of the transmission case. It is possible for

the internal sprockets to move if not secured during service