BA2070/03/16

Messko

13

2

Product specification

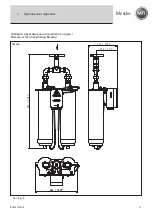

The dehydrating breather can be mounted either on the pipe of

the oil conservator with a flange (Fig. 1/1) as standard or with

2 side mounting rods (appendix, Fig. 7) as an option.

2 .1 Function specification

Dehydrating breathers work according to the following principle.

When the oil conservator suctions in air (e.g., due to the reduced

load), the air flows through a filter made of high-grade steel

wire mesh (Fig. 1/4) to the inside of the device. This filter and

the dust cap (Fig. 1/5) filter dust, sand and other dirt particles

from the air. The filtered air flows through the desiccant cham-

ber (Fig. 1/8) filled with colorless, moisture adsorbing pellets

and is dehydrated. The dehydrated air rises further via the pipe

in the oil conservator.

A sensor (Fig. 1/10) monitors the air flowing by to determine the

saturation degree of the desiccant. Depending on its state, the

desiccant is regenerated with the heating elements integrated

in the desiccant container. A temperature sensor monitors the

function of the heating elements.

The water vapor created by the baking process condenses by

convection in the dehydrating breather on the bottom metal

flange (Fig. 1/7). The condensed water exits the device through

the high-grade steel filter.

No maintenance is required for replacement and regeneration

of the desiccant.

2 .2 Twin Dehydrating Breather

The twin dehydrating breather (DB 200 D-T) uses the same

principle as the „single“ dehydrating breather. This is equipped

with two parallel desiccant containers to enable them to

handle the air exchange of greater amounts of oil.

2 .3 Desiccant

Colorless, non-poisonous, moisture-adsorbing Silicagel pellets

which do not change their color when a moisture saturati-

on occurs are used as desiccant material in the dehydrating

breather. Silicagel pellets which do change their color have a

limited lifetime due to the chemical additives used.

2 .4 Control of the heater

The following 3 types are available for controlling the heater.

α

-controller: Recommended for use on tap changers, arc su-

pression coils and traction transformers. Here the dehydrating

breather is baked out based on its state which is monitored for

humidity.

β

-controller: A self-learning system that is recommended for

use on transformers with cyclic loads (see applications, table

2). In addition to monitoring the humidity, a time window is

determined here during which the oil conservator exhales and

the dehumidification chambers are regenerated.

γ

-controller:

Recommended for special applications such as

transformers installed in caverns, furnace transformers and GSU

machine transformers with non-periodic breathing behavior. If

the moisture content of the air flowing in the direction of the

transformer exceeds a specified value, the silica gel chambers

are regenerated alternately.

For redundancy, a time control is also present which starts the

regeneration of the desiccant at predetermined intervals should

the moisture sensor fail.

The control unit and the terminals for the electrical connec-

tions are located in the terminal box (Fig. 1/9).

Table 2 lists the recommended application areas for the

different MTraB versions .

2 .5 Self-monitoring function

The dehydrating breather has a self-monitoring function. When

the device malfunctions, this is reported by a relay contact. The

following malfunctions are detected:

- Failure of the power voltage

- Failure of the silicon gel heater

- Failure of a sensor

- Internal error

- Failure of the ball valve (

only with the

γ

-controller)

2 .6 Outputs

Analog output:

Temperature in the pipe -40 to +80 °C;

Signal 4 to 20 mA standard, others optional;

2

Product specification

1

2

3

4

5

6

7

8

9

10

11

12

Fig .

1

Summary of Contents for MTraB DB100

Page 2: ...BA2070 03 16 2 ...

Page 23: ...BA2070 03 16 Messko 23 ...