BA2070/03/16

14

Error signal < 3.6 mA standard, when temperature sensor fails

Relay outputs:

1 x change-over contact, signaling relay for regeneration

active/inactive

1 x normally closed contact, signaling relay for device faults

(failsafe)

2 .7 Filterheater (HT version)

We recommend the HT version, which features a heated high-

grade steel filter (Fig. 1/4) to ensure device functionality at

lowest temperatures, for applications in cold or arctic climates

(ambient temperature is continuously below -5°C over a period

of 20 days).

2 .8 Status indicators

Three LEDs are installed on the side of the terminal box and 2

LEDs are installed on the board in the terminal box to indicate

the status of the device.

If an error occurs on the device, it is signaled by differently lit

or flashing LEDs (see chapter 5.4, table 1).

3 Installation

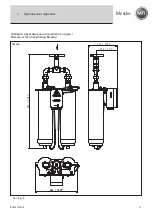

Depending on the particular application, the dehydrating

breather is mounted on the pipe to the oil conservator. A

suitable counter-flange must be installed on the pipe to mount

the dehydrating breather. Three connection types are listed

in the appendix (Fig. 4 to 6). During mounting, it is extremely

important to ensure that the included seal is installed between

the flanges. The DIN flange is secured with the 3 M12 screws

included. First, slightly tighten each of the screws in succession.

Then tighten these screws with a torque of 80 Nm. Wait

5 minutes and then tighten again to 80 Nm. The device is

available as an option with 2 side mounting rods. When equip-

ped with these rods, the device conforms to the installation

height h as per DIN 42 562.

In case of any further questions concerning the counter flange

or any customer-specific flanges, please do not hesitate to

contact us.

After mounting, the device can be aligned with a double scre-

wed fitting. To do this, loosen the nut (Fig. 1/2) and turn the

device to the desired position. Then tighten the nut again.

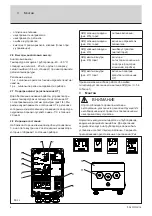

LED, green, outside (Fig.2/5) on

Power voltage on

LED, yellow, outside (Fig.2/4) on

Regeneration process active

LED, red, outside (Fig.2/3)

Device error (flashing/on)

LED, yellow, inside (Fig.2/6) on

Anti-condensation heater on

(heater of the terminal box)

LED, yellow, inside (Fig.2/7) on

Filter heater on (HT version)

5

4

3

6

7

8

10

9

11

2

1

Fig. 2

CAUTION

The operating and installation requirements described in this

manual must be strictly complied with. If not, the device

may be damaged or may malfunction.

CAUTION

Do not unscrew the nut (Fig.1/12), since you may damage

the sealing of the device.

3

Installation

Summary of Contents for MTraB DB100

Page 2: ...BA2070 03 16 2 ...

Page 23: ...BA2070 03 16 Messko 23 ...