BA2070/03/16

Messko

15

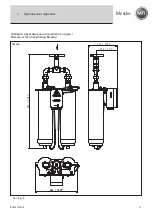

The twin dehydrating breather is mounted like the „single“

dehydrating breather. Do not forget the larger dimensions of

the twin dehydrating breather (Fig. 8) when you are planning

installation.

4 Electrical connection

To wire the hydrating breather, open the terminal box (Fig. 1/9).

The cover of the terminal box (Fig. 2/10) is grounded with a

contact lead (Fig. 2/9) and is thus protected against falling to

the ground.

The wiring is done with cable glands (Fig. 2/11) M20 x 1.5 or

through a 1/2“ - 14NPT coupling. Remove the cable sheaths

accordingly and strip the insulation to a length of 7 mm (1/4“).

4 .1 Power voltage

Connect the voltage supply (as per the nameplate) to terminals

2 (L) and 3 (N) and the protective conductor to 1 (PE). The

voltage supply should be protected with a 16A automatic

circuit breaker.

For the device version with

γ

controller (DB200G), the voltage is

supplied via the 2(L) and 3(N) connection terminals in the housing

cover of the terminal box (see appendix Fig. 9).

4 .2 Relay

The error relay (normally closed contact; failsafe) is connected

to terminals 4 and 5. When a device error occurs or the voltage

supply is not connected or not switched on, the contact closes.

The error relay falls after a time-delay (> 7 seconds) before the

voltage supply is switched off so that brief interruptions of the

voltage supply do not generate an error message.

The signaling contact for the regeneration procedure (change-

over contact) is connected to terminals 6, 7 and 8. When the

desiccant is regenerated, contact between terminals 7 and 8

is made.

4 .3 Analog output

The analog output is connected to terminal 9(+) and 10(-).

We recommend using a shielded cable for the connection and

connecting the shield to terminal 11.

4 .4 Device grounding

The device can be grounded with the M12 grounding screw

(Fig. 1/10). When potential differences are to be expected bet-

ween ground and the protective conductor (PE), the grounding

connection should not be used. An insulated device model is

available as an option. Contact Messko for further information.

5 Operation and maintenance

5 .1 Device self test

After installation and connection, the dehydrating breather

is ready for operation. Upon connection of the power supply

the device automatically performs a device self test (approx.

15 sec.). During the entire self test, the LEDs located outside

flash in succession while the function of the relays (except the

error relay) and the sensors is being checked. After a self-test

the device switches to the standard control software which will

be indicated by the green LED. When an error is detected, this

is indicated (see chapter 5.4 Fault monitoring). An expanded

device self test can be started with the test button which is

available as an option (see chapter 5.2).

5 .2 Test button (optional)

The test button which is available as an option can be used to

check the following functions:

- Internal functions such as during switch on (device self test)

- SiO2 heater.

Errors are indicated as specified in table 1.

The function test takes approx. 5 minutes. Afterwards, if opera-

tion is free of errors, the device returns to its normal routine.

5 .3 Maintenance

During regular checks of the transformer, we recommend per-

forming the following checks on the dehydrating breather:

• Check the exterior condition of the device for dirt and

damage (especially the dust cap and the high-grade steel

filter).

4

Electrical connection

5

Operation and maintenance

WARNING

Hazardous electrical voltages!

It is imperative to deactivate the power supply before

opening the terminal box and during wiring of the device.

CAUTION

Electrical connections may only be carried out by qualified,

skilled personnel trained in the applicable safety regulations

of the relevant country.

CAUTION

Do not connect terminal 2a (L‘)! It must only be connected

when an optional adapter transformer is used.

NOTE

After a regeneration procedure, the SiO2 heater cannot

be checked again for the next 8 hours. If the test button

is pressed during this time, the outside LEDs flash 10 times

and a reduced test is initiated without the SiO2 heater

check.

Summary of Contents for MTraB DB100

Page 2: ...BA2070 03 16 2 ...

Page 23: ...BA2070 03 16 Messko 23 ...