Form 43343350

-36-

Dec 2017

GAS PRESSURE TABLE

GAS TYPE

MANIFOLD PRESSURE

High Low (2-stage only)

SUPPLY PRESSURE

Minimum*

Maximum

Natural Gas

3.5” W.C.

1.4” W.C.

5” W.C.

1

14” W.C.

Propane Gas

10.0” W.C.

4.0” W.C.

11” W.C.

2

14” W.C.

* Minimum permissible gas supply pressure for purpose of input adjustment.

1

7” W.C. for Models 150-200

2

12” W.C. for Model 200

15.0)

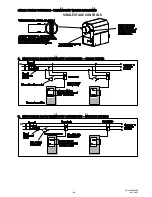

ELECTRICAL THERMOSTAT CONNECTIONS

1.

All electric wiring shall conform to the latest edition of the National Electrical Code (ANSI/NFPA No. 70), or

the code legally authorized in the locality where the installation is made.

2.

The unit must be electrically grounded in accordance with the National Electrical Code (ANSI/NFPA No.

70-latest edition). In Canada, refer to current standard C22.1 Canadian Electrical Code Part 1.

3.

The wiring providing power to the heater shall be connected to a permanently live electrical circuit, one that

is not controlled by a light switch.

4.

The power supply to the unit should be protected with a fused disconnect switch or circuit breaker. A service

switch, as required by local codes, shall be located in the vicinity of the heater (check local codes for

allowable distances) and should be identified as Heater Service Switch. All electrical wiring must be located

in accordance with the required Clearances to Combustibles from the heater as listed on the nameplate on

the heater.

5.

Connection to the power supply is provided by an 18/3 gauge x 72” long cord with grounded 3 prong plug.

6.

The post purge function of the burner (fan on for 30 seconds after the call for heat) will only be enabled

when using a 24 Volt thermostat. With the line Voltage thermostat post purge operation is disabled.

7.

If any of the original wire as supplied with the appliance must be replaced, it must be replaced with wiring

material having a temperature rating of at least 105ºC. (18 Ga. CSA 600V Type TEW)

8.

When connecting the supply circuit to the heater, wiring material having a minimum size of 14 AWG and a

temperature rating of at least 90ºC shall be used.

Summary of Contents for 44488010

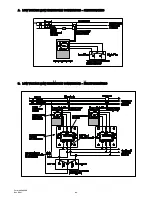

Page 15: ...Form 43343350 14 Dec 2017 7 1 TYPICAL ASSEMBLY LAYOUT STRAIGHT SERIES SHOWN ...

Page 16: ...Form 43343350 Dec 2017 15 8 0 DIMENSIONS STRAIGHT SERIES Typical Dimensions Up to 60 Ft Shown ...

Page 17: ...Form 43343350 16 Dec 2017 8 1 DIMENSIONS U SERIES Typical Dimensions Up to 50 Ft Shown ...

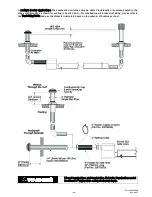

Page 18: ...Form 43343350 Dec 2017 17 8 2 HEATER ASSEMBLY JOINING OF TUBE SECTIONS ...

Page 19: ...Form 43343350 18 Dec 2017 ...

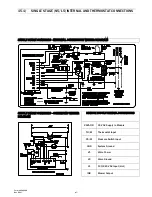

Page 52: ...Form 43343350 Dec 2017 51 20 0 CONTROL COMPONENT LOCATION ...

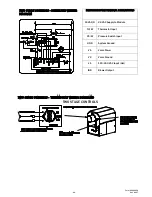

Page 54: ...Form 43343350 Dec 2017 53 22 0 TROUBLESHOOTING GUIDE SINGLE STAGE N1 L1 ...

Page 55: ...Form 43343350 54 Dec 2017 TROUBLESHOOTING GUIDE SINGLE STAGE CONTINUED ...

Page 56: ...Form 43343350 Dec 2017 55 TROUBLESHOOTING GUIDE SINGLE STAGE CONTINUED ...

Page 57: ...Form 43343350 56 Dec 2017 22 1 TROUBLESHOOTING GUIDE TWO STAGE N2 L2 ...

Page 58: ...Form 43343350 Dec 2017 57 TROUBLESHOOTING GUIDE TWO STAGE CONTINUED ...

Page 59: ...Form 43343350 58 Dec 2017 TROUBLESHOOTING GUIDE TWO STAGE CONTINUED ...

Page 66: ...Form 43343350 Dec 2017 65 ...