18

Fault

Cause

Remedy

No pressure builds up in

the device.

The pump is not screwed

on tightly.

Screw the pump on tightly.

O-ring [13] on the pump is

faulty.

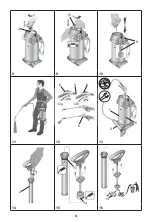

)LJ

Replace the O-ring.

Diaphragm [14] is defecti-

ve.

(Fig. 16)

Replace the diaphragm.

/LTXLGÀRZVRXWRIWKH

pump.

Valve disc [15] dirty or

defective.

(Fig. 17)

Clean or replace the valve disc.

Piston pressure gauge

does not indicate any tank

pressure.

6DIHW\YDOYHEORZVRႇWRR

early.

Piston pressure gauge [16]

is defective.

(Fig. 18)

Replace the piston pressure

gauge.

The nozzle does not spray

even though pressure is

present.

Nozzle [17]

(Fig. 19)

or /

DQG¿OWHU>@

Fig. 20)

is

clogged.

&OHDQWKH¿OWHURUDQGQR]]OH

7KHVKXWRႇYDOYHGRHVQRW

close.

Liquid emerges without the

lever being activated.

O-rings [23] of the pressu-

re bolt [24] are not grea-

sed / lubricated.

(Fig. 22)

Faulty O-rings [23] or pres-

sure bolt [24].

(Fig. 22)

Grease the O-rings of the

pressure bolt (dismantle shut-

RႇYDOYH

ĺVHFWLRQÄ&DUHDQG

PDLQWHQDQFH³

Replace O-ring or pressure bolt.

EN ENGLISH

Faults

&RQWDFWDGGUHVVIRUDGGLWLRQDOLQIRUPDWLRQĺVHHWLWOHSDJH

Use only original spare and accessory parts.

6993140_CLEANER_PROFIPLUS_15Spr.indd 18

06.11.2020 10:08:57

Summary of Contents for 3270TP

Page 4: ...8 9 10 11 12 13 14 15 16 4 2 10 8 6 12a 12b 5 5 1 2 2 13 14 14 6 6...

Page 5: ...17 18 19 20 21 22 5 2 15 16 17 27 6 18 19 19 20 21 22 25 23 24...

Page 104: ...104 33 33 3 3 3 3 5...

Page 105: ...105 5...

Page 107: ...107 1 5 bar 0 49 l min 2 0 bar 0 56 l min 3 0 bar 0 69 l min 5 EDU D 2...

Page 108: ...108 D E F 5 EDU...

Page 109: ...109 5...

Page 111: ...111...

Page 112: ...112...