16

Care and maintenance

Faults

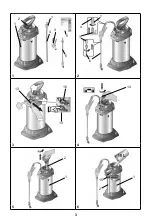

After using the device 50 times or at least once a year:

• Disassemble the pump [2] and grease the diaphragm [20].

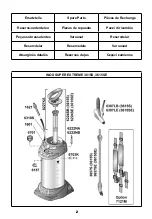

(Fig. 12 - 13)

• Clean the nozzle [21] under running water.

(Fig. 14)

• Remove the filter [22] from the shut-off valve [3] and clean it under flowing water

(Fig. 15)

• Grease the O-rings [19] and [24]

(Fig. 13 and/or 19)

Observe the instructions in the section entitled „Safety“.

Use only spare parts and accessories from MESTO (Fig. on page 2)

Observe the legal requirements of your country for accident prevention and

check the device in regular intervals. If there are no special rules, we recom-

mend you have the device examined externally by a competent professional

every 2 years and subject it to an internal inspection every 5 years. We would be

happy to provide you with an inspection schedule in German or English.

Fault

Cause

Remedy

No pressure builds up in

the device

The pump is not screwed

on tightly.

Screw the pump on tightly

O-ring [19] on the pump is

faulty.

Replace the O-ring.

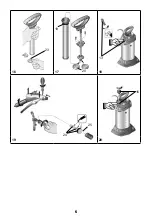

(Fig. 17)

Diaphragm [20] is defective. Replace the diaphragm.

(Fig. 17)

Liquid flows out of the

pump.

Valve disc [23] dirty of

defective.

Clean or replace the valve disc.

(Fig. 16)

The nozzle does not

spray even though pres-

sure is present.

Filter [22] and / or nozzle

[21] blocked.

Clean the filter or / and nozzle.

(Fig. 14 + 15)

.

Safety valves blow off

too early.

Safety valve [13] is defec-

tive.

Replace safety valve.

(Fig. 18)

The shut-off valve does

not close.

Liquid emerges without

the lever being activa-

ted.

O-rings [24] on the pressure

bolt not greased.

Defective pressure bolt [25]

or O-rings [24]

Grease the O-ring of the pres-

sure bolt.

(Fig. 19)

Replace the pressure bolt or

O-ring.

(Fig. 19)

Pressure gauge is not

indicating any tank

pressure

Manometer [16] defekt.

Pressure gauge [16] defective.

Unscrew pressure gauge [16]

and replace. (Fig. 20)

Contact address for additional information

→ Title page.

GB

IRL

AUS

USA

NZ

CDN

IND