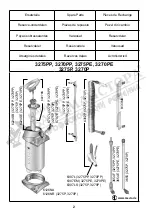

16

1. Pull up the red button on the piston pressure gauge [8] until all excess pressure is

released from the tank.

(Fig. 3)

2. Press the piston rod with handle [10] down and turn it counterclockwise.

Ź7KHSLVWRQURGZLWKKDQGOHLVORFNHG

)LJ

3. Unscrew the pump [2] from the tank.

(Fig. 6)

Spraying pressure

6SUD\LQJUDWHZLWKÀDWMHWQR]]OHRULJLQDOHTXLSPHQW

1.5 bar (21.8 psi)

0.49 l/min

2.0 bar (29.0 psi)

0.56 l/min

3.0 bar (43.5 psi)

0.69 l/min

EN ENGLISH

Preparation

+

:HUHFRPPHQG\RXPL[WKHVSUD\LQJOLTXLGLQWKHGHYLFHRUSUHPL[LWLQDQH[WHUQDOWDQN

)LOOWRZLWKZDWHUSRXULQWKHVSUD\LQJDJHQWDQGWKHQDGGPRUHZDWHUXQWLOIXOO

4. Add the spraying liquid to the tank [1].

(Fig. 7)

&KHFNWKH¿OOLQJOHYHOZLWKWKHVFDOH>@RQWKHWDQN

(Fig. 7)

6. Screw the pump [2] into the tank.

(Fig. 8)

7. Press the piston rod with handle [10] down and turn it counterclockwise.

Ź7KHSLVWRQURGZLWKKDQGOHLVXQORFNHG

(Fig. 9)

8. Generate the desired pressure

ĺ7DEOH

in tank

(Fig. 10).

+

7KHPD[LPXPSUHVVXUHVKRXOGQRWH[FHHGEDUUHGOLQHRQWKHSLVWRQSUHVVXUH

JDXJH)LJ,IWKHPD[LPXPSUHVVXUHLVH[FHHGHGWKHVDIHW\YDOYHZLOOHQJDJH

DQGUHOHDVHWKHH[FHVVSUHVVXUH

9. Press the piston rod with handle [10] down and turn it counterclockwise.

)LJ

Ź7KHSLVWRQURGZLWKKDQGOHLVORFNHG

Spraying

+

7RSUHYHQWGULSSLQJKROGWKHVSUD\ZDQGXSZKHQ¿UVWVSUD\LQJDQGDFWLYDWHWKH

VKXWR௺YDOYHXQWLOQRPRUHOLTXLGPL[HGZLWKDLULVHPHUJLQJIURPWKHQR]]OH

,IUHTXLUHGUHVHWWKHZKHHOORFN>D@DQGDFWLYDWHWKHVKXWRႇYDOYH>@

(Fig. 12)

Ź6SUD\LQJPD\QRZEHJLQ

3. Make certain the optimum spraying pressure is set

ĺ7DEOH

) on the piston pressure

gauge [8]

(Fig. 10)

.

7DEOH'HSHQGHQFH6SUD\LQJUDWH±VSUD\LQJSUHVVXUH

4. If the spraying pressure decreases more than 0.5 bar

(7.3 psi)

from the optimum level,

pump some more.

+

,IOLTXLGPL[HGZLWKDLUHPHUJHVIURPWKHQR]]OHWKHWDQNLVHPSW\

Observe the instructions in the section entitled „Safety“.

The device must be in an upright position.

,I¿OOLQJWKHWDQNIURPDZDWHUOLQHHQVXUHWKDWWKHOLQHRUDKRVHGRHVQRWSURMHFW

into the tank.

Observe the instructions in the section entitled “Safety”.

Operate the device only while it is vertical or suspended upright and nearly vertical.

Avoid allowing drops of spray to drift onto areas that are not being treated.

Observe the instructions of the spray product manufacturer!

1. Hang the device over your shoulder.

(Fig. 11)