18

ENGLISH

vide adequate protection against contact

with the band saw blade, it must always

be set as close as possible against the

work piece (distance 3 mm max.).

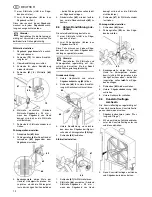

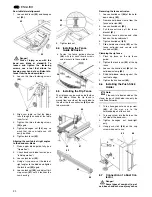

Lower blade guard

The lower blade guard

(35)

protects

against inadvertent contact with the

band saw blade below the saw table.

The lower blade guard must be installed

during operation.

Housing doors

The housing doors

(36)

protect against

contact with the rotating parts inside the

machine.

The housing doors are equipped with

interlocking contacts. These turn the

motor OFF when one housing door is

opened while the saw is running.

The housing doors must be closed while

the machine is in use.

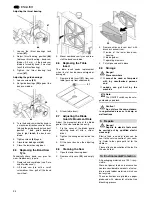

Push stick

The push stick serves as an extension of

the hand and protects against accidental

contact with the saw blade.

The push stick must always be used if

the distance between band saw blade

and a rip fence is less than 120 mm.

Guide the push stick at an angle of 20

q

… 30

q

against the saw table's surface.

When the push stick is not used it can be

stored on the push stick holder provided

at the band saw frame.

Replace push stick if damaged.

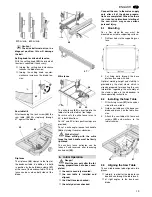

x

Set upper blade guide to its lowest

position.

x

Remove projecting accessories.

x

When shipping, use original packing

if possible.

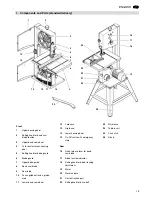

3

Note:

In this chapter the essential oper-

ating elements of the machine are intro-

duced.

The proper use of the machine is

described in chapter "Operation". Read

this chapter before using the saw for the

first time.

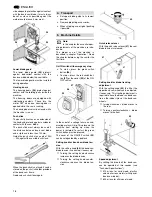

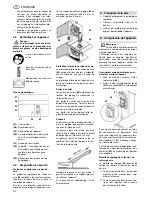

On/Off switch with emergency stop

x

To start = press the green switch

button

(38)

.

x

To stop = press the red switch but-

ton

(37)

or the cover

(39)

of the ON/

OFF switch.

In the event of a voltage failure an und-

ervoltage relay will trip. This prevents the

machine from starting up when the

power is restored. To restart, the green

switch button must be pressed.

The cover of the ON/OFF switch

(39)

can be safeguarded by a padlock.

Setting knob for band saw blade ten-

sion

With the setting knob

(40)

the band saw

blade tension is corrected, if necessary:

Turning the setting knob clockwise

increases the blade tension.

Turning the setting knob counter-

clockwise reduces the blade ten-

sion.

Quick release lever

With the quick release lever

(41)

the saw

blade tension is released.

Setting knob for blade tracking

adjustment

With the setting knob

(42)

the tilt of the

upper band saw wheel can be adjusted,

if necessary. This tracking adjustment is

required to have the blade run dead cen-

tre on the rubber tyres of the band saw

wheels:

turning clockwise = blade moves to

the rear

Turning counter-clockwise = blade

moves to the front.

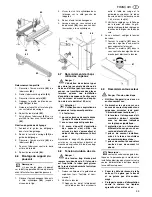

Speed adjustment

By shifting the drive belt the band saw

can be operated at two speeds (see

"Technical Specifications"):

370 m/min for hard wood, plastics

and non-ferrous metals (with special

band saw blade);

800 m/min for all kinds of wood.

34

35

36

4.

Transport

5.

Machine Details

37

38

39

40

41

42

Summary of Contents for BAS 317 Precision WNB

Page 53: ...ZA0091_1 fm 3 1 2 4 6 5 ...

Page 54: ......

Page 55: ......

Page 56: ...U4BA_M1 FM ZINDEL AG Technische Dokumentation und Multimedia www zindel de www metabo com ...