19

ENGLISH

A

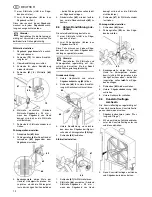

Caution!

The drive belt must not run in a

diagonal position; this will damage

the belt

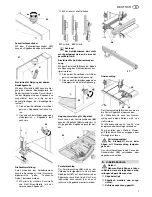

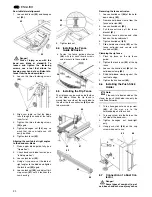

Setting knob for drive belt tension

With the setting knob

(43)

the drive belt

tension is corrected, if necessary:

turning the setting knob clockwise

reduces the blade tension;

turning the setting knob counter-

clockwise increases the blade ten-

sion.

Saw table tilt

After loosening the lock screw

(44)

the

saw table

(45)

tilts steplessly through

47° against the blade.

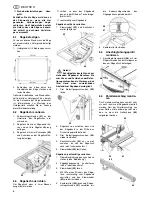

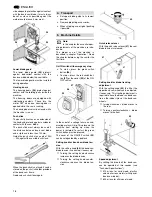

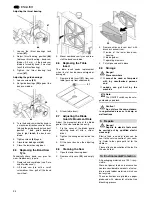

Rip fence

The rip fence

(46)

clamps to the front of

the bandsaw table; in addition it is held

in position by the hold-down clamp

(47)

at the rear of the bandsaw table. The rip

fence can be used on both sides of the

blade.

Mitre fence

The mitre fence

(49)

is inserted into the

table slot from the table’s front edge.

For mitre cuts the mitre fence turns to

60° in both directions.

For 45° and 90° miters positive stops are

provided.

To set a mitre angle: loosen lock handle

(48)

by turning it counter-clockwise.

A

Risk of injury!

When cutting with the mitre

fence the lock handle must be firmly

tightened.

The auxiliary fence extrusion can be

taken off and reversed after loosening

knurled nut

(50)

.

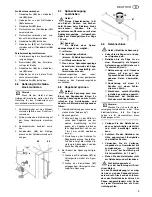

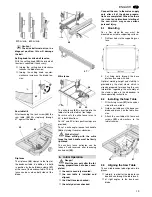

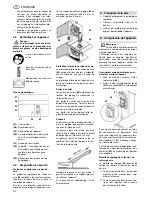

A

Danger!

Start the saw only after the fol-

lowing preparations have been com-

pleted:

the saw is securely mounted;

the saw table is installed and

aligned;

the V-belt tension checked;

the safety devices checked.

Connect the saw to the mains supply

only after all of the above prepara-

tions are completed! Otherwise there

is a risk of an unintentional starting of

the saw, which may cause serious

personal injury.

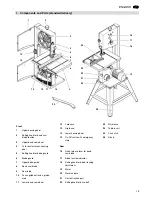

6.1

Mounting

For a firm stand the saw must be

mounted on a stable supporting surface:

1.

Drill four holes in the supporting sur-

face.

2.

Put fixing bolts through the base

plate and secure with nuts.

Optimal working height and stability is

provided by the steel stand, which is

already prepared for mounting the saw.

Information regarding the assembly of

the stand is given in the addendum to

these operating instructions.

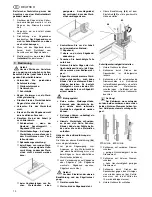

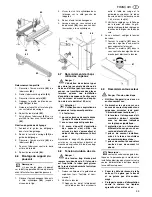

6.2

Installing the Saw Table

1.

Fit limit stop screw

(51)

to the under-

side of the saw table.

2.

Guide saw table over the band saw

blade and place it on the table trun-

nion.

3.

Attach the saw table with four each

screws

(52)

and washers to the

table trunnion.

6.3

Aligning the Saw Table

The saw table needs to be aligned in two

planes

laterally, in order for the blade to run

dead centre through the table insert;

at right angles to the band saw

blade.

800 m/min

370 m/min

43

44

45

6.

Initial Operation

46

47

48

49

50

51

52

Summary of Contents for BAS 317 Precision WNB

Page 53: ...ZA0091_1 fm 3 1 2 4 6 5 ...

Page 54: ......

Page 55: ......

Page 56: ...U4BA_M1 FM ZINDEL AG Technische Dokumentation und Multimedia www zindel de www metabo com ...