20

ENGLISH

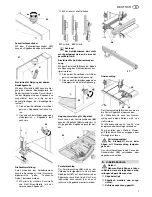

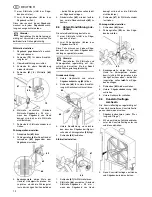

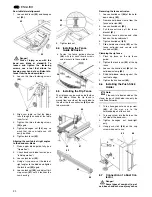

Saw table lateral alignment

1.

Loosen lock lever

(53)

and hexagon

nut

(54)

.

A

Danger!

Risk of injury, even with the

band saw blade at standstill. To

loosen and tighten the fastening

screws use a tool that allows for

keeping your hand at a sufficient dis-

tance from the band saw blade.

2.

Loosen the three fastening screws

(55)

.

3.

Align saw table so that the blade

runs through the centre of the table

insert's slot.

4.

Tighten the three fastening screws

(55)

again.

5.

Tighten hexagon nut

(54)

only so

much that the saw table can still

easily be tilted.

6.

Tighten lock lever

(53)

.

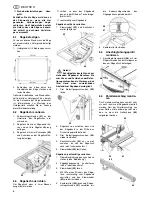

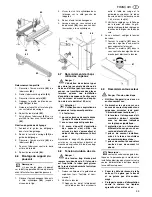

Aligning the saw table at right angles

to the band saw blade

1.

Raise upper blade guide fully (see

"Operation").

2.

Check band saw blade tension (see

"Initial operation").

3.

Loosen lock lever

(53)

.

4.

Using a try square, set the table at

right angles to the blade and tighten

the lock lever

(53)

again.

5.

Loosen lock nut

(56)

and adjust limit

stop screw

(57)

until it touches the

saw housing.

6.

Tighten lock nut.

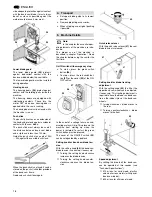

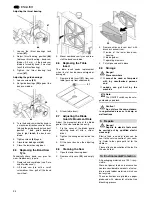

6.4

Installing the Fence

Guide Extrusion

x

Fasten the fence guide extrusion

(58)

with four each thumb screws

and washers to the saw table.

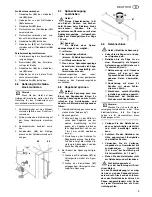

6.5

Installing the Rip Fence

The rip fence can be used on both sides

of the blade. When the rip fence is

moved from one side of the saw blade to

the other the fence extrusion

(60)

needs

to be reversed.

Reversing the fence extrusion

1.

Loosen knurled nut

(64)

of the hold-

down clamp

(63)

.

2.

Remove hold-down clamp from the

fence extrusion

(60)

.

3.

Loosen knurled nut

(62)

.

4.

Pull fence extrusion off the fence

bracket

(61)

.

5.

Reverse fence extrusion and slide

back on the fence bracket.

6.

Tighten knurled nut

(62)

.

7.

Slide hold-down clamp

(63)

on the

fence extrusion and secure with

knurled nut

(64)

.

Clamping the rip fence

1.

Place rip fence on the rip fence

guide.

2.

Tighten the lock lever

(59)

of the rip

fence.

3.

Loosen the knurled nut

(64)

of the

hold-down clamp

(63)

.

4.

Slide hold-down clamp against the

rear table edge.

5.

Tighten the knurled nut

(64)

.

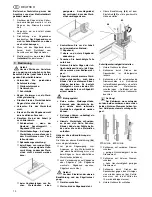

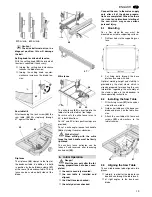

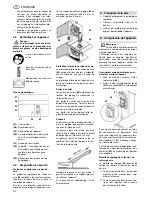

6.6

Installing the Push Stick

Holder

3

Note:

If the saw is to be mounted on the

stand, the push stick holder can only be

installed afterwards.

1.

Turn a hexagon nut on a cap screw

(65)

, all the way up to the

unthreaded part of the shank.

2.

Turn cap screw into the hole on the

left side of the band saw.

3.

Tighten hexagon nut hand-tight

only.

4.

Hang push stick

(66)

on the cap

screw when not in use.

6.7

Connection of a Dust Col-

lector

A

Danger!

Some types of saw dust (e.g. of

oak, beech and ash wood) may cause

54

53

55

57

56

58

59

60

61

62

63

64

65

66

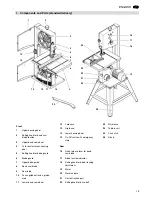

Summary of Contents for BAS 317 Precision WNB

Page 53: ...ZA0091_1 fm 3 1 2 4 6 5 ...

Page 54: ......

Page 55: ......

Page 56: ...U4BA_M1 FM ZINDEL AG Technische Dokumentation und Multimedia www zindel de www metabo com ...