21

ENGLISH

cancer when inhaled: always use a

dust collector when working indoors

(required air speed at the saw's suc-

tion connector

t

20 m/s).

A

Caution!

Operation without a dust col-

lector is only possible:

outdoors;

for short-term operation

(up to 30 minutes maximum);

with dust respirator.

If no dust collector is used chips will

accumulate, which need to be

removed periodically.

Connect dust collector or industrial vac-

uum with a suitable adaptor to the dust

extraction port.

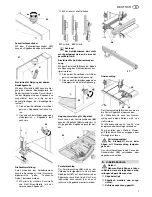

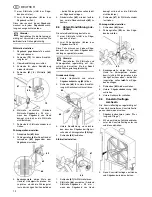

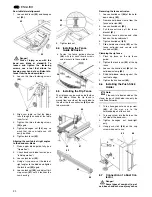

6.8

Tensioning the Band Saw

Blade

A

Danger!

Too much tension can cause

the band saw blade to break. Too little

tension can cause the driven band

saw wheel to slip and the band saw

blade to stop.

1.

Raise upper blade guide fully (see

"Operation").

2.

Checking the blade tension:

Check tension by pushing with a

finger, halfway between table and

upper blade guide, against the

side of the blade (the blade

should flex not more than 1-2

mm).

Check adjustment at the blade

tension indicator. The scale indi-

cates the correct adjustment in

dependence on the band saw

blade width.

3.

Correct tension if necessary:

turning the setting knob

(67)

counter-clockwise increases the

blade tension.

turning the setting knob

(67)

counter-clockwise reduces the

blade tension.

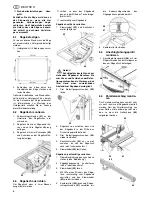

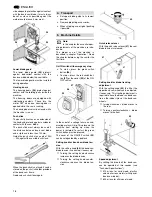

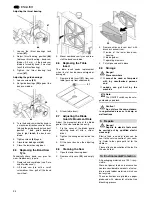

6.9

Connection to Power

Mains

B

Danger! High voltage

x

Operate the saw in only in a dry

environment.

x

Operate the saw only on a power

source matching the following

requirements (see also "Techni-

cal Specifications"):

mains voltage and system fre-

quency conform to the voltage

and frequency shown on the

machine's name plate;

fuse protection by a residual

current operated device (RCD)

of 30 mA sensitivity;

outlets properly installed,

earthed and tested;

three-phase outlets with neu-

tral wire installed;

3

Note:

Check with your local Electricity

Board or your electrician if in doubt

whether your house service connection

meets the requirements.

x

Make sure the power supply

cable is out of the way, so that it

does not interfere with the work

and does not pose a tripping haz-

ard or will get damaged.

x

Protect the power supply cable

from heat, aggressive liquids and

sharp edges.

x

Use only rubber-insulated exten-

sion cables of sufficient lead

cross section (3 x 1.5 mm

2

, for

machines with 3-phase motor:

5 x 1.5 mm

2

).

x

Do not pull on the power supply

cable to unplug.

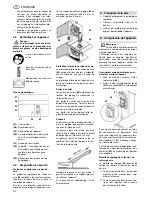

A

Changing the direction of rota-

tion (3-phase motor only):

Depending on phase sequence the

band saw blade may turn in the wrong

direction. This can cause the work

piece being tossed away when

attempting to cut. Therefore, always

check direction of rotation after every

connection to the power supply.

If the direction of rotation is incorrect,

the electrical connection must be

changed by a qualified electrician!

1.

When the saw is assembled and all

safety devices are installed, connect

it to the power supply.

2.

Start saw briefly and turn OFF

immediately again.

3.

Check the band saw blade's direc-

tion of rotation:

in the cutting area

it must run from the top down-

wards.

4.

If the band saw blade turns in the

wrong direction, unplug the power

supply cable at the saw.

5.

Have the electrical connection

changed

by a qualified electrician

!

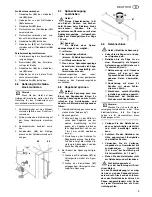

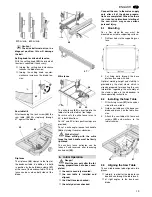

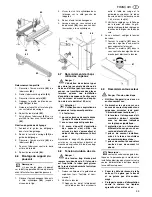

A

Danger!

To reduce the risk of personal

injury as much as possible, the fol-

lowing safety recommendations

should be observed when operating

the saw.

x

Use personal protection gear:

dust respirator;

hearing protection;

safety goggles.

x

Cut only one work piece at a time.

x

Always hold the work piece down

on the table.

x

Do not jam any work pieces.

x

Do not try to slow the band saw

blade down or stop it by pushing

the work piece against the saw

blade from the side.

x

If the type of work requires, use

the following:

push stick – if distance rip

fence – band saw blade

d

120 mm;

work support – for long stock,

which would otherwise fall off

the table on completion of the

cut;

dust collector;

an appropriate jig when cutting

round stock, to keep it from

turning;

a suitable guide for firm sup-

port when cutting thin stock

layed on edge.

x

Before starting work, check to

see that the following are in

proper working order:

band saw blade;

upper and lower blade guard.

x

Replace damaged parts immedi-

ately.

x

Assume correct work position

(the band saw blade's teeth must

point towards the operator).

67

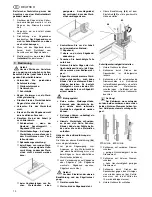

7.

Operation

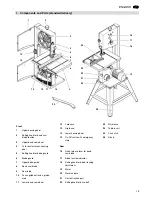

Summary of Contents for BAS 317 Precision WNB

Page 53: ...ZA0091_1 fm 3 1 2 4 6 5 ...

Page 54: ......

Page 55: ......

Page 56: ...U4BA_M1 FM ZINDEL AG Technische Dokumentation und Multimedia www zindel de www metabo com ...