ENGLISH

en

16

Wear non-slip foot protection.

Do not use metal saw blades.

Wear gloves.

Beware of kickback.

Beware of parts being ejected.

See pages 2 and 3.

1 Rod (ergonomically curved)

2 Handle

3 Suspension point

4 Handle

5 Switch lock

6 Switch (switching on/off, setting speed)

7 FSD 36-18 LTX BL 40: step limiter (do not use

as handle)

8 Arrows show the direction of rotation of the

cutting tools

9 Thread cutter (WARNING! Danger of injury

from the sharp edges of the blade)

10 Safety guard

11 Cutting head

12 Battery pack release button

13 Capacity indicator button *

14 Battery pack(s) *

15 Capacity and signal indicator *

16 Thread (cutting line)

17 Cap (of the line head)

18 Base body (of the line head)

19 Shackle (guard)

20 Screw (to fix the guard)

21 Rod (to lock the drive shaft)

22 Drilled hole (to lock the drive shaft)

23 Drive shaft

24 Blades

25 Disc

26 Clamping cap

27 Clamping nut

28 Combination wrench

29 Thread head

30 Screws of the handle

31 Wing nut

32 Handle bar

33 Cable holder

34 Shoulder strap

35 Carabiner hook

*equipment-specific

WARNING! Switch off the machine and

remove (14) battery packs. Unintentional

startup can cause serious injuries. The machine

must be stationary.

WARNING! Danger of injury from sharp

cutting edge on the line cutter (9) and blade

(24). Wear protective gloves.

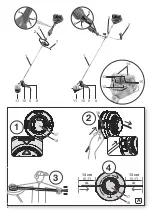

6.1 Attaching the guard (10) (fig. B)

WARNING! Danger of injury from sharp

cutting edge on the line cutter (9). Wear

protective gloves.

1. Hook the guard (10) into the shackle (19).

2. Insert the screw (20) and firmly tighten it.

6.2 Attaching / removing the line head (29)

(fig. C)

Fitting

1. Locking the drive shaft (23):

- insert the supplied rod (21) into the drilled hole

(22).

- Turn the drive shaft (23) by hand until the rod

(21) engages and the drive shaft cannot be

turned anymore.

2. As shown, screw on the line head (29) in anti-

clockwise direction and tighten by hand.

3. Release the drive shaft:

Removal

Proceed in the same way as for the attachment,

however unscrew the line head in clockwise

direction.

6.3 Insert cutting line (16) in line head (29)

(fig. A)

1. Hold tight the base body (18) . Turn the cap (17)

in clockwise direction until the triangular marks

are opposite each other (and/or the continuous

groove on the side of the print head is aligned

with the triangle of the line head’s cap).

2. Bend the end of the line straight (so that it can be

inserted more easily).

Push the line end (16) into the opening marked

with an arrow and the words “LINE IN. NOTE:

See fig. A: Push in exactly in the direction of the

arrow (slightly slanted)!

Result: The line end emerges from the opposite

opening.

3. Pull out the shorter line until both lines are of

equal length.

4. Hold tight the base body (18) . Turn the cap (17)

in clockwise direction: The line is wound up in

the base body. Stop when 13 cm (5.1“) of line

still protrudes on both sides. (A line that is too

long is automatically cut off by the line cutter (9)

).

6.4 Fitting / removing the blade (fig. D)

Fitting

1. Locking the drive shaft (23):

5. Overview

6. Initial Operation

Summary of Contents for FSB 36-18 LTX BL 40

Page 96: ...el 96 1 2 3 6 2000 14 VI 4 LWA G 5 4 1 2 3...

Page 97: ...el 97 4 1 4 2 4 3 24 4 4 6 4...

Page 98: ...el 98 4 5 4 6 130 C 265 F...

Page 99: ...el 99 Li Ion UN 3480 UN 3481 Metabo 4 7 15 m 2 3 1 2 5...

Page 104: ...el 104 ah Kh LpA LWA KpA KWA LWA G 2000 14...

Page 113: ...ru 113 1 2 3 6 2000 14 E VI 4 LWA G 5 4 1 2 3...

Page 114: ...ru 114 4 1 4 2 4 3 24 4 4 4...

Page 115: ...ru 115 6 4 5 4 6...

Page 116: ...ru 116 130 C 265 F UN 3480 UN 3481 Metabo 4 7 15...

Page 122: ......

Page 123: ......

Page 124: ...Metabowerke GmbH Metabo Allee 1 72622 Nuertingen Germany www metabo com 170 27 6560 0221...