ENGLISH

en

14

Observe the relevant guidelines for your

material, staff, application and place of

application (e.g. occupational health and safety

regulations, disposal).

Collect the generated particles at the source,

avoid deposits in the surrounding area.

Use the supplied dust collection unit and a

suitable extraction unit. This ensures that fewer

particles enter the environment in an

uncontrolled way.

Reduce dust exposure with the following

measures:

– Do not direct the escaping particles and the

exhaust air stream at yourself or nearby

persons or on dust deposits.

– Use an extraction unit and/or air purifiers

– Ensure good ventilation of the workplace and

keep clean using a vacuum cleaner Sweeping

or blowing stirs up dust

– Vacuum or wash the protective clothing Do not

blow, beat or brush

Hazard generated by modification of

the machine or use of parts not tested and

approved by the equipment manufacturer!

Assemble tool in strict accordance with these

instructions.

Use only parts approved by the equipment

manufacturer. This applies especially for:

– saw blades (for order numbers, refer to

– Safety devices.

– Cutting laser

– Illumination of cutting line

Do not change any parts.

Ensure that the speed indicated on the saw

blade is at least the same as the speed

indicated on the saw.

Hazard generated by tool defects!

Before every use check tool for possible

damage: before operating the tool all safety

devices, protective guards or slightly damaged

parts need to be checked for proper function as

specified. Check to see that all moving parts

work properly and do not jam. All parts must be

correctly installed and fulfil all conditions

necessary to ensure perfect operation of the

unit.

Do not used any damaged or contorted saw

blades.

Risk of injury by noise!

Wear hearing protection.

Danger from blocking workpieces or

workpiece parts!

If blockage occurs:

1. switch machine off,

2. Pull the mains plug or remove the detachable

battery pack,

3. wear gloves,

4. clear the blockage using a suitable tool.

4.2 Special safety instructions for

cordless machines:

Remove the battery pack from the machine before

making any adjustments, changing tools,

maintaining or cleaning.

Protect battery packs from water and

moisture!

Do not expose battery packs to fire!

Do not use faulty or deformed battery packs!

Do not open battery packs!

Do not touch contacts or short-circuit battery

packs!

A slightly acidic, flammable fluid may leak

from defective Li-ion battery packs!

If battery fluid leaks out and comes into

contact with your skin, rinse immediately

with plenty of water. If battery fluid leaks out

and comes into contact with your eyes, wash them

with clean water and seek medical attention

immediately!

4.3 Symbols on the machine

(depends

on model)

Read the operating instructions.

Never place hands into running saw

blade.

Wear protective goggles and ear

protectors.

Never operate the tool in a damp or wet

environment.

Laser radiation - Do not look

into the light beam.

LASER CLASS 2

4.4 Safety devices

The retractable blade guard protects against

unintentional contact with the saw blade and from

chips flying about.

Cordless tools: The machine can only be

switched on when the safety lock is activated.

Mains-powered tools: The retractable blade

guard opens and the saw can be lowered only

when the safety lock is activated.

Parallel guide/ ripping fence (26)

The parallel guide/ ripping fence prevents that the

workpiece can be moved during the cutting

process. During operation, the parallel guide/

ripping fence always has to be installed.

Make sure the additional profile

correctly to support the workpiece in the best

manner possible and will not interfere with the

blade or the guard. Lock using the set screw

.

The additional profile

at the parallel guide/

ripping fence has to be moved for inclined cuts

after loosening the set screw

See page 2.

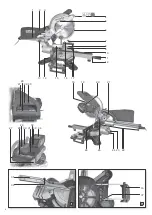

1 Closing the chip bag

2 Chip bag

3 Chip extraction nozzle

4 Laser beam egress point

5 Cutting line illumination

6 Retractable blade guard

7 Longitudinal stop

8 Table

9 Turntable

10 Table insert

11 Locking lever for turntable

12 Safety catch for stop positions of the turntable*

13 Set screw for pulling device*

14 Allen key / tool storage for Allen key

15 Work clamp

16 Table extension

17 Locking screw of the table width extension

18 Saw blade lock

19 Saw handle

20 Speed adjustment wheel *

21 Handle

22 Hook for cable winding

23 Locking lever for setting the angle of inclination

24 Locking button (to extend the angle of

inclination by +/- 2 °)

25 Transport lock

26 Parallel guide / ripping fence

27 Safety lock

28 On/off switch of the saw

29 On/off switch of the cutting laser

30 On/off switch of the cutting line illumination

31 Battery pack release button *

32 Capacity indicator button *

33 Capacity and signal indicator *

34 Battery pack*

* depends on model / equipment

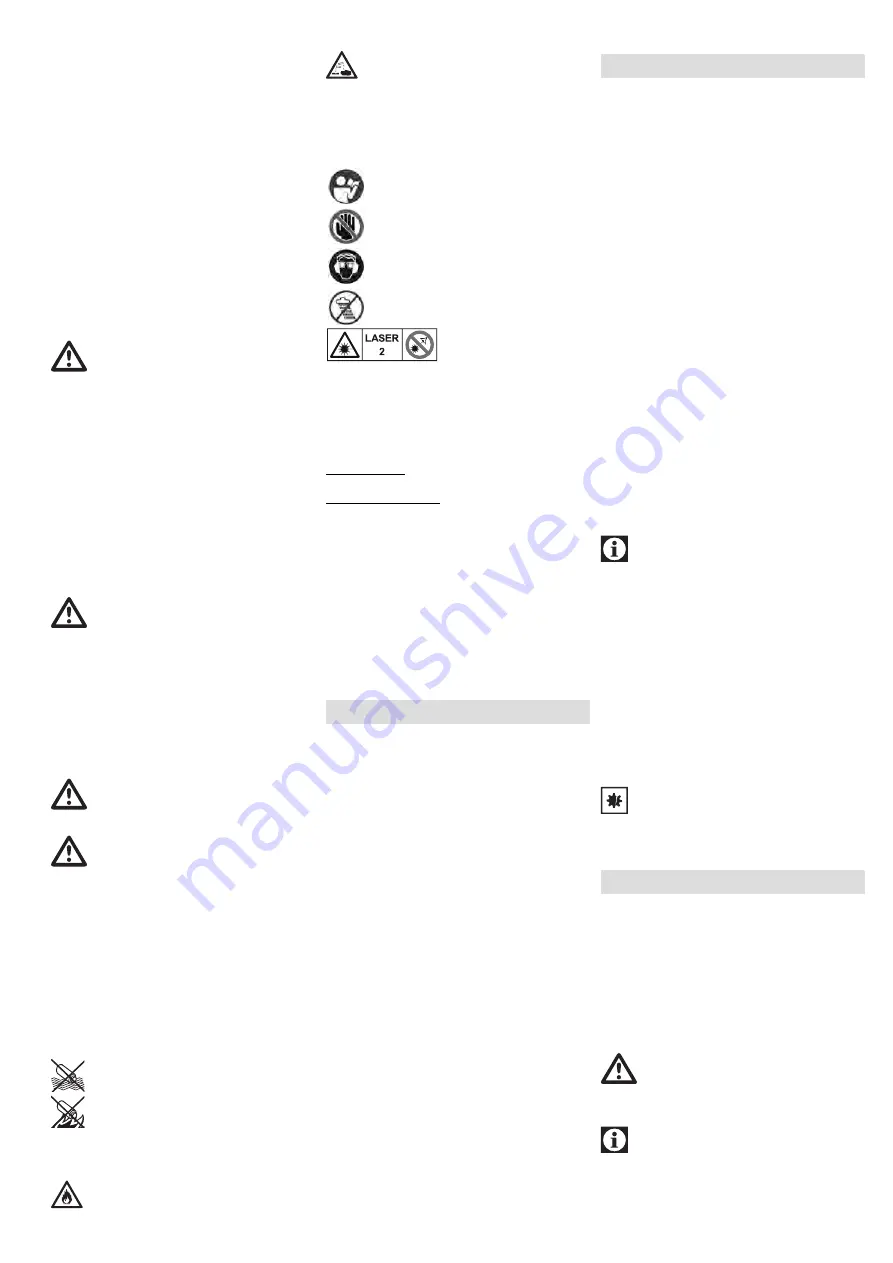

Install handle (21) if required (depending on

model)

Fix the handle

Install table width extension (16) if required

(depending on model)

1. Remove right and left table width extension

from the transport packaging.

2. Remove screws

right and left table width extension.

3. Push the guide rails of the table width

extensions completely into the recesses.

Insert the table width extension with folding

length guide

on the right side.

4. Lift the device at the front legs, carefully tilt it

backwards and put it down so it will not fall

over.

5. Tighten again the screws

rails.

6. Take the front legs of the device, carefully tilt it

forwards and put down.

7. Set the desired table width and lock the table

width extensions with locking screws

.

Installation

The device has to be mounted on a stable

support for safe working.

– The support can be either a firmly mounted work

top or work bench.

– Even when machining larger workpieces the

device has to have a secure stand.

– Long workpieces must get additional support

with suitable accessories.

Note:

For mobile use, the device can also be fixed to a

plywood or coreboard panel (500 mm x 500 mm,

at least 19 mm thick) using screws. During use,

the panel has to be fixed to a work bench using

screw clamps.

1. Fix device to the support using screws.

2. Loosen transport lock

slightly downwards and hold. Pull out transport

3. Swivel saw head slightly upwards.

Transport

1. Swivel saw head downwards and push in

transport lock

2. Lock the pulling device in the front position

using the set screw

Caution!

Do not hold the saw at the protective installations

during transport.

3. Lift the device at the handle

7.1 On/Off switch motor

Switching on the motor:

Press the on/off switch and keep pressed.

Switching off the motor:

Let go of the on/off switch.

7.2 On/off switch cutting line

Switching on/ off the illumination of the cutting

line.

Danger!

Do not direct the light beam into the eyes of

people or animals.

Note:

Cordless devices: During a short break the cutting

line illumination goes off (sleep mode) and is

automatically reactivated when resuming work. In

case of a long break the cutting line illumination

switches off automatically. Reactivation: Use

switch

.

5. Overview

6. Setup and transport

7. The device in detail