ENGLISH

en

15

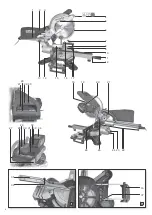

7.3 On/off switch cutting laser

Switching on/off of the cutting laser.

The cutting laser marks a line to the left of the

saw's cut. Make a trial cut to become familiar with

the positioning.

Danger!

LASER BEAM

DO NOT LOOK INTO THE BEAM

LASER CLASS 2

EN 60825-1:2014

P<1mW,

λ

=650nm

Note:

Cordless devices: During a short break the cutting

laser goes off (sleep mode) and is automatically

reactivated when resuming work. In case of a

long break the cutting laser switches off.

7.4 Setting the angle of inclination

After loosening the locking lever

can be infinitely inclined between 0° and 45° to

the left of the vertical position

adjustment process in order to also set angles up

to 47° to the left of the vertical/ up to 2° to the right

of the vertical.

Danger!

In order for the angle of inclination not to change

when cutting, the locking lever

arm has to be tightened.

You can adapt the position of the locking lever

according to your requirements: pull out locking

lever, turn and push in the desired position and let

engage.

7.5 Turntable

After loosening the locking lever

activating the safety catch

be turned by 47° to the left or by 47° to the right

for mitre cuts. In this manner the cutting angle to

the support edge of the workpiece is adjusted.

Danger!

In order for the mitre angle not to change during

cutting, the locking handle

to be tightened (also in the stop positions!).

7.6 Pulling device

Using the pulling device, also larger workpieces

with greater cross sections can be cut. The

pulling device can be used for all types of cuts

(straight cuts, mitre cuts, slanted cuts and double

mitre cuts, and cutting of grooves).

If the pulling device is not required, lock the

pulling device in the rear position using the set

screw

.

7.7 Cutting depth limitation

Together with the pulling device the cutting depth

limitation

permits the cutting of grooves.

Turn the set screw and fix with the counter nut.

The cutting depth limitation can be deactivated, if

is pushed towards the rear.

7.8 Setting the speed

only for KGSV 216 M,

KGSM 216 Vario Max)

Select the speed at the setting wheel

. See

table for recommended setting wheel positions.

Wood: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 6

Aluminium: . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 6

Plastic: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 3

8.1 Connect chip sack / chip and dust

extraction unit

Danger!

Dust of certain timber species (e.g. beech, oak,

ash) can cause cancer when inhaled.

– Only use a suitable dust extraction unit or

installed dust sack.

– In addition, use a dust mask, as not all saw dust

is collected or extracted.

– Regularly empty the dust sack. Wear a dust

mask while emptying the sack.

If you operate the device with the supplied dust

sack:

adapter nozzle

If you connect the device to a dust extraction unit:

Use a suitable adapter to connect it to the chip

extraction adapter nozzle (see chapter 12.

"Accessories").

Ensure that the dust extraction unit meets the

requirements stated in chapter 16. "Technical

Specifications".

Observe the dust collector's operating

instructions as well!

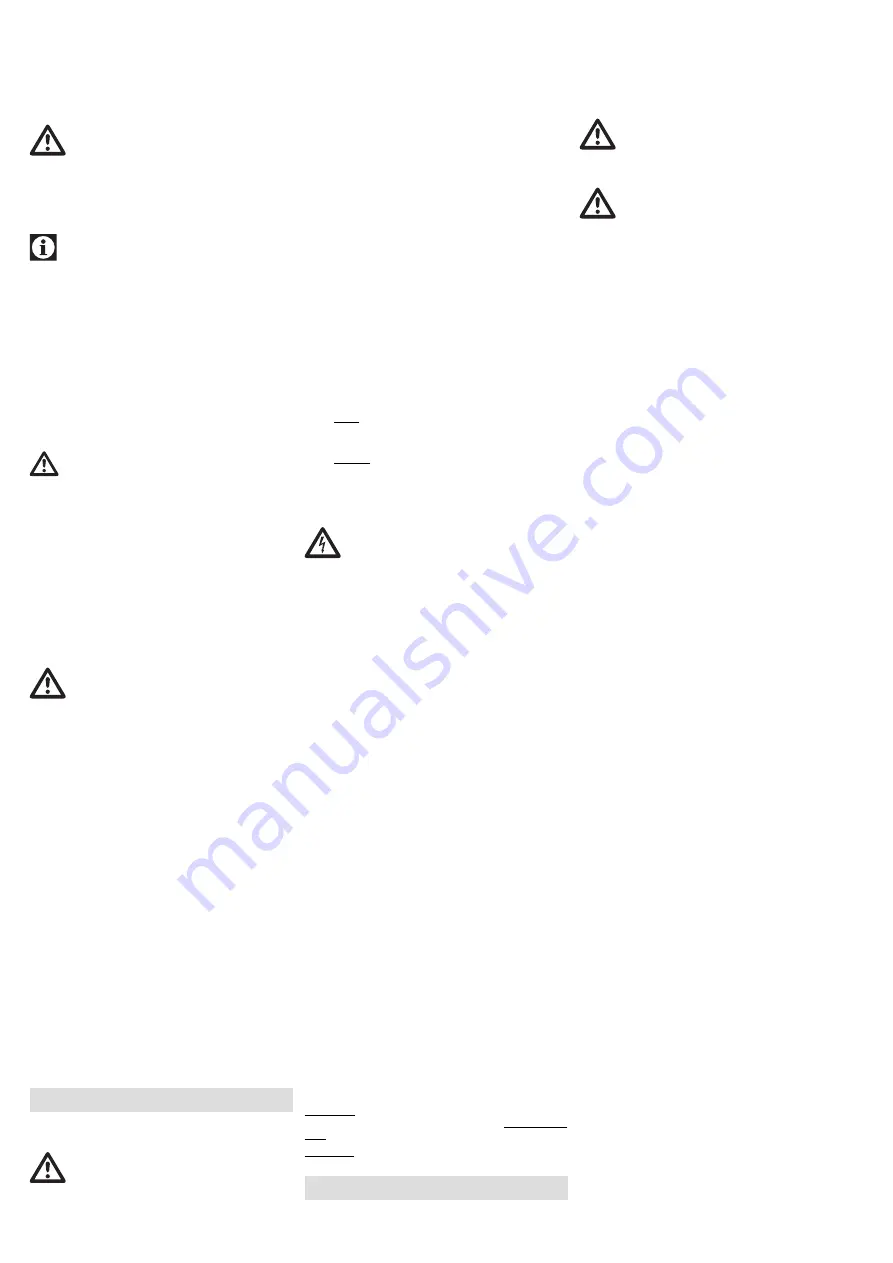

8.2 Installing the workpiece clamping

device

installed in two positions:

– For wide workpieces:

Insert the workpiece clamping device into the

rear drilling

– For narrow workpieces:

Insert the workpiece clamping device into the

front drilling

8.3 For mains powered machines only

Danger! High voltage

Operate machine only on a power source meeting

the following requirements (see also chapter 16.

"Technical Specifications"):

– Mains voltage and system frequency must

conform to the voltage and frequency shown on

the machine´s rating label;

– fuse protection by a residual current operated

device (RCD) of 30 mA sensitivity;

– outlets properly installed, earthed or grounded,

and tested.

Position power supply cable so it does not

interfere with the work and is not damaged.

Use only rubber-jacketed extension cables with

sufficient lead cross-section (3 × 1.5 mm

2

).

Use extension cables for outdoor areas. When

working outdoors, only use the correspondingly

marked extension cable approved for this

purpose.

Avoid accidental start-up. Ensure that the on/off

switch is switched off when inserting the plug in

the socket.

8.4 For cordless machines only

Avoid accidental start-up. Before fitting the

battery pack, make sure that the machine is

switched off.

Battery pack

Charge the battery pack

If performance diminishes, recharge the battery

pack.

The ideal storage temperature is between 10°C

and 30°C.

Li-Ion battery packs "Li-Power" have a capacity

and signal indicator

charge level.

- If one LED is flashing, the battery pack is almost

flat and must be recharged.

Removing and inserting the battery pack

Removal: Press the battery pack release button

(31)

and pull out the battery pack

towards the

rear.

To insert: Slide the battery pack

engages.

Before starting work, check to see that the

following are in proper working order.

Assume proper operating position:

– at the front of the saw;

– in front of the saw;

– next to the line of cut.

Danger!

If possible, fix the workpiece using the workpiece

clamping device

Danger of crushing!

When inclining or swivelling the saw head, never

reach into the hinge area or below the device!

Hold the saw head during inclination.

Use during work:

– workpiece support – for long workpieces, if

otherwise workpiece would fall off the table

after cutting;

– dust sack or dust extraction unit.

Cut only workpieces of dimensions that allow for

safe and secure holding while cutting.

Always hold the workpiece down on the table

and do not jam it. Do not attempt to stop the saw

blade by pushing the workpiece against its side.

Risk of personal injury if the saw blade is

blocked.

9.1 Straight cuts

Starting position:

– Transport lock

– Saw head swivelled upwards.

– Cutting depth limitation

deactivated.

– Turntable is in 0

°

for turntable is tightened.

– The inclination of the swivel arm to the vertical is

0

°

for inclined position is

tightened.

– Pulling device at the very rear.

– Set screw

of the pulling device has been

– Set workpiece stop

Release locking screw

workpiece is supported in the best manner

possible and will not interfere with the blade or

the guard. Fasten with locking screw

Cutting the workpiece:

1. Push the workpiece against the parallel guide/

ripping fence and clamp using the workpiece

clamping device

.

2. For wider workpieces: pull the saw head

forwards (towards the operator) (pulling

device).

3. Activate the safety lock

,press on/off

4. Slowly lower the saw head at the handle all the

way down and, if required, push towards the

rear (away from the operator). During the

sawing process press on the workpiece just

enough for the motor speed not to lower too

much.

5. Cut the workpiece in one operation.

6. Release the on/off switch

the saw head swivel back into the upper

starting position.

9.2 Mitre cuts

Starting position:

– Transport lock

– Saw head swivelled upwards.

– Cutting depth limitation

deactivated.

– Inclination of the swivel arm to the vertical is 0°,

tightened.

– Pulling device at the very rear.

– Set screw

of the pulling device has been

loosened.

– Set workpiece stop

Release locking screw

workpiece is supported in the best manner

possible and will not interfere with the blade or

the guard. Fasten with locking screw

.

8. Commissioning

9. Operation