ENGLISH

en

16

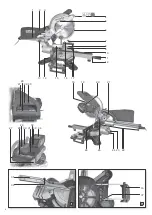

Cutting the workpiece:

1. Loosen locking lever

loosen safety catch

2. Set the desired angle.

3. Tighten the locking button

of the

turntable.

4. Cut workpiece, as described for "Straight

cuts".

9.3 Inclined cuts

Starting position:

pulled out.

– Saw head swivelled upwards.

– Cutting depth limitation

– Turntable is in 0

°

position, locking button

for turntable is tightened.

– Set screw

of the pulling device has been

– Pulling device at the very rear.

– Set workpiece stop

:

Release locking screw

. Move the

additional profile

workpiece is supported in the best manner

possible and will not interfere with the blade or

the guard. Fasten with locking screw

For particular angle settings it might be

necessary to completely pull out the additional

, after loosening the locking screw

. (After the

saw cut, reattach the additional profile

fasten with locking screw

lost.)

Cutting the workpiece:

1. Loosen the locking lever

for the

inclination setting at the rear side of the saw.

2. Slowly tilt the swivel arm into the desired

position.

3. Tighten the locking lever

for the

inclination setting.

4. Cut the workpiece, as described for "Straight

cuts".

9.4 Double mitre cuts

Note:

The double mitre cut is a combination of mitre cut

and inclined cut. This means, the workpiece is cut

at an angle to the rear contact edge

and

at an

angle to the top.

Danger!

With a double mitre cut, the saw blade is easier

accessible due to the steep inclination – this

results in a higher risk of injury. Always keep

sufficient distance to the saw blade!

Starting position:

pulled out.

– Saw head swivelled upwards.

– Cutting depth limitation

– Lock the turn table in the desired position.

– Swivel arm inclined at desired angle to the

workpiece surface and locked.

– Set screw

of the pulling device has been

– Pulling device at the very rear.

– Set workpiece stop

:

Release locking screw

. Move the

additional profile

workpiece is supported in the best manner

possible and will not interfere with the blade or

the guard. Fasten with locking screw

For particular angle settings it might be

necessary to completely pull out the additional

, after loosening the locking screw

. (After the

saw cut, reattach the additional profile

fasten with locking screw

lost.).

Cutting the workpiece:

Cut the workpiece, as described for "Straight

cuts".

9.5 Cutting grooves

Note:

The cutting depth limitation together with the

pulling device permits the cutting of grooves. This

does not result in a separating cut, but only a cut

of a certain depth is effected in the workpiece.

Risk of kickback!

When cutting grooves it is particularly important

that no lateral pressure is exerted on the saw

blade. Otherwise, the saw head might suddenly

kick back! Use a clamping device when cutting

grooves. Avoid lateral pressure on the saw head.

Starting position:

– Saw head swivelled upwards.

– Swivel arm inclined at desired angle to the

workpiece surface and locked.

– Lock the turn table in the desired position.

– Set screw

of the pulling device has been

– Pulling device at the very rear

Cutting the workpiece:

1. Set the cutting depth limitation

desired cutting depth and fix with counter nut.

downwards to check the set cutting depth:

3. Effect trial cut.

4. If required, repeat steps 1 and 3 until the

desired cutting depth has been set.

5. Cut the workpiece, as described for "Straight

cuts".

Danger!

Prior to all maintenance and cleaning jobs pull the

mains plug or remove the detachable battery

– Repair and maintenance work other than

described in this section should only be carried

out by qualified specialists.

– Replace damaged parts, in particular safety

installations, only with original parts. Parts not

approved by the equipment manufacturer can

cause unforeseeable damage.

– Check that all safety devices are operational

again after each service.

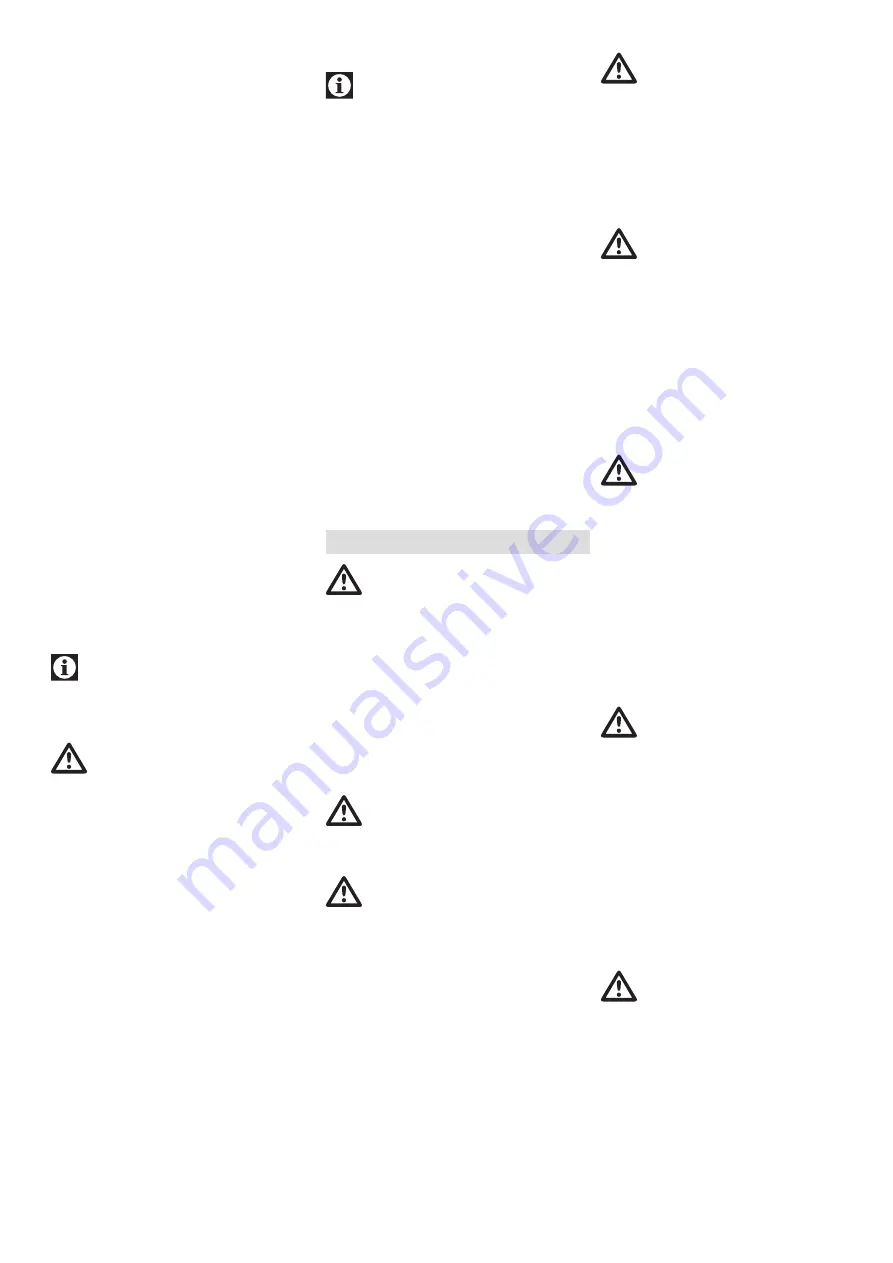

10.1 Saw blade change

Risk of burning!

Directly after cutting the saw blade can be very

hot. Let a hot saw blade cool down. Do not clean

the hot saw blade with combustible liquids.

Risk of injury, even with the blade at

standstill!

When loosening and tightening the tensioning

be swivelled over the saw blade. Wear gloves

when changing blades.

1. Pull the mains plug or remove the detachable

battery pack

.

2. Put the saw head in the upper position.

3. Lock saw blade: press the locking button

and turn the saw blade with the other hand

until the locking button engages. Hold down

the locking button.

4. Remove the tensioning screw with washer

(44)

on the saw blade shaft with Allen key

in clockwise direction (left-hand thread!).

powered devices) and push the retractable

blade guard

upwards and hold.

6. Carefully remove outer flange

from the saw blade shaft and close

again the retractable blade guard.

Danger!

Do not use cleaning agents (e.g. to remove resin

residue) that could corrode the light metal

components of the saw; the stability of the saw

would be adversely affected.

7. Cleaning the clamping surfaces:

– saw blade

– outer flange

– inner flange

Danger!

Place inner flange properly! If this is not the case,

the saw can block or the saw blade could work

loose. The inner flange is in the correct position if

the ring groove points towards the saw blade and

the flat side to the motor.

8. Put on inner flange

9. Loosen safety lock

powered devices) and push the retractable

10.Place a new saw blade - pay attention to

direction of rotation: Seen from the left (open)

side, the arrow on the saw blade has to

correspond to the direction of the arrow

on the saw blade cover!

Danger!

Use only saw blades, which fulfil the requirements

and specifications listed in these operating

instructions.

Use only saw blades designed for the maximum

speed (see "Technical Specifications") – if

unsuitable or damaged saw blades parts are

used, parts can be ejected due to centrifugal

force in an explosive-type manner.

Saw blades intended for cutting wood or similar

materials have to conform to EN 847-1.

Do not use:

– saw blades made of high-alloy speed steel

(HSS);

– damaged saw blades;

– cut-off wheel blades.

Danger!

– Mount saw blade using only genuine parts.

– Do not use loose-fitting reducing rings; the saw

blade could work loose.

– Saw blades have to be mounted in such way

that they do not wobble or run out of balance

and cannot work loose during operation.

11.Close again retractable blade guard

.

13.Put on the tensioning screw with the washer

(44)

in anti-clockwise direction (left-hand

14.Lock saw blade: press the locking button

and turn the saw blade with the other hand

until the locking button engages. Hold down

the locking button.

Danger!

– Do not extend the hexagon wrench.

– Do not tighten the tensioning screw by hitting

the hexagon wrench.

15.Firmly tighten the tensioning screw

the hexagon wrench

16.Check function. Loosen the safety lock

(only for mains-powered devices) and fold the

saw downwards:

– when folding down the retractable blade

guard, it has to provide free access to the saw

blade without touching other parts.

– When folding the saw upwards into the

starting position, the retractable blade guard

has to cover the saw blade automatically.

10. Care And Maintenance