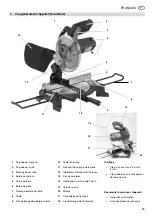

21

ENGLISH

10. Clean clamping surfaces of:

saw spindle

(47)

,

saw blade,

outer blade flange,

inner blade flange

(48)

.

11. Mount the new saw blade –

pay attention to the direction: when

viewed from the left (opened) side,

the arrow on the saw blade must

point in a clockwise direction!

A

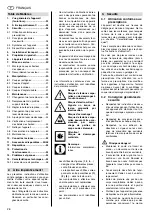

Danger!

Use only suitable saw blades,

designed for the maximum speed

(see "Technical Specifications") –

when using unsuitable or damaged

saw blades, there is a risk of parts

being hurled away explosion-like by

the centrifugal force.

Do not use

:

saw blades made of high speed

steel (HSS);

damaged saw blades;

cut-off wheel blades.

A

Danger!

Mount saw blade using only OEM

parts.

Do not use loose-fitting reducing

rings; the saw blade could work

loose.

Saw blades have to be mounted

in such way that they do not wob-

ble or run out of balance and can

not work loose during operation.

12. Slide the outer blade flange on –

the plain side must point towards the

saw blade!

13. Insert the arbor bolt (left-hand

thread!) and

hand-tighten

it.

To keep the saw blade from turning

press the lock knob, while at the

same time turning the saw blade by

hand until the blade lock engages.

A

Danger!

Do not extend your wrench to get

more leverage.

Do not hit your assembly wrench

with a hammer to tighten the

arbor bolt.

14. Re-install blade cover and flange

guard:

Fit Allen head screw

(45)

and

tighten.

Tigthen screw

(42)

on the right.

15. Insert screw

(41)

again and tighten.

16. Check the function. To do so, push

the safety lock to the side and lower

the sawhead:

The retractable blade guard must

open without touching the saw

blade or any other parts

When returning the sawhead to

its starting position the retracta-

ble blade guard must return auto-

matically so that the entire saw

blade is covered.

Turn the saw blade by hand. The

saw blade must turn freely in any

possible sawhead position with-

out touching other parts.

9.2

Replacing the Table

Insert

A

Danger!

If the table insert is damaged

there is a risk that small parts may

become stuck between table insert

and the saw blade, causing the saw

blade to jam. Replace a damaged

table insert immediately!

1.

Loosen Allen head screws

(49)

.

2.

Remove the fence

(50)

.

3.

Loosen the table insert fixing

screws.

4.

Remove the table insert

(51)

.

5.

Put in a new table insert.

6.

Tighten the table insert fixing

screws.

7.

Install the fence and align it.

9.3

Adjusting the Fence

1.

Loosen Allen head screws

(52)

.

2.

Adjust fence

(53)

so that it is exactly

square with the saw blade when the

rotating table is locked in the 0°

position.

3.

Tighten the Allen head screws.

9.4

Replacing the Laser

Guide's Batteries

A

Laser radiation hazard!

Always disable the laser guide

when servicing the machine!

1.

Unscrew the battery compartment

cover

(54)

.

2.

Remove the battery set (two button

cells AG13).

3.

Insert fresh battery set, positive pole

first. The polarity is imprinted above

the battery compartment.

4.

Screw the battery compartment

cover

(54)

on.

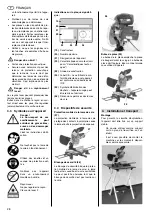

9.5

Adjusting the Laser

Guide

Laser lateral adjustment

x

Turning screw

(57)

in =

seen from operator the cutting line

marking is moved to the right.

x

Turning screw

(57)

out =

seen from operator the cutting line

marking is moved to the left.

Setting the laser to 90 degrees

1.

Loosen grub screws

(56)

and

(58)

.

2.

Use a slotted bit screwdriver on the

plastic part

(55)

to adjust the angle

of the cutting line marking.

47

48

49

50

51

52

53

54

56

57

58

55