14

ENGLISH

−

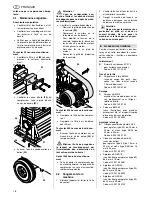

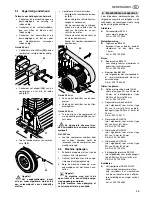

Check gasket of drain cock(s);

replace if necessary.

−

Tighten drain cock(s) fingertight.

•

Check valve leaky.

−

Have check valve serviced by

qualified service centre.

Air tool is not supplied with sufficient

pressure.

•

Pressure regulator not opened wide

enough.

−

Open pressure regulator more.

•

Hose connection between compres-

sor and air tool leaky.

−

Check air hoses, replace defec-

tive parts if necessary.

A

Danger!

Repairs to power tools must be

carried out by qualified electricians

only!

Electric tools in need of repair can be

send to the service centre in your coun-

try. See spare parts list for address.

Please attach a description of the fault to

the power tool.

The machine's packaging can be 100 %

recycled.

Worn out devices and accessories con-

tain considerable amounts of valuable

raw and plastic materials, which can be

recycled.

These instructions are printed on chlo-

rine-free bleached paper.

8.

Repairs

9.

Environmental protection

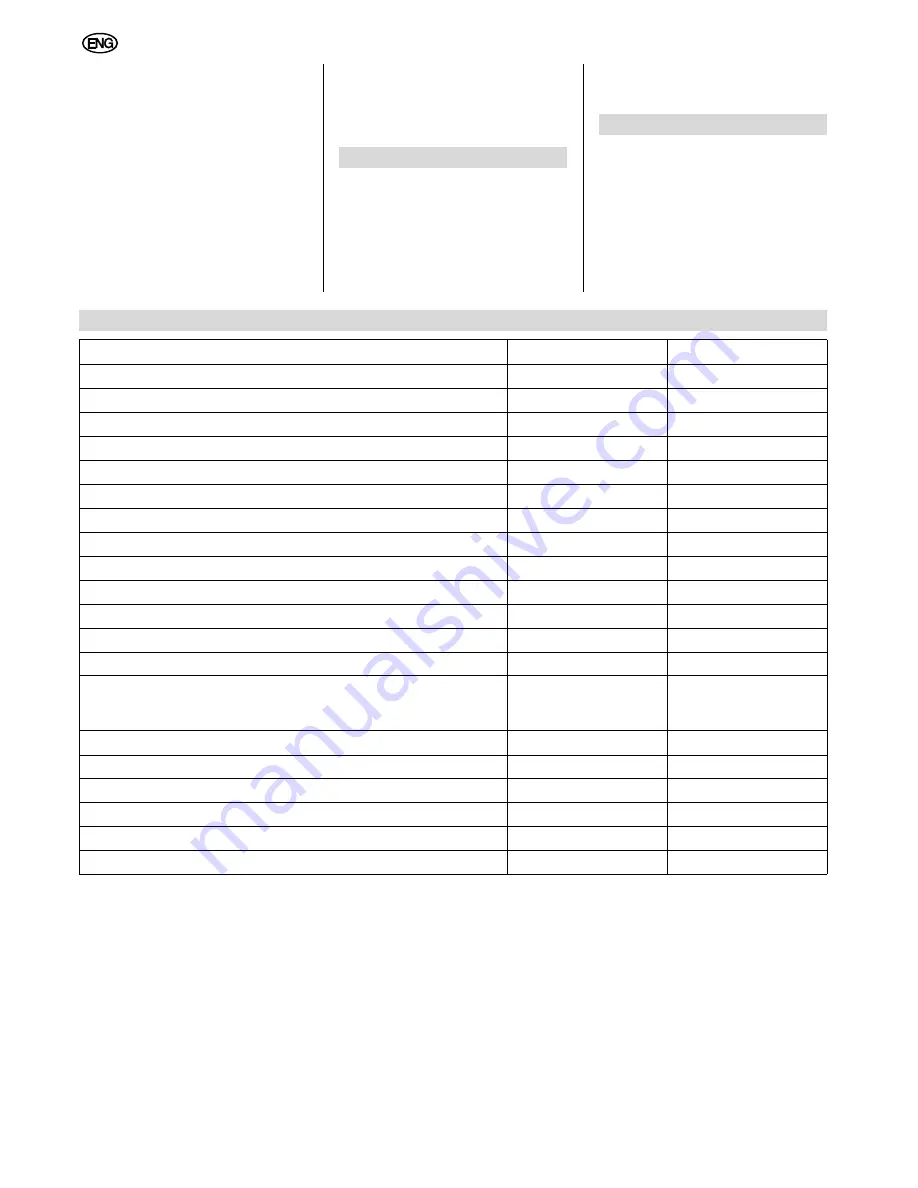

10. Technical specifications

Suction capacity

l/min

290

Free air delivery (volume flow rate)

l/min

165

Filling rate

l/min

195

Working pressure (compression end pressure)

bar

10

Pressure vessel volume

l

50

No. of air outlets

2

Compressor pump model

B 2800

No. of cylinders

2

Speed (compressor pump)

min

-1

1300

Motor capacity

kW

2.0

Supply voltage (50 Hz)

V

230

Rated current

A

9.0

Fuse protection min.

A

16 (time-lag)

Degree of protection

IP 44

Maximum overall length when using extension cables with:

– 3 x 1.5 mm

2

lead cross-section

– 3 x 2.5 mm

2

lead cross-section

m

m

30

50

Oil grade

10 W 40

Oil qantity for oil change

l

0.21

Dimensions: length x width x height

cm

88 x 49 x 77

Weight kg

49

Sound pressure level L

PA

at 4 m maximum

dB (A)

71 ± 3

Sound power level L

WA

dB (A)

91 ± 3