ENGLISH

12

Do not overload the electric tool –

use it only within the performance

range it was designed for (see

'Technical Data').

B

Danger! Risk of electric

shock!

Do not expose the electric tool to

rain.

Do not operate the electric tool in a

damp or wet environment.

Prevent body contact with earthed

objects such as radiators, pipes,

cooking stoves or refrigerators

when operating this electric tool.

Do not use the power cable for pur-

poses it is not intended for.

A

Risk of personal injury by es-

caping compressed air and parts

hurled about by escaping air!

Never direct compressed air against

persons or animals!

Ensure all air tools and accessories

used are designed for the working

pressure or are supplied via a pres-

sure regulator.

Please note that when the quick

coupler is disconnected the com-

pressed air contained in the pres-

sure hose will escape all of a sud-

den. You should therefore firmly

hold the air hose when disconnect-

ing it.

Ensure all screwed connections are

fully tightened at all times.

Do not attempt to repair the device

yourself! Only trained specialists are

permitted to service or repair com-

pressors, pressure vessels and air

tools.

A

Hazard generated by lubricat-

ed compressed air!

Use oil-saturated compressed air

only for air tools requiring such sup-

ply.

Do not use an air hose used to sup-

ply compressed air containing oil to

supply air tools not designed for op-

eration on compressed air contain-

ing oil.

Do not fill tires with compressed air

containing oil.

A

Risk of burns from the surfac-

es of parts carrying compressed air!

Let tool cool off before servicing.

A

Risk of personal injury and

crushing by moving parts!

Do not operate the compressor

without installed guards.

Please note that the compressor will

start automatically when the pres-

sure falls off to minimum! – Discon-

nect from power supply prior to any

servicing.

When turning ON the machine (e.g.

after servicing) ensure that no tools

or loose parts are left on or in the

machine.

A

Hazard generated by insuffi-

cient personal protective equipment!

Wear hearing protection.

Wear safety glasses.

Wear mask respirator when work

generates dust or mist detrimental

to health.

Wear suitable work clothes. When

working outdoors wearing of non-

slip shoes is recommended.

B

Hazard generated by electric

tool defects!

Keep electric tool and accessories

in good repair. Observe the mainte-

nance instructions.

Prior to use check the electric tool

for possible damage: before using

the electric tool carefully check

safety devices, protection devices

and any slightly damaged parts for

proper function as specified. Dam-

aged machines must be properly re-

paired before use.

Check to see that all moving parts

work properly and do not jam. All

parts must be correctly installed and

meet all conditions necessary for

the proper operation of the electric

tool.

Damaged protection devices or

parts must be repaired or replaced

by an authorised repair centre.

Have damaged switches replaced

by a customer service centre.

Do not operate electric tool if the

switch cannot be turned ON or OFF.

Keep handles dry and free of oil and

grease.

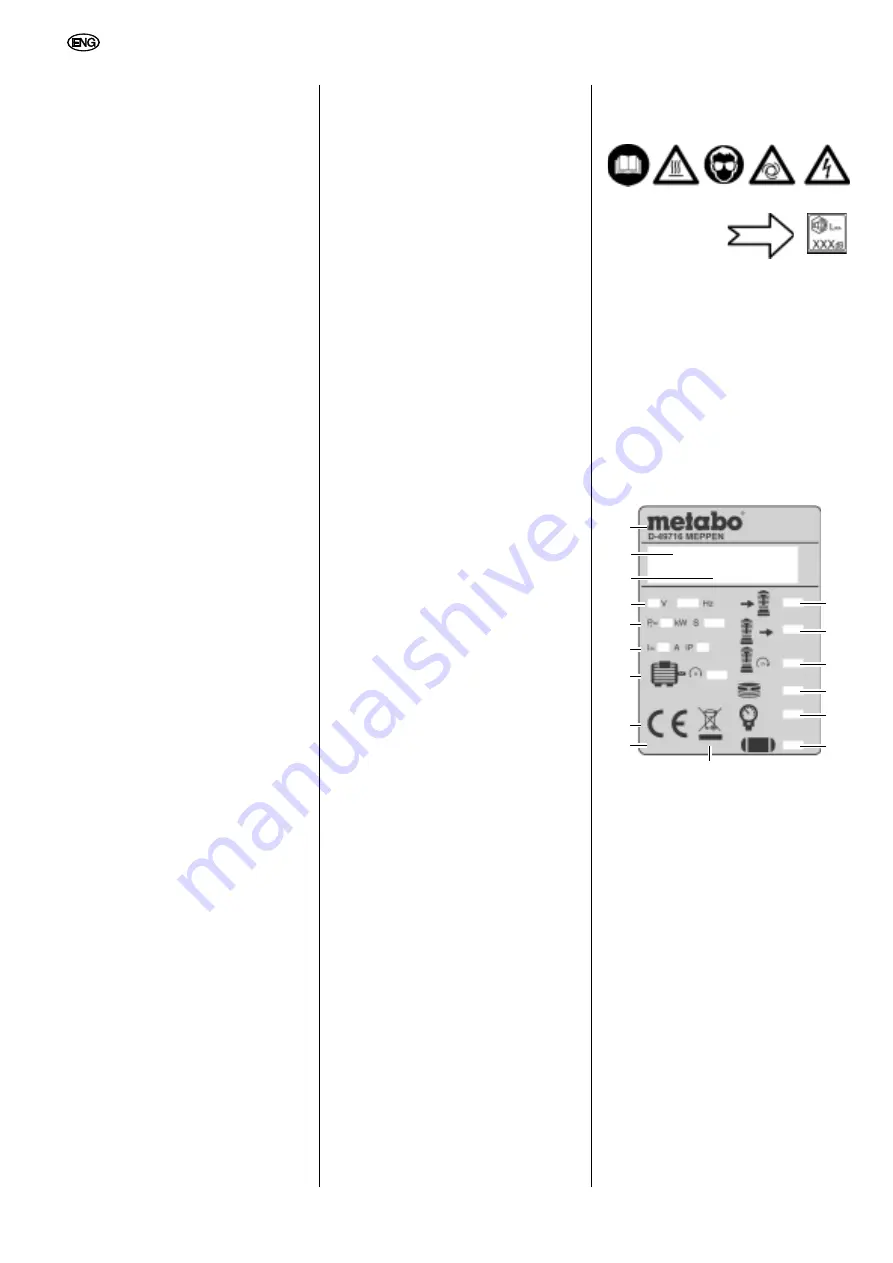

4.3

Symbols on the machine

Symbols on the machine

Information on nameplate:

Read instructions.

Warning that personal injury may

occur through touching of hot

parts.

Wear safety glasses.

Warning of automatic startup.

Warning of high voltage.

Guaranteed sound power level.

Observe direction of rotation.

Manufacturer

Article number, version number,

serial number

Machine designation

Supply voltage / frequency

Motor output P

1

(see also 'Technical data')

Power consumption / Protection

rating

Motor speed / nominal output

power

CE mark – This machine con-

forms to the EC Directives as per

Declaration of Conformity

Date of manufacture

Suction capacity

Filling rate

Speed (compressor pump)

No. of cylinders

18

19

20

21

22

23

24

27

28

29

30

32

35

36

37

38

31

34

39

40

33

25

26