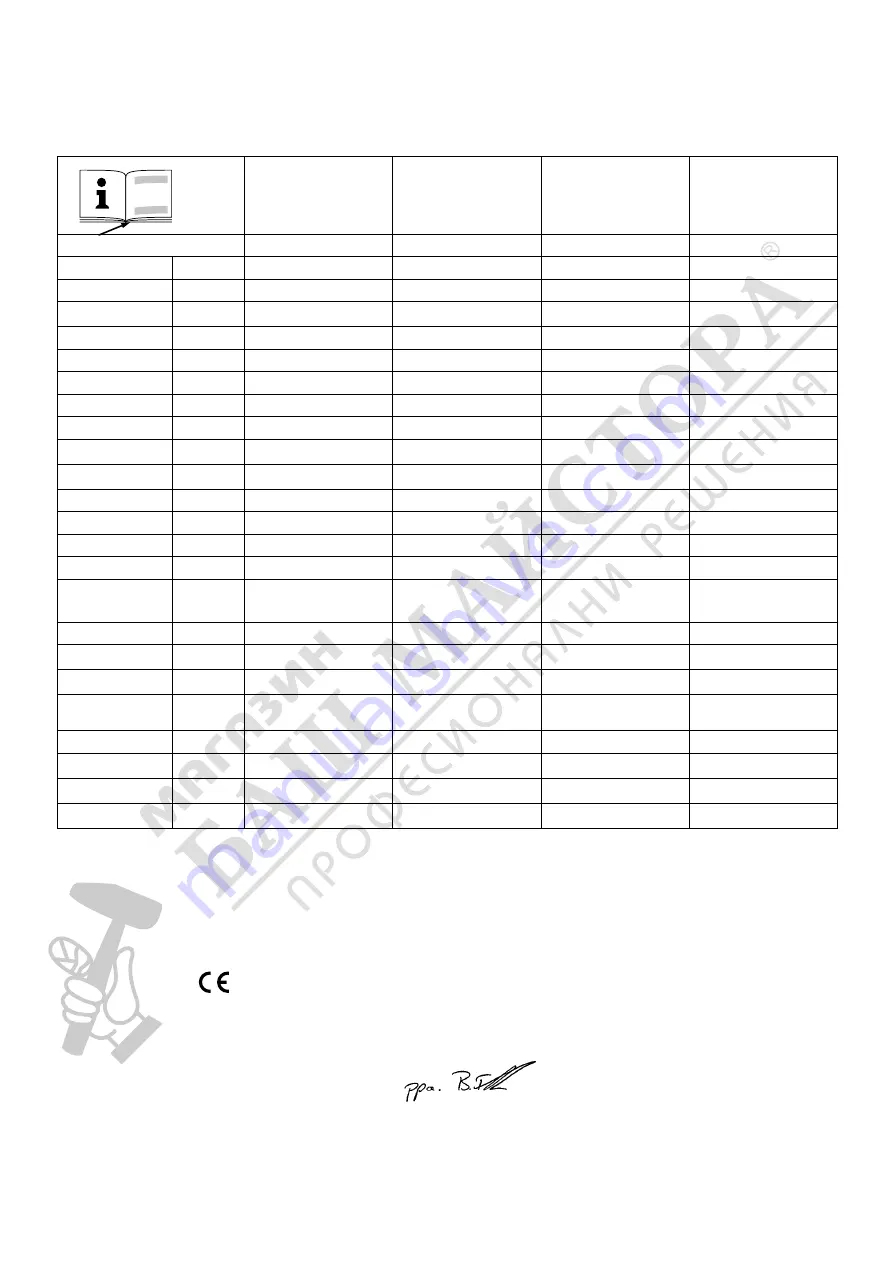

4

Mega 400-50 W

Mega 400-50 D

Mega 550-90 D

Mega 700-90 D

*1) Serial Number

01536..

01537..

01540..

01542..

A

l/min

393

393

510

650

F

l/min

300

300

390

490

L

eff

l/min

255

255

350

420

p

bar

10

10

11

11

V

l

50

50

90

90

a

-

3

3

3

3

z

-

2

2

2

2

Nm

-

22 - 27

22 - 27

22 - 27

22 - 27

n

0

/min, rpm

2900

2900

2900

2900

P

1

kW

2,2 2,2

3,0

4,0

U

V

230 (1~ 50 Hz)

400 (3~ 50 Hz)

400 (3~ 50 Hz)

400 (3~ 50 Hz)

I

A

14,5

4,3

7,6

8,1

F

A

16

6,3

10

10

IP

-

IP 44

IP 44

IP 44

IP 44

G

.

3 x 1,5 mm

2

-> 30 m

3 x 2,5 mm

2

-> 50 m

3 x 1,5 mm

2

-> 30 m

3 x 2,5 mm

2

-> 50 m

3 x 1,5 mm

2

-> 30 m

3 x 2,5 mm

2

-> 50 m

3 x 1,5 mm

2

-> 30 m

3 x 2,5 mm

2

-> 50 m

A

mm

1050 x 410 x 817

1050 x 410 x 817

1126 x 490 x 917

1188 x 520 x 1110

T

max

°C

+ 40

+ 40

+ 40

+ 40

T

min

°C

+5

+5

+5

+5

Oel

-

ca. 0,9 l / SAE 40 (SAE

20)

ca. 0,9 l / SAE 40 (SAE

20)

ca. 1,5 l / SAE 40 (SAE

20)

ca. 1,8 l / SAE 40 (SAE

20)

m

kg

73

73

124

152

L

pA

/K

pA

dB(A)

86 / 3

86 / 3

87 / 3

88 / 3

L

WA

/K

WA

dB(A)

93 / 3

93 / 3

96 / 3

97 / 3

*5) L

WA(M)

/L

WA(G)

dB(A)

89,1 / 93

89,1 / 93

94,8 / 96

95,4 / 97

13.

*2) 2011/65/EU, 2006/42/EC, 2014/30/EU, 2000/14/EC (Annex VIII)

*3) EN 1012-1:2010, EN 60204-1:2006/A1:2009, EN ISO 3744:2010, EN 55014-1:2006/A2:2011,

EN 55014-2:2015, EN 61000-3-3:2013, EN 61000-3-2:2014, EN 50581:2012

*4) Eurofins Product Testing Italy S.r.l. - NB-No. 0477

2018-12-05, Bernd Fleischmann

Direktor Produktentstehung & Qualität (Vice President Product Engineering & Quality)

*6) Metabowerke GmbH - Metabo-Allee 1 - 72622 Nuertingen, Germany