ENGLISH

en

8

Additional Warnings:

California Prop 65 08_2018

Some dust created by power

sanding, sawing, grinding,

drilling, and other construction activities

contains chemicals known to cause cancer,

birth defects or other reproductive harm. Some

examples of these chemicals are:

• Lead from lead-based paints,

• Crystalline silica from bricks and cement and

other masonry products, and

• Arsenic and chromium from chemicallytreated

lumber.

Your risk from these exposures varies, depending

on how often you do this type of work. To reduce

your exposure to these chemicals: work in a well

ventilated area, and work with approved safety

equipment, such as those dust masks that are

specially designed to filter out microscopic

particles.

SYMBOLS ON THE TOOLS:

......... Class II Construction

V............. volts

A............. amperes

Hz........... hertz

.../min ..... revolutions per minute

rpm ......... revolutions per minute

~ ............. alternating current

............ alternating current /direct current

n ............. rated speed

See page 2.

1 Spindle locking button

2 Sliding on/off switch

3 Handle

4 Speed adjustment wheel

5 Electronic signal indicator *

6 Dust filter *

7 Bar auxiliary handle *

8 Thumb screws of the bar auxiliary handle *

9 Locking discs of the bar auxiliary handle *

10 Threaded holes on gear housing

11 Additional handle *

12 Lock button

13 Trigger

* depending on equipment/not in scope of delivery

Before commissioning, check that the rated

mains voltage and mains frequency, as stated

on the type plate match your power supply.

Always install an RCD/GFCI with a maximum

trip current of 30 mA upstream.

Always guide the angle polisher with both

hands on the handles provided.

5.1 PE 15-20 RT: Attaching the additional

handle

Always work with the auxiliary handle (11)

attached! Attach the auxiliary handle on the

left or right of the machine and secure.

5.2 PE 15-30: Fitting of bar auxiliary handle

Always work with the bar auxiliary handle (7)

attached! Fit the bar auxiliary handle as shown

(see illustration A, page 2).

- Fit locking discs (9) to the left and right of the gear

housing.

- Fit the bar auxiliary handle (7) at the gear housing.

- Insert the thumb screws (8) left and right into the

bar auxiliary handle (7) and turn gently.

- Adjust the bar auxiliary handle (7) to the required

angle.

- Firmly tighten the thumb screws (8) to the left and

right manually.

5.3 Dust filter (depending on features)

Assembly see page 2, fig. B.

Regularly clean the dust filter. See chapter 8.

Cleaning.

Press in the spindle locking knob (1) only

when the spindle is stationary!

Locking the spindle

Press in the spindle locking button (1) and turn the

spindle by hand until the spindle locking button

engages.

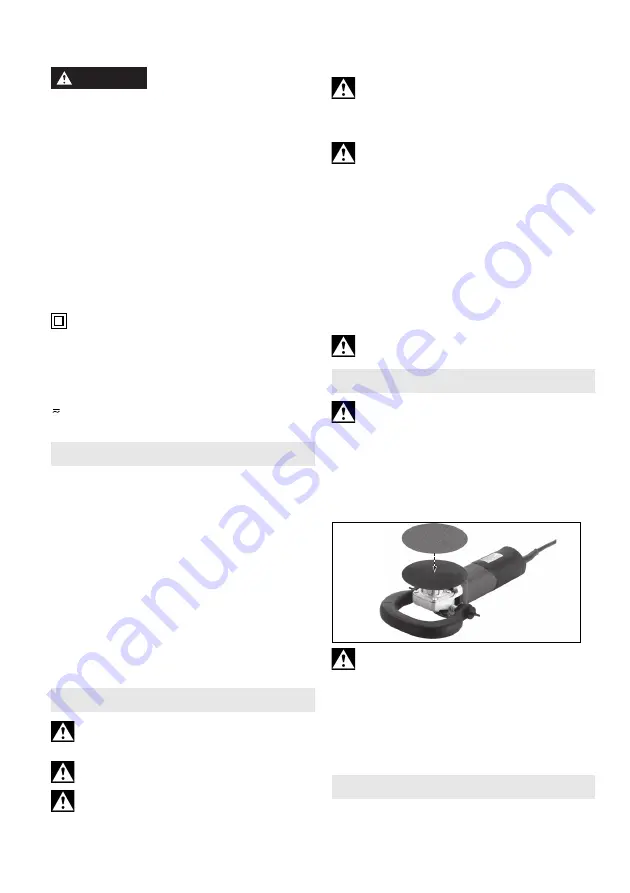

6.1 Installing support plate and sanding

sheet

Only use the adjusting nut supplied with the

support plate.

Place the support plate on the spindle as shown in

the illustration. Screw on sanding sheet with

adjusting nut supplied with support plate. Lock the

spindle. Tighten sanding sheet with support plate

manually in a clockwise direction.

Release by hand or with a two-hole spanner if

necessary.

7.1 Setting speed

The speed can be preset via the thumb-wheel (4)

and is infinitely variable.

4. Overview

5. Initial Operation

WARNING

6. Installing the tools

7. Use

Summary of Contents for PE 15-20 RT

Page 2: ...13 3 1 2 3 4 5 6 1 11 12 4 6 8 9 10 7 A B PE 15 25 B PE 15 20 RT 2...

Page 25: ......

Page 26: ......

Page 27: ......

Page 28: ...Metabowerke GmbH Metabo Allee 1 72622 Nuertingen Germany www metabo com 170 27 508 0319...