8

ENGLISH

1.

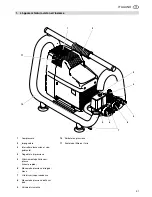

Device overview ..........................7

2.

Please Read First! .......................8

3.

Safety ...........................................8

3.1 Specified conditions of use ...........8

3.2 General safety information ............8

3.3 Safety devices...............................9

4.

Operation .....................................9

4.1 Mains connection ..........................9

4.2 Generating compressed air...........9

5.

Care and Maintenance ................9

5.1 Periodic maintenance....................9

5.2 Device storage ..............................9

6.

Trouble Shooting ........................9

7.

Repairs .......................................10

8.

Environmental Protection ........10

9.

Technical Specifications ..........10

•

Read these instructions before use.

Pay special attention to the safety

information.

•

If you notice transport damage while

unpacking, notify your supplier

immediately.

Do not

operate the

device!

•

Dispose of the packing in an envi-

ronmentally friendly manner. Take

to a proper collecting point.

•

Keep these instructions for refer-

ence on any issues you may be

uncertain about.

•

If you lend or sell this device be sure

to have the instructions to go with it.

3.1

Specified conditions of use

This device is intended to generate com-

pressed air required for the operation of

air tools.

Any use for medical purposes, food

processing as well as filling of oxygen

cylinders for breathing equipment is not

permitted.

Explosive, combustible gases or gases

detrimental to health may not be com-

pressed. Operation in hazardous loca-

tions is not permitted.

Any other use is not as specified. Use

not as specified, alteration of the device

or use of parts that are not approved by

the equipment manufacturer, can cause

unforeseeable damage!

Children, juveniles and persons not hav-

ing been instructed in its usage are not

permitted to operate this device and any

air tools connected to it.

3.2

General safety information

When using this electric tool observe the

following safety instructions, to exclude

the risk of personal injury or material

damage.

Please also observe the special safety

instructions in the respective chapters;

Keep all documents, supplied with the

device, for future reference.

Observe the statuary accident insurance

institution regulations and regulations for

the prevention of accidents pertaining to

the operation of air compressors and air

tools, where applicable.

A

General hazard!

Keep your work area tidy – a messy

work area invites accidents.

Be alert. Know what you are doing. Set

out to work with reason. Do not operate

electric tool while under the influence of

drugs, alcohol or medication.

Consider environmental conditions.

Keep work area well lighted.

Prevent adverse body positions. Ensure

firm footing and keep your balance at all

times.

Do not operate electric tool near inflam-

mable liquids or gases.

Keep bystanders, particularly children,

out of the work area. Do not permit other

persons to touch the tool or power cable

while the electric tool is running.

Do not overload electric tool – use it only

within the performance range it was

designed for (see Technical specifica-

tions).

B

Danger! Risk of electric shock!

Do not expose electric tool to rain.

Do not operate electric tool in damp or

wet environment.

Prevent body contact with earthed

objects such as radiators, pipes, cooking

stoves or refrigerators when operating

this electric tool.

Do not use the power cable for any pur-

pose it is not intended for.

A

Risk of personal injury by

escaping compressed air and parts

hurled about by escaping air!

Never direct compressed air against per-

sons or animals!

Ensure all air tools and accessories

used are designed for the working pres-

sure or are supplied via a pressure regu-

lator.

Please note that, when disconnecting

the quick coupler, the compressed air

contained in the pressure hose will

escape all of a sudden. You should

therefore firmly hold the air hose when

disconnecting it.

Ensure all screwed connections are fully

tightened at all times.

Do not attempt to repair the device your-

self! Only trained specialists are permit-

ted to service or repair compressors,

pressure vessels and air tools.

A

Hazard generated by oil-satu-

rated compressed air!

Use oil saturated compressed air only

for air tools requiring such supply. Do

not use an air hose used to supply com-

pressed air containing oil to supply air

tools not designed for operation on com-

pressed air containing oil. Do not fill tires

with compressed air containing oil.

A

Risk of burns from the sur-

faces of parts carrying compressed

air!

Let device cool off before servicing.

A

Risk of personal injury and

crushing by moving parts!

Do not operate the device without

installed guards.

Please note that the device will start

automatically when the pressure falls off

to minimum! – Disconnect from power

supply prior to any servicing.

Ensure that when switching on (e.g. after

servicing) no tools or loose parts are in

the electric tool.

A

Hazard generated by insuffi-

cient personal protection gear!

Wear hearing protection.

Wear safety glasses.

Wear mask respirator when work gener-

ates dust or mist detrimental to health.

Wear suitable work clothes When work-

ing outdoors wearing of non-slip shoes is

recommended.

A

Hazard generated by electric

tool defects!

Keep electric tool and accessories in

good repair. Observe the maintenance

instructions.

Prior to any use check the electric tool

for possible damage: before using the

electric tool carefully check safety

devices, protection devices or slightly

damaged parts for proper function as

specified. Check to see that all moving

parts work properly and do not jam. All

parts must be correctly installed and

meet all conditions necessary for the

proper operation of the electric tool.

Damaged protection devices or parts

must be repaired or replaced by an qual-

ified specialist. Have damaged switches

replaced by a service centre. Do not

operate electric tool if the switch can not

be turned ON or OFF.

Keep handles free of oil and grease.

Table of Contents

2.

Please Read First!

3.

Safety

Summary of Contents for Power 260

Page 43: ......