ENGLISH

en

15

7 Lock (to prevent the machine from being switched

on unintentionally, or for continuous operation) *

8 Trigger ( for switching on and off) *

9 Additional handle

10 Safety cover

11 Clamping nut *

12 2-hole spanner *

13 Clamping screw

* depending on equipment/not in scope of delivery

Before plugging in, check to see that the rated

mains voltage and mains frequency,

as stated on the rating label, match your power

supply.

6.1 Attaching the additional handle

Always work with the additional handle

attached (9)! Attach the additional handle

on the left or right of the machine and secure.

6.2 Install safety guard

For safety reasons, always use the safety

guard provided for the respective wheel! See

also chapter 11.

Safety guard for grinding

Designed for work with roughing wheels, flap

sanding pads, diamond cut-off wheels.

See page 2, illustration C.

- Slacken the screw (13). Place the safety guard

(10) in the position indicated.

- Turn the safety guard until the closed section is

facing the operator.

- Tighten the screw (13), ensuring that the anti-twist

device engages in the slots.

- Make sure that the guard is seated securely: you

should not be able to turn the safety guard.

Use only accessories that

are covered by at least

3.4 mm by the safety guard.

Disconnect the mains plug before changing

any accessories. The machine must be

switched off and the spindle at a standstill.

For reasons of safety, attach the parting guard

before performing parting work

(see chapter 11. Accessories).

7.1 Locking the spindle

- Press in the spindle locking button (5) and turn the

spindle (4) by hand until the spindle locking button

engages.

7.2 Placing the grinding wheel in position

See page 2, illustration A.

- Place the supporting flange (3) on the spindle (see

illustration above). The flange should not turn on

the spindle when properly attached.

- Place the grinding wheel on the

support flange (3) (see illustration above).

The grinding wheel must lay flat on the supporting

flange. The metal flange on the parting grinder

disc must lay flat on the support flange.

Note: The support flange (3) is secured to prevent it

from falling off. To remove: use some force if

necessary.

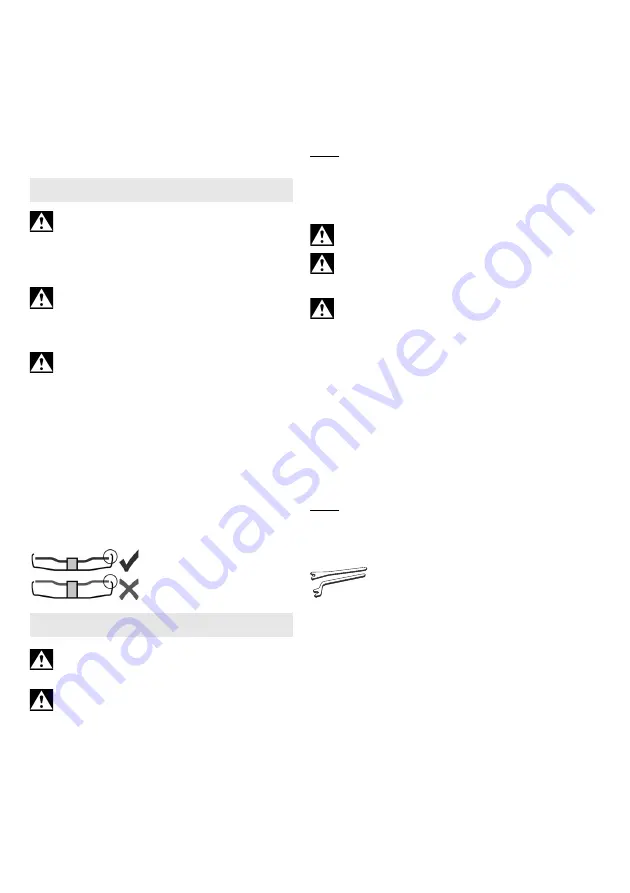

7.3 Securing/releasing the (tool-free)

clamping nut

(depending on features)

Only tighten the (tool-free) clamping nut (2)

manually.

For the machine to operate, the clip (1) must

always lie flat on clamping nut (2) .

To secure the (tool-free) clamping nut (2):

Do not use the (tool-free) clamping nut if the

accessory has a clamping shank thicker than 6

mm! In this case, use the clamping nut (11) with 2-

hole spanner (12).

- Lock the spindle (see chapter 7.1).

- Flip up the clip (1) on the clamping nut.

- Fit the clamping nut (2) on the spindle (4). See

illustration on page 2.

- (1)Tighten the clamping nut

on the clip manually

in a clockwise direction.

- Flip down the clip (1) again .

To release the (tool-free) clamping nut (2) :

- Lock the spindle (see chapter 7.1).

- Flip up the clip (1) on the clamping nut.

- Unscrew the clamping nut (2) , turning it

anticlockwise

manually

.

Note: If the clamping nut is very tightly secured (2),

you can also use a 2-hole spanner to unscrew it.

7.4 Securing/releasing the clamping nut

(depending on features)

Securing the clamping nut (11):

The 2 sides of the clamping nut are different. Screw

the clamping nut onto the spindle as follows:

See page 2, illustration B.

-

A) For thin grinding wheels:

The edge of the clamping nut (11) faces upwards

so that the thin grinding wheel can be attached

securely.

B) For thick grinding wheels:

The edge of the clamping nut (11) faces

downwards so that the clamping nut can be

attached securely to the spindle.

- Lock the spindle. Turn the clamping nut (11)

clockwise using the 2-hole spanner (12) to

secure.

Releasing the clamping nut:

- Lock the spindle (see chapter 7.1). Turn the

clamping nut (11) anticlockwise using the 2-hole

6. Commissioning

7. Attaching the grinding wheel