6

VARIABLE LENGTH

For installations that require non-standard vent lengths, Corr/Guard

Variable Length vent sections may be used. The vent section consists of

an inner conduit that slip fits into the outer conduit, a compression band,

or integral clamp and an outer casing for double wall only.

3”- 5” (76mm-127mm) CG & CGSW

To install the VL vent section, first install the inner pipe section by

connecting the male section to the adjoining double or single wall vent

pipe. Insert male section until the bead of the joint stops at the edge of

the female end of the vent section.

Next, expand the length of the inner pipe to the necessary length and

tighten the integral clamping band using a hex drive or screw driver. The

VL’s are adjustable from 7 1/2” to 22” (191mm to 559mm). Continue with

the next section of vent, making sure to fully join the inner pipe of the

vent from the female end of the VL vent.

When installing double wall, finish the VL vent assembly by installing the

outer casing wall around the VL inner pipe section. Secure the casing

by installing #8x1/2” sheet metal screws at prepunched holes (See

FIG.

14

).

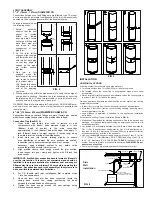

FIG. 15

WARNING: Variable Length sections are not intended to be

subjected to vertical force loads. Use appropriate support

methods.

Supplementary support is required when installing offsets, elbows and

non-vertical runs to prevent unacceptable stresses. Do not allow vent to

sag or deflect from intended flow line during installation.

WARNING: Do not place any type of insulation in any required

clearance spaces surrounding this Vent System.

CONDENSATE DRAINS

If an appliance does not supply a condensate drain and one is required

per the appliance manufacturer’s instructions or local codes, install a

drain fitting in the horizontal conduit, as close as possible to the appli-

ance vent collar.

WARNING: NEVER INSTALL A DRAIN IN A SYSTEM WITH AN

APPLIANCE NOT INVESTIGATED FOR USE WITH A CONDENSATE

DRAIN.

Corr/Guard drain fittings contain a 1/2” (

13mm

) diameter drain tube that

should be located at the bottom of the vent or fitting when installed prop-

erly. A drain hose must be attached to the tube and a trap loop must be

formed into the drain hose. The trap loop should be at least four times the

appliance’s rated stack pressure in inches of water column or 6 inches

(

153mm

), whichever is less. (See

FIG. 16

)

When the Corr/Guard vent system is installed the system must be pres-

sure checked to for tightness. Repair any joint leaks by disassembling

and resealing following the guidelines in the Joint Assembly section of

these instructions. Replace any defective component.

The Corr/Guard ventilation system, manufactured by Metal-Fab, Inc..

is constructed to exacting standards. The proper operation of this vent

system is dependent on the use of correct components, proper sizing,

quality of installation, and guidelines and limitations expressed by the

appliance manufacturer.

TUBING

TRAP LooP

(4x STACK PRESSURE)

FIG. 16

6”- 24” (152mm-610mm) CG & CGSW

To install the VL, first apply a heavy bead of P077 Sealant into the inner

vent groove. Then slide the inner vent into the outer vent. Locate into

position and adjust to proper length. Follow Joint Assembly Details on

PAGES 2 & 3

. Apply a bead of P077 Sealant at the joint of inner and

outer vent and attach compression band. The 6” VL is adjustable from

7½” to 10” (191mm to 254mm) and the 12” (305mm) VL is adjustable

from 13½” to 22” (343mm to 559mm). When installing double wall, cut

outer jacket to fit between the mating vent and install using sheet metal

screws (supplied) (See

FIG 15

).

INNER FLUE

CASING JACKET

INTEGRAL CLAMP

FIG. 14

COMPRESSION

BAND

OUTER

JACKET

FOR CG

ONLY

GROOVE

OUTER CONDUIT

INNER CONDUIT

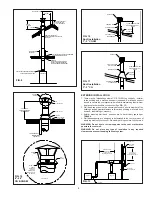

SMALL DIAMETER CGSW & CG TO CGSW & CG

Connections between vent and fittings are male / female type, sealed

with silicone sealant and secured with a profiled closure band. (See

FIG.

17

)

Connection Tips:

1. Clean male and female joint ends to remove oil and

contaminants with alcohol pads provided. Apply a ¼ inch

(

6.4mm

)

bead

of

sealant

to

the

male

connection

approximately ¼ inch (

6.4mm

) below the edge. Also apply ¼

inch (

6.4mm

) bead of sealant (approx. 2 inches long) along

the male joint at the overlap of the welded seam.

2.

Insert male end into female, twisting slightly, to ensure

even distribution of sealant. Be sure sections are seated.

Inspect the joint to ensure that vent gases will not escape.

If necessary, apply additional sealant to any visible voids

around the joint and smooth it into crevices.

3. Align profiled closure band snugly around the joint section.

Insert tongue into gear clamp and tighten with 3/8-inch hex

drive socket.

IMPORTANT: Profiled Vent connection band is formed to fit exactly

over the joint section. This part is not symmetrical and should be

installed in the proper orientation for maximum seal and support.

Allow sealant to cure for a minimum 24 hours before operating the

appliance. Any adhesives used in the assembly of the system are to

be used within their marked time limitations.

4. For CG (double wall) joint installations, first complete steps

1 thru 3 as shown above.

5. Once the inner vent joint has been connected, locate the

casing

band

around

the

casing,

positioning

the

band

between the formed beads on either casing.

6.

Tighten the band snugly around the vent casings using

3/8-inch hex drive socket.