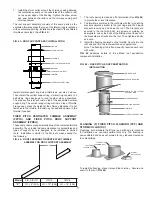

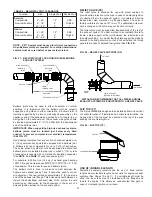

90º WYE (90Y)

The 90º wye is very useful when the vertical chimney is located

between two appliances and a low-loss junction is desired. It is

ideal for engine with dual-exhaust connections. The wye fitting

may be suspended by a plate support or roof support assembly.

Expansion joints or bellows joints should be used to protect the

wye from thermal expansion stresses (See

FIG. 19

).

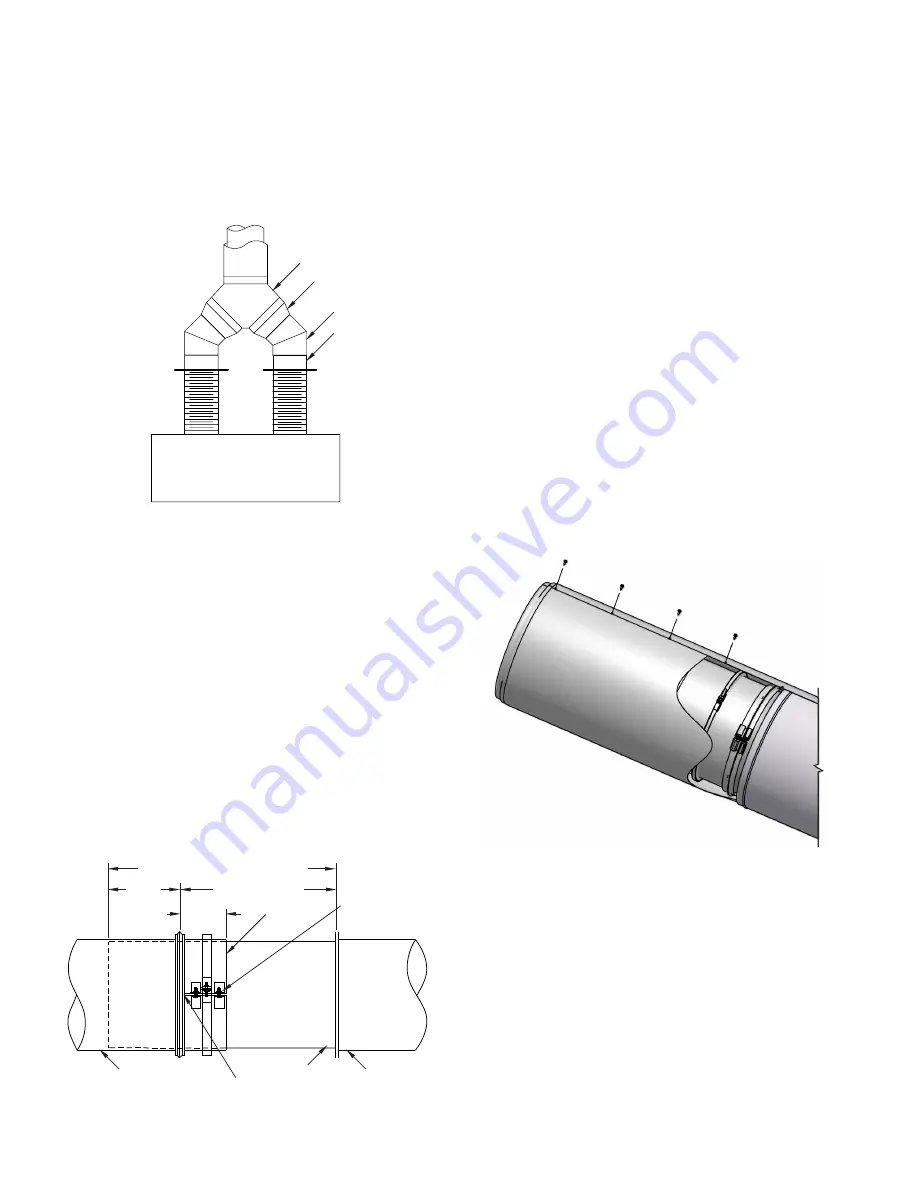

EXPANSION JOINT (AL)

The expansion joint may be used to compensate for thermal

expansion and to make up odd lengths. It is essential that

sufficient installed length be allowed to compensate for abnormal,

as well as normal, operating conditions. The expansion joint

cannot be used to correct misalignment or to compensate for

lateral movement or vibration. The use of the expansion joint in

engine exhaust applications is not recommended.

An expansion joint is comprised of: (1) a collar that is 5¼” (133)

long with a flange and vee band at one end and a graphite

impregnated ring gasket at the other; (2) a 30” (762) long tube,

flanged at one end, which fits into the 5¼” (133) collar; (3) an

outer jacket consisting of two half jacket assemblies; and (4)

loose insulation blanket to fill space between the tube and

casing.

Installation procedure is as follows:

1. Loosen draw screw at gasket band and slide collar toward

flanged end of tube. Do not remove collar from tube.

2. Slide unflanged end of tube into the upstream piece of pipe

and make up joint between pipe and collar following the

procedures outlined under heading JOINT ASSEMBLY on

Page 4.

3. Pull flanged end of tube to the downstream piece of pipe and

make up joint as above (See

FIG. 20

).

4. For IPIC, cut insulation to desired length and wrap inner pipe

ensuring that it is covered completely before attaching half

jackets.

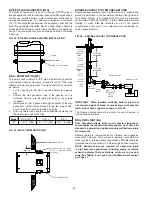

5. Wrap two half jackets around joint with bead at the

downstream end and punched edge overlapping plain edge

by approximate 3/4” (19).

NOTE:

For horizontal installations

the seams must be located at the top and bottom of the

pipe, coat unpunched edge of casing with P077 sealant to

waterproof the casing.

6. Install self-drilling screws (supplied with jacket) at punched

holed through both layers at overlap. Exercise care that half

jacket edges do not align with draw screws on flange bands

and that no screws are installed in portion of jacket which is

over casing of adjacent pieces of pipe (See

FIG. 21

). The

screws shipped with the expansion joint are of the correct

length to avoid penetrating the inner wall (flue) of the pipe.

Do not use any other screws to attach the casing.

FIG. 19 – 90º WYE APPLICATION, DUAL EXHAUST

ENGINE WITH

DUAL EXHAUSTS

90° WYE

TAPERED INCREASER

45° FIXED ELBOW

FLANGE ADAPTER

10

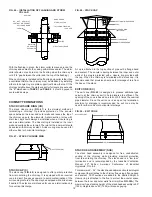

FIG. 21 - EXPANSION JOINT CASING ASSEMBLY

Note: Do not screw through casing of adjacent pipe.

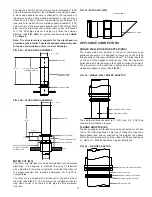

FIG. 20 – EXPANSION JOINT FLUE ASSEMBLY

30” MAX. (762) OR TRIMMED AS REQ’D

8” MIN.

(203)

INSTALLED LENGTH

3-3/4”

(95)

COLLAR

PIPE

UNFLANGED END

RETAINING

SCREWS

ADJOINING PIPE

(UP SLOPE)

APPLY SEALANT

UNDER SEAM

(REF. JOINT ASSY. FOR

PROPER SEALANT)

ADJOINING PIPE

(DOWN SLOPE)