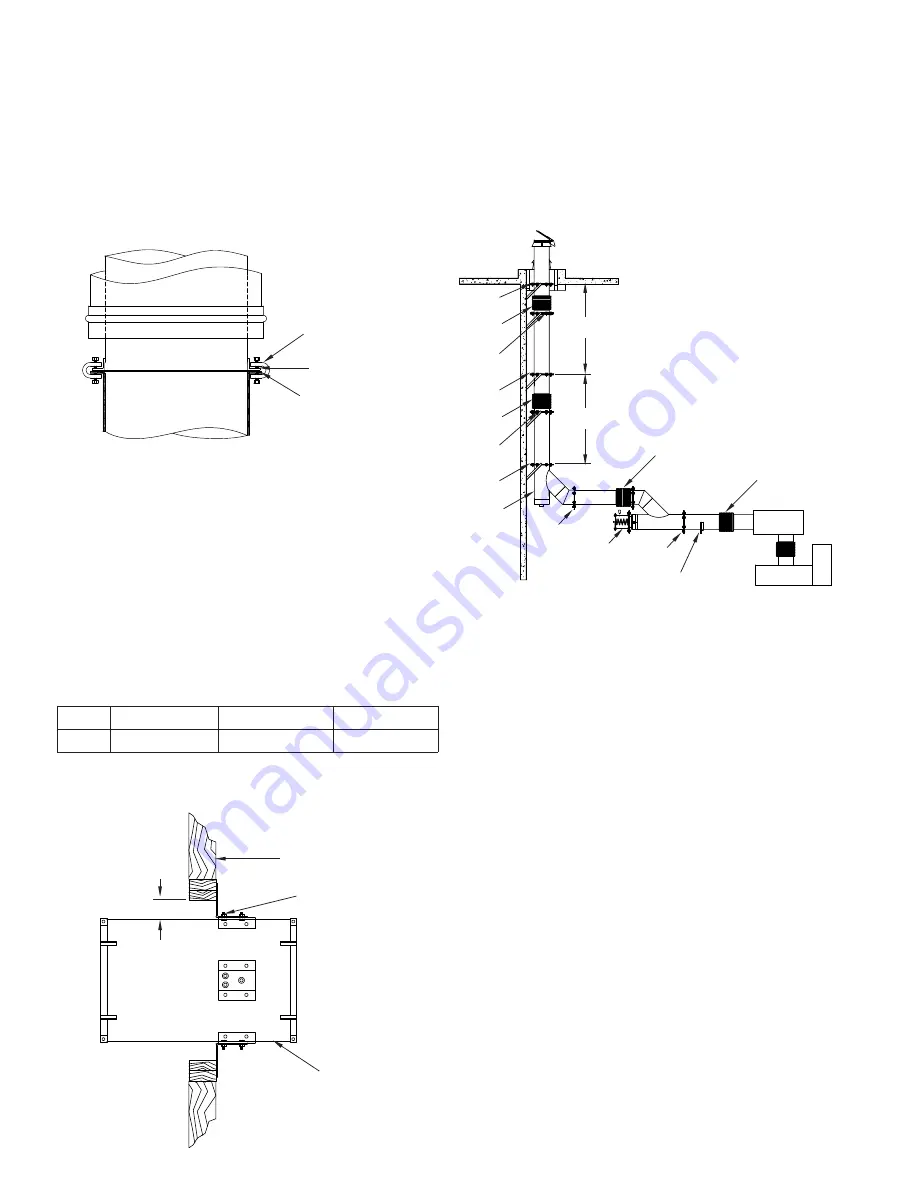

ENGINE EXHAUST SYSTEM PRECAUTIONS

Engine exhaust systems require extra attention to support and

protection detail due to the possibility of delayed fuel ignition in

the exhaust system. It is important that all turns are protected

as illustrated in

FIG. 14, 16 & 18

or rigidly attached to structural

framing or walls.

FIG. 56

illustrates some of the special

considerations that must be considered when designing an

engine exhaust system.

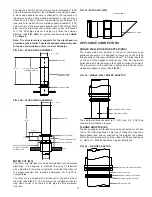

IMPORTANT: When installed vertically, bellows joint must

not support weight of stack. Locate bellows joint near the

lower side of fixed support as shown in FIG. 55.

The following components are primarily for use on engine or

turbine exhaust systems.

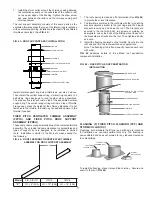

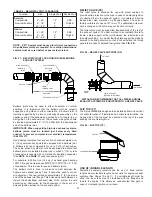

FIG. 55 - WALL PENETRATOR (WP)

4” MIN. (102)

COMBUSTIBLE WALLS

ATTACHED WITH 8D NAILS

OR #10 - 2” WOOD SCREWS

(4 PLACES)

WALL PENETRATOR

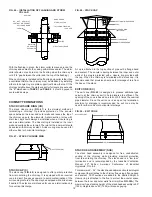

FIG. 56 – ENGINE EXHAUST CONSIDERATIONS

PLATE

SUPPORT

BELLOWS

JOINT

PLATE

SUPPORT

BELLOWS

JOINT

WALL

GUIDE

WALL

GUIDE

PLATE

SUPPORT

FIXED

TEE

PLATE

SUPPORT

PLATE

SUPPORT

BELLOWS JOINT

HALF

ANGLE

BELLOWS JOINT

MUFFLER

ENGINE

RELIEF

VALVE

3” (76) MAX.

EXPANSION

3” (76) MAX.

EXPANSION

20

BELLOWS JOINT (BJ)

Note: Standard bellows joints require greater clearance to

combustibles that double wall components. See Table 9 for

standard single wall and optional double wall bellows joints

for clearances.

Bellows joints are recommended for vibration and expansion

movement. This type of movement is typically encountered in

diesel engine or turbine exhaust applications.

FIG. 56

illustrates

typical bellows joint locations in a diesel engine exhaust system.

NOTE: Bellows Joints are required for expansion joints

in high pressure applications including engine or turbine

exhaust. Systems that use Bellows Joints are to use seal

clips (See TABLE 4 on Page 5) and additional joint sealant

per Page 23.

WALL PENETRATOR (WP)

This part is used to allow PIC/IPIC pipe to pass through non-fire

rated walls at reduced clearance. It consists of a 30” (762) long

thimble with mounting brackets. The wall penetrator is mounted

as follows:

1. Cut the opening in the wall. See chart below for opening

size.

2. Position the wall penetrator tube in the opening so it is

centered. Secure it to the wall with bolts or lag screws

(supplied.)

3. Install pipe so that it passes through the center of the wall

penetrator. Install lateral braces around the pipe casing.

Leave rings loose enough to slide along pipe.

4. Push the lateral rings into the wall penetrator centering the

tabs within the ends of the tube.

Model

PIC & IPIC-1

IPIC-2

IPIC-4

“X”

I.D. + 8” (203)

I.D. + 10” (254)

I.D. + 14” (356)

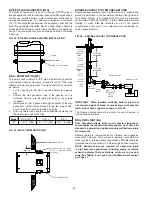

BOILER FLANGE ADAPTER (BFA)

The boiler flange adapter is used to connect PIC/IPIC pipe to

flanged appliance outlets other than those with ANSI pipe flanges.

Typical use includes boilers, water heaters and connection to

existing fabricated pipe. The adapter is designed to sandwich

the 1/2” inner pipe flange between the appliance outlet and the

boiler flange adapter (See

FIG. 54

). The boiler flange adapter is

shipped with beam clips used to clamp the BFA to the appliance

flange. The connection may also be drilled and bolted or welded

if desired.

FIG. 54 - BOILER FLANGE ADAPTER INSTALLATION

CLAMP

HALF RING

BOILER OUTLET FLANGE