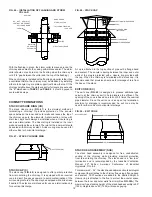

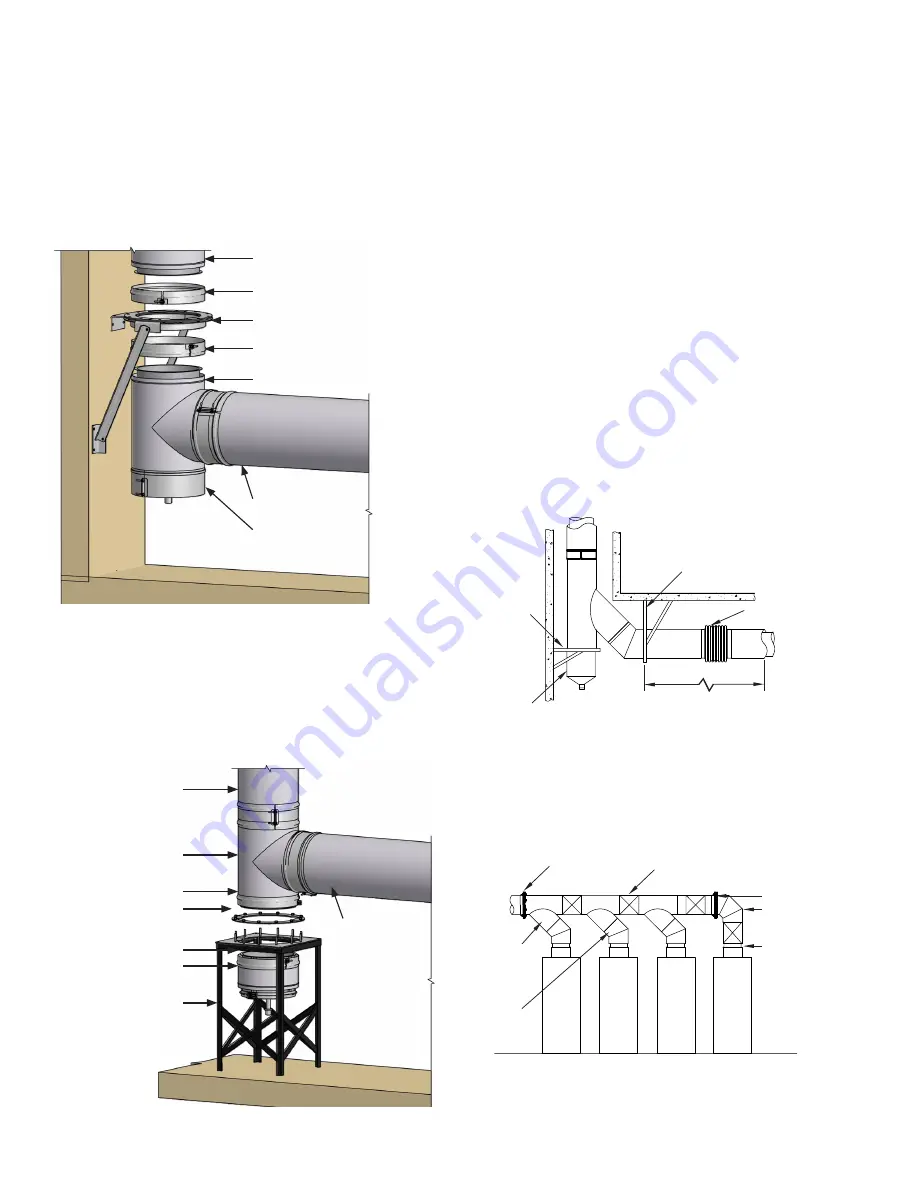

45º MANIFOLD TEE (45MT), DOUBLE LATERAL (DL)

For systems where minimizing flow resistance is desirable

or critical, a manifold tee having a 45º entrance to the trunk

is available. When used to make 90º turns, an additional 45º

elbow is required. It is particularly important to isolate the 45º

manifold tee from the effects of thermal expansion. This isolation

is typically accomplished by the use of a 2-axis support (See

FIG. 14

). Otherwise, the installation details and precautions are

similar to those for the 90º manifold tee.

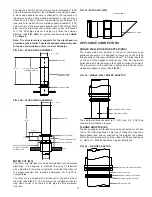

MULTIPLE APPLIANCE BREECHINGS (HEADERS)

When 90º or 45º manifold tees are used to manifold multiple

appliances together, it is important to make provisions for

expansion of the manifold. An expansion joint should be installed

between tees (See

FIG. 15

). The manifold must be supported

properly by means of plate supports or wall support assemblies

arranged to protect the tees from bending forces.

30º, 45º OR 90º FIXED ELBOWS (30L) - (45L) - (90L)

Elbows are not designed to resist bending loads and must be

protected by structural reinforcement.

FIG. 16

depicts some

alternative methods for protection of elbows. Elbows may be

FIG. 14 - TWO-AXIS SUPPORT METHOD

MORE THAN 1/4” THERMAL

EXPANSION EXPECTED

BELLOWS JOINT OR

EXPANSION JOINT

PLATE SUPPORT ATTACHED

TO BUILDING STRUCTURE

DRAIN BUCKET

WALL SUPPORT

ASSEMBLY

FIG. 15 – LATERAL TEE MANIFOLD

PLATE SUPPORT

ADJUSTABLE LENGTHS

OR BELLOWS JOINT

PLATE SUPPORT

90° ELBOW

OUTLET

45° MANIFOLD

TEE

45° FIXED

ELBOW

8

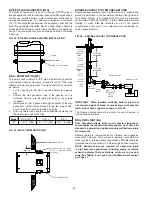

STANDARD 90º TEE (90MT)

The 90º Manifold Tee (90MT) may be used to connect horizontal

to vertical when a cleanout access or drain is desired. If more

than 1/4” (6) of thermal expansion is expected between the

tee and the next fixed support point (the appliance outlet, for

example), the tee should be protected from bending moments

by use of an expansion joint or bellows joint. See the sections on

those fittings for additional information about compensation for

thermal expansion.

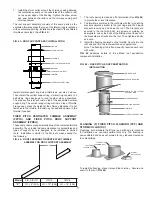

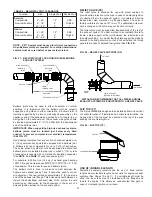

FIG. 12 – SUSPENDED TEE

PIPE RISER

HALF CLOSURE BAND

WALL SUPPORT ASSEMBLY

HALF CLOSURE BAND

TEE AT BASE OF RISER

DRAIN TEE CAP

PIPE SECTION

When a tee is used at the base of a riser, the preferred location

for support is above the tee, thus suspending the tee (

FIG. 12

). If

it is not possible to suspend the tee, it may be supported from the

base of the tee (

FIG. 13

). When this type of support is necessary,

access to the drain cap may be hindered. A drain bucket should

be used under the tee to allow access to the tee cap.

FIG. 13 – BASE SUPPORTED TEE

PIPE RISER

TEE

HALF CLOSURE BAND

CLAMP RING

(SEE NOTE BELOW)

HALF CLOSURE BAND

DRAIN BUCKET

STRUCTURAL STEEL

STAND (BY OTHERS)

PIPE SECTION

DRAIN TEE CAP (TC), CLEANOUT CAP

The unused port of a tee must be closed to prevent leakage of

flue gases. A drain tee cap is used to close the tee and drain

condensation or rainwater when the tee is installed at the base of

a rise. When the tee is to be used for cleanout or access purpose

only, a cleanout cap (TCN) is recommended. Both the drain tee

cap and the cleanout cap are equipped with closures, which

serve the dual purpose of maintaining the double wall clearance

to combustible and giving the cap a finished appearance.

The drain tee cap’s drain nipple must be connected to a suitable

disposal point. Any rain entering the chimney will wash down

and remove any combustion residue from the chimney flue. The

resulting effluent may be corrosive. The tee cap must be sealed

at the connection to the tee using the appropriate sealant for the

application. This will assure that moisture will drain through the

drain nipple, as intended.