18

9

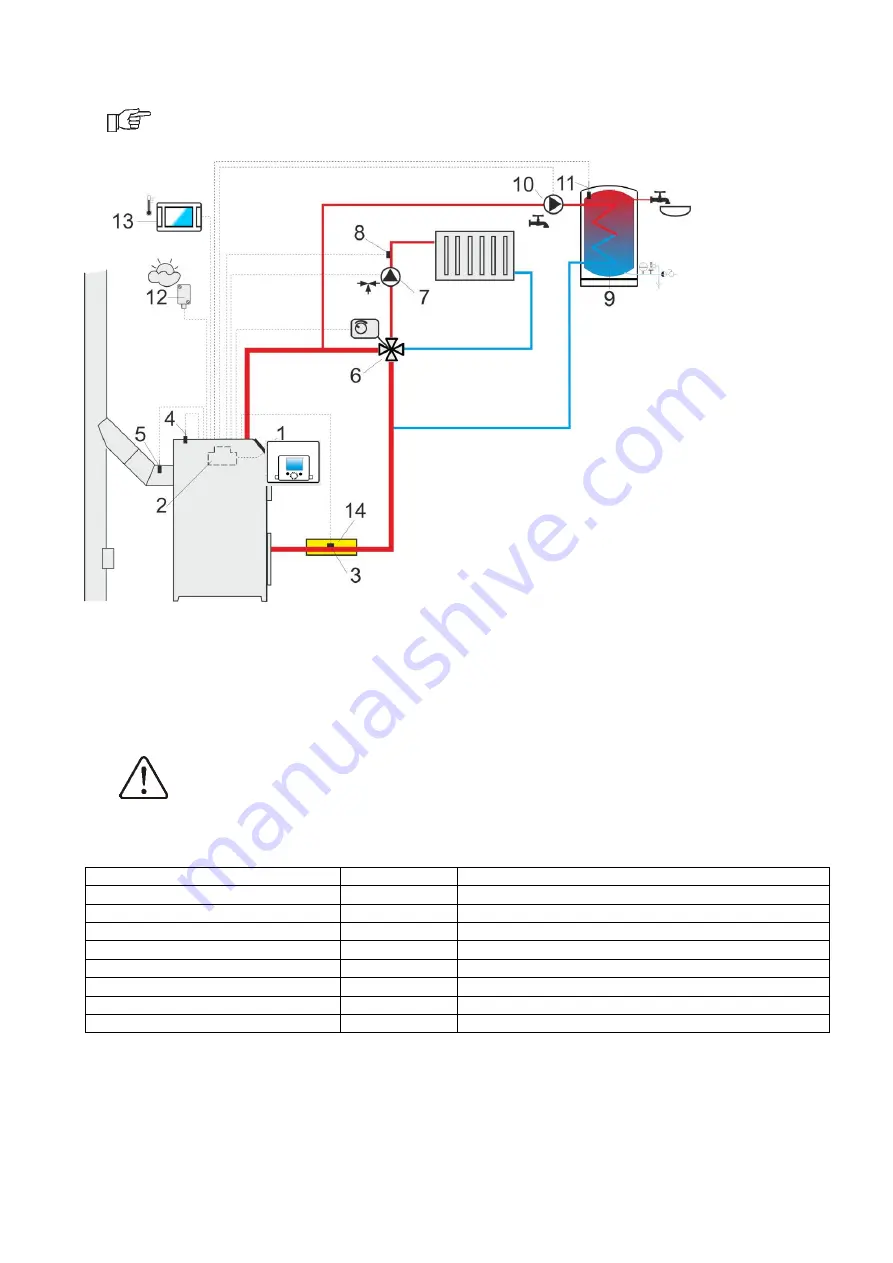

Hydraulic diagrams

The presented hydraulic diagram does not replace central heating engineering

design and may be used for information purposes only.

Diagram with 4-way control valve for central heating circuit: 1 – boiler, 2 – controller, 3 - water

temperature sensor returning to the boiler, 4 – boiler temperature sensor, 5 – exhaust temperature sensor

(temperature monitoring only), 6 – 4-way valve servo, 7 – mixer circuit pump, 8 – mixer circuit temperature

sensor, 9 – HUW container, 10 – HUW pump, 11 – HUW sensor, 12 – weather temp. sensor, 13 – ecoSTER

TOUCH room control panel or standard room thermostat, 14 – thermal isolation.

In order for the valve (6) to be able to effectively increase the return water temperature,

set a high set temperature of the boiler. In order to improve the water circulation in

natural systems (highlighted circuit in the figure): use large nominal diameter pipes and

four-way valve, avoid unnecessary angles and reductions, maintain a min. 2° horizontal

pipe slope, etc. If the sensor (3) is attached to the pipe, isolate it with foam surrounding

the pipe and sensor.

RECOMMENDED SETTINGS:

Parameter

Setting

MENU

Preset boiler temperature

75-80

C

menu

Boiler settings

Min. preset boiler temperature

65

C

menu

Service settings

Boiler settings

Increasing of preset boiler temp.

5-20

C

menu

Service settings

CH and HUW settings

Mixer 1 support

CH ON

menu

Service settings

Mixer 1 settings

Maxer 1 preset temperature

70

C

menu

Service settings

Mixer 1 settings

Mixer 1 heating curve

0.8 – 1.4

menu

Mixer 1 settings

Mixer 1 weather control

ON

menu

Mixer 1 settings

Mixer 1 thermostat selection

ecoSTER T1

menu

Service settings

Mixer 1 settings

Summary of Contents for ecoMAX860P TOUCH

Page 2: ......

Page 6: ...6...

Page 7: ...INSTRUCTION MANUAL ecoMAX 860P TOUCH...

Page 17: ...INSTALLATION AND SERVICE SETTINGS ecoMAX 860P TOUCH...

Page 43: ......