26

12.6

Connection of temperature

sensors

The regulator is compatible only with CT4

and CT2S sensors. The use of other sensors

is prohibited!.

Wires of sensors can be extended by wires

with diameter no smaller than 0,5mm

2

. Total

length of wires in each sensor should not

exceed 15m.

The boiler temperature sensor should be

installed in a thermostatic pipe installed in

the boiler. Temperature sensor of hot water

silo should be installed in a thermostatic pipe

welded into the silo. The mixer temperature

sensor should be installed in a sleeve located

in stream of running water in pipe, but also it

can be installed on the pipe, on condition

that it is thermally isolated from the pipe.

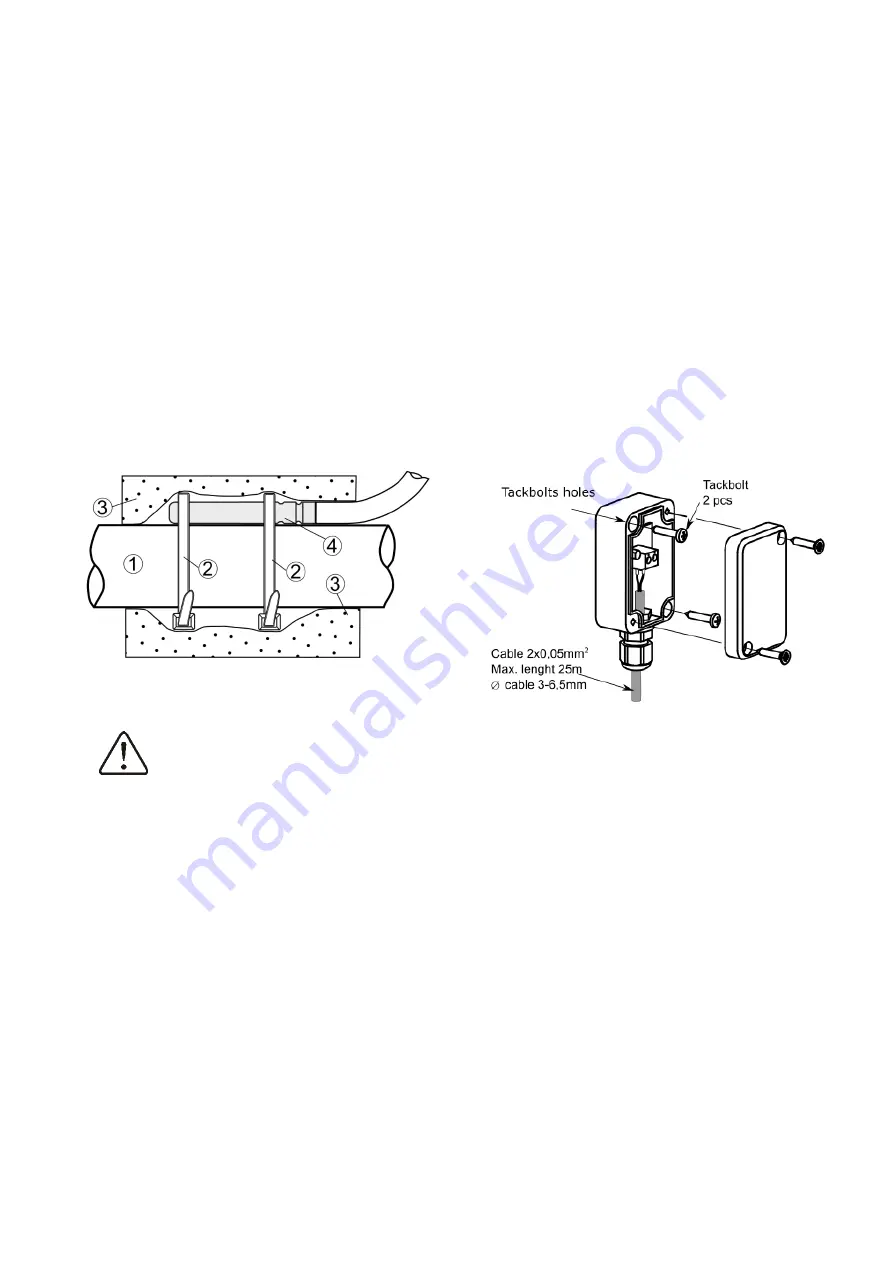

Mounting temperature sensor: 1 - pipe, 2 –

clamps, 3 - thermal insulation, 4 - temperature

sensor.

Sensor must be protected from

getting loose from the surfaces

to which they are connected.

Good thermal contact should be maintained

between sensors and the measured surface.

To this purpose thermal grease should be

used. It is not acceptable to lubricate sensors

with water or oil. Wires of sensors should be

separated from network electrical wires. In

such a case wrong readings of temperature

may be shown. Minimum length between

those wires should be 10 cm. It is not

acceptable to allow for contact between wires

of sensors and hot parts of the boiler and the

heating installation. Wires of sensors are

resistant to temperature not exceeding

100°C.

12.7

Connecting weather sensor

he regulator cooperates solely with the

weather sensor type CT6-P. The sensor

should be installed on the coolest wall of the

building. Usually it is the northern wall,

under the roof. The sensor should not be

exposed to direct sunrays and rain. The

sensor should be installed at least 2 m above

the ground, far away from windows,

chimneys and other sources of heat.

To make the connection use wire with

diameter at least 0,5mm2 up to 25m long.

Polarization of wires is not essential. Second

end should be connected to terminals of the

regulator or properly to the used kind of

regulator.

The sensor should be screw to the wall.

Access to assembly holes is possible after

unscrewing the cover of the sensor.

12.8

Connecting exhaust sensor

The exhaust sensor should be fitted in the

boiler flue. The gap between the sensor and

the flue should be sealed. The sensor should

be installed by a qualified fitter, while

observing regulations applicable for chimney

systems. The emission sensor should be

connected to the sensor terminals acc. to

The emission sensor lead cannot touch hot

elements of the boiler and the flue, the

temperature of which exceeds 350°C. The

emission sensor should be installed in such

distance from the boiler at which it is not

directly exposed to flames, and where the

emission temperature does not exceed

450°C.

Summary of Contents for ecoMAX860P TOUCH

Page 2: ......

Page 6: ...6...

Page 7: ...INSTRUCTION MANUAL ecoMAX 860P TOUCH...

Page 17: ...INSTALLATION AND SERVICE SETTINGS ecoMAX 860P TOUCH...

Page 43: ......