23

11

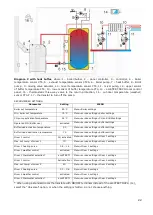

Technical data

Voltage

230V~; 50Hz;

Current consumed by regulator

I = 0,04 A

Maximum rated current

6 (6) A

Regulator protection rating

IP20

Ambient temperature

0...50

C

Storage temperature

0...65

C

Relative humidity

5 - 85% without

steam condensation

Measuring range of

temperature sensors CT4

0...100

C

Measuring range of

temperature sensors CT6-P

-35...40

C

Accuracy of temperature

measurements with sensors

CT4 and CT6-P

2

C

Terminals

network

screw terminals, wire

cross-section area

0.75 mm

2

through

1.5mm

2

, screwing

torque 0.4Nm,

insulation removed:

6mm

communication

screw terminals, wire

cross-section area up

to 0.75mm

2

,

screwing torque 0.3

Nm, insulation

removed: 6 mm

Display (TOUCH)

Color display

480x272 with touch

panel

External dimensions

210x115x60 mm

Total weight

2 kg

Standards

PN-EN 60730-2-9

PN-EN 60730-1

Software class

A

Protection class

Suitable to build into

Class I devices

Pollution degree

2nd degree according

to PN-EN 60730-1

12

Conditions of storage and

transport

The regulator cannot be exposed to direct

effects of weather, i.e. rain and sunlight.

Storage and transport temperature cannot

exceed the range of -15…65 °C.

During transport, the device cannot be

exposed to vibrations greater than those

typical of normal road transport.

13

REGULATOR INSTALLATION

13.1

Environmental conditions

Due to the risk of fire is prohibited to use the

controller in explosive gas and dust

enviroment (eg coal). Regulator should be

separated using appropriate enclosure.

In addition, controller cannot be used in the

presence of water vapor condensation and be

exposed to water.

13.2

Installation requirements

The regulator should be installed by a

qualified and authorised fitter, in accordance

with the applicable norms and regulations.

The manufacturer bears no responsibility for

damages caused by failure to observe this

manual. The regulator is to be built-in. The

regulator cannot be used as a stand-alone

device. The temperature of the ambient and

the fitting surface cannot exceed the range

of 0 - 50˚C. The device consists of two

modules: control panel and working module.

Both elements are connected with electric

wire.

13.3

Assembly of TOUCH control panel

The Control Panel is intended to be installed

in a mounting plate. Make sure there is

sufficient thermal insulation between the hot

walls of the boiler and the control panel and

wiring. The amount of space needed to

properly install the control panel is illustrated

below. Follow the guidelines below when

installing the Panel.

Make an opening in the mounting plate

according to the following illustration.

Summary of Contents for ecoMAX860P2-T

Page 2: ...2...

Page 6: ......

Page 7: ...REGULATOR INSTRUCTION MANUAL ecoMAX860P2 T...

Page 19: ...19 CONTROLLER INSTALLATION AND SERVICE SETTINGS MANUAL ecoMAX860P2 T...

Page 43: ......

Page 44: ......

Page 45: ......

Page 46: ......

Page 47: ......