CorrTran MV Corrosion Monitor

15

3.3 Mounting safety procedures and hints

The CorrTran MV must be installed in locations that are most susceptible to corrosion.

In most cases, the highest levels of corrosion tend to occur where water is trapped or

stagnant.

The electrodes selected must reflect the same metal properties as the piping or other

components susceptible to corrosion. For example, in applications where the pipe is made

of stainless steel and the water pump’s impeller is made of carbon steel, the impeller will

corrode faster than the pipe. In this case, it is advisable to select electrodes that are made

of the same material as the pump’s impeller.

3.3.1 Mounting requirements / scenarios

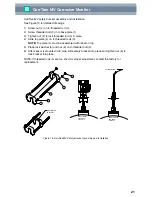

The transmitter should not be mounted in a pipe drop since the corrosive liquid

may not be in full contact with the electrodes as shown in Figure 8.

CorrTran MV should be mounted in the riser of a pipe near an elbow where the

velocity is the highest. In general, CorrTran MV should be mounted in pipes

or tanks at locations of highest liquid velocity and constant immersion, shown

in Figure 9. For velocities greater than 20 fps, the protruding finger electrodes

must be protected. As noted above, high fluid velocities can also cause unwanted

turbulence in the pipe due to the extension of the probe. Using an adjustable CorrTran MV

probe with electrodes mounted flush to the wall of the pipe will eliminate this problem.

Warning

Attention

OK!

Figure 8. CMC Transmitter Installation

Figure 9. CMC Transmitter Installation